ATE (automatic test equipment) with mechanical hand and control method thereof

A technology of testing equipment and manipulators, applied in sorting and other directions, can solve problems such as increasing enterprise costs and reducing work efficiency, and achieve the effects of improving testing efficiency, saving manpower, and improving quality inspection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

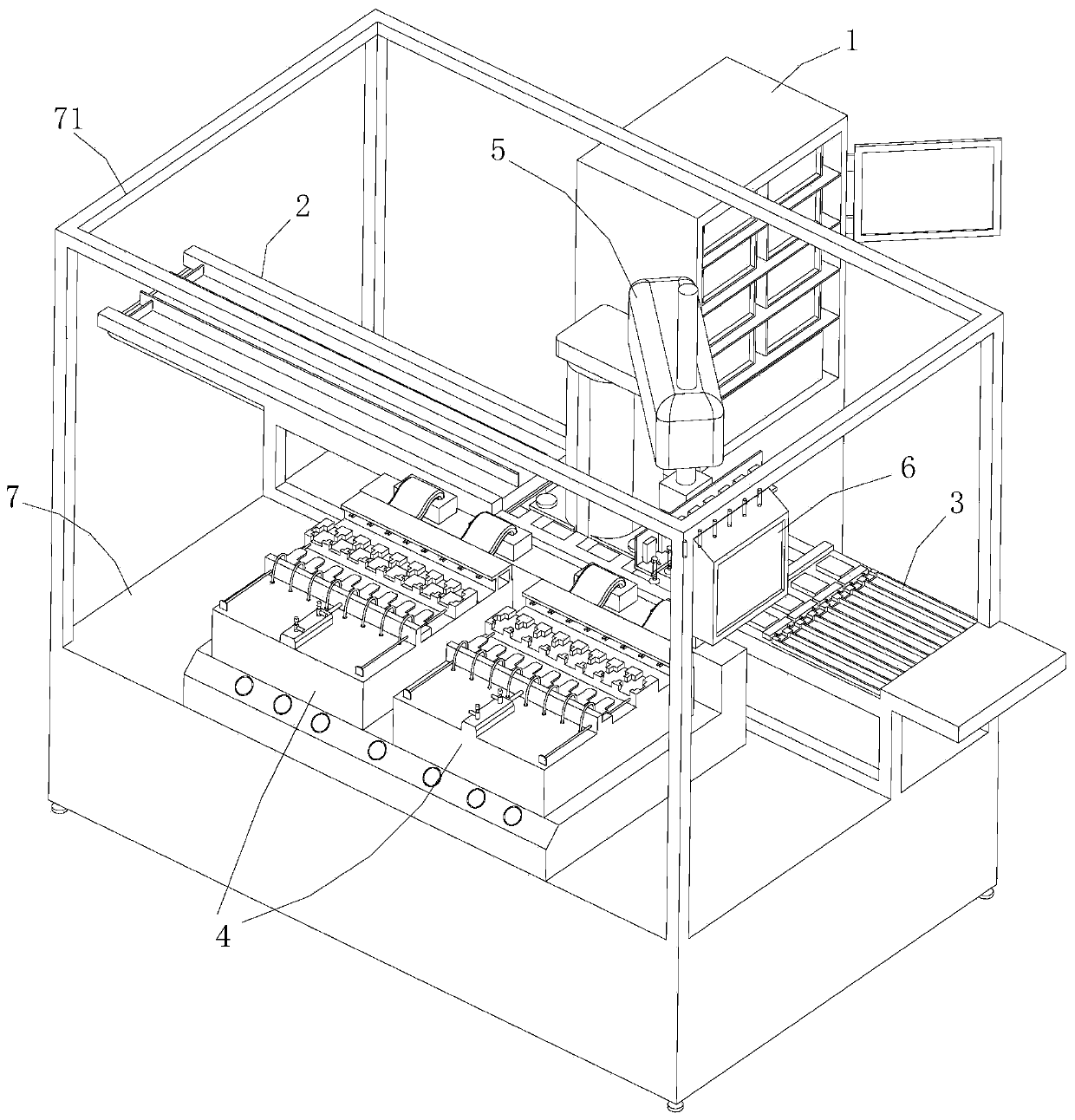

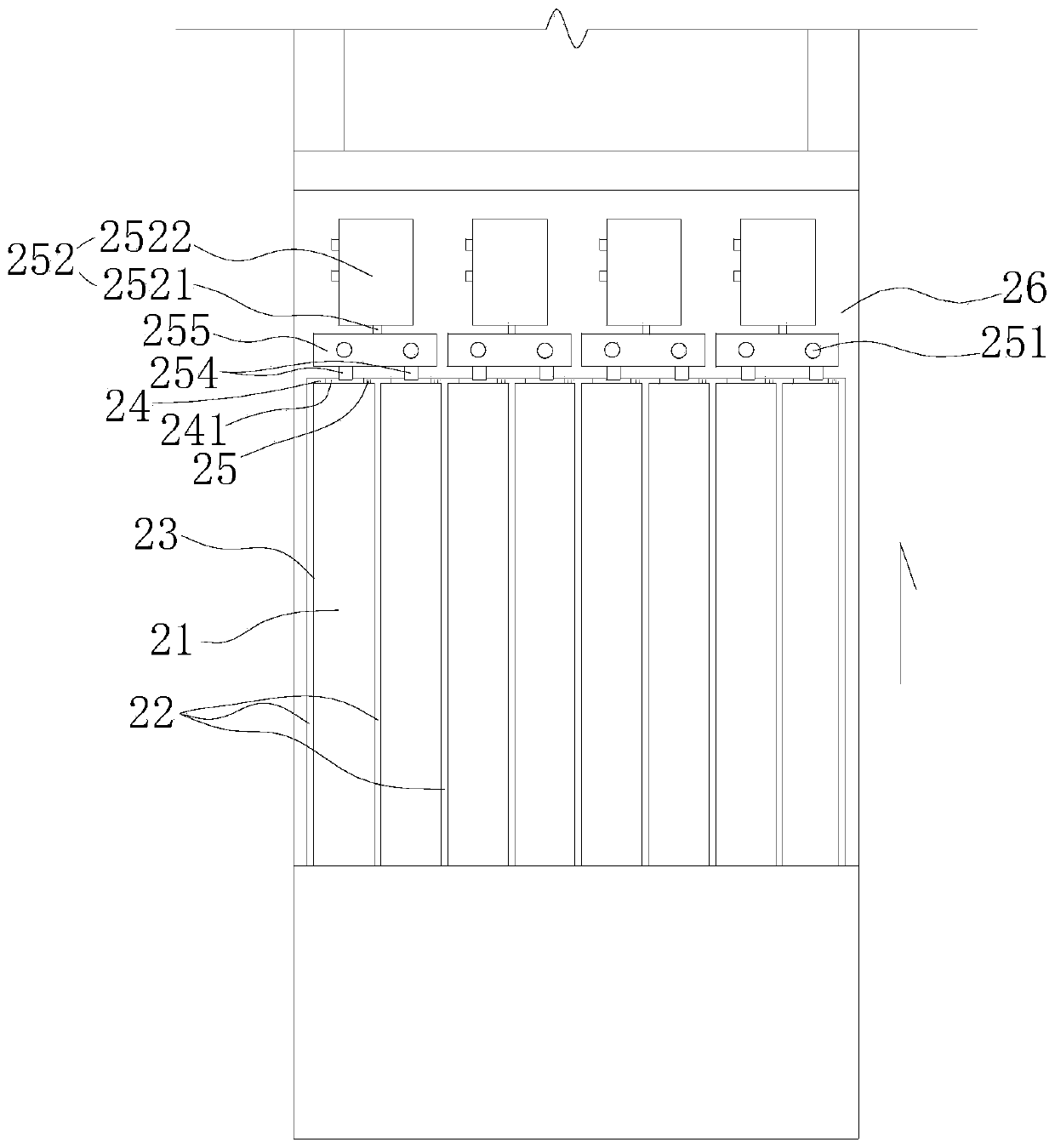

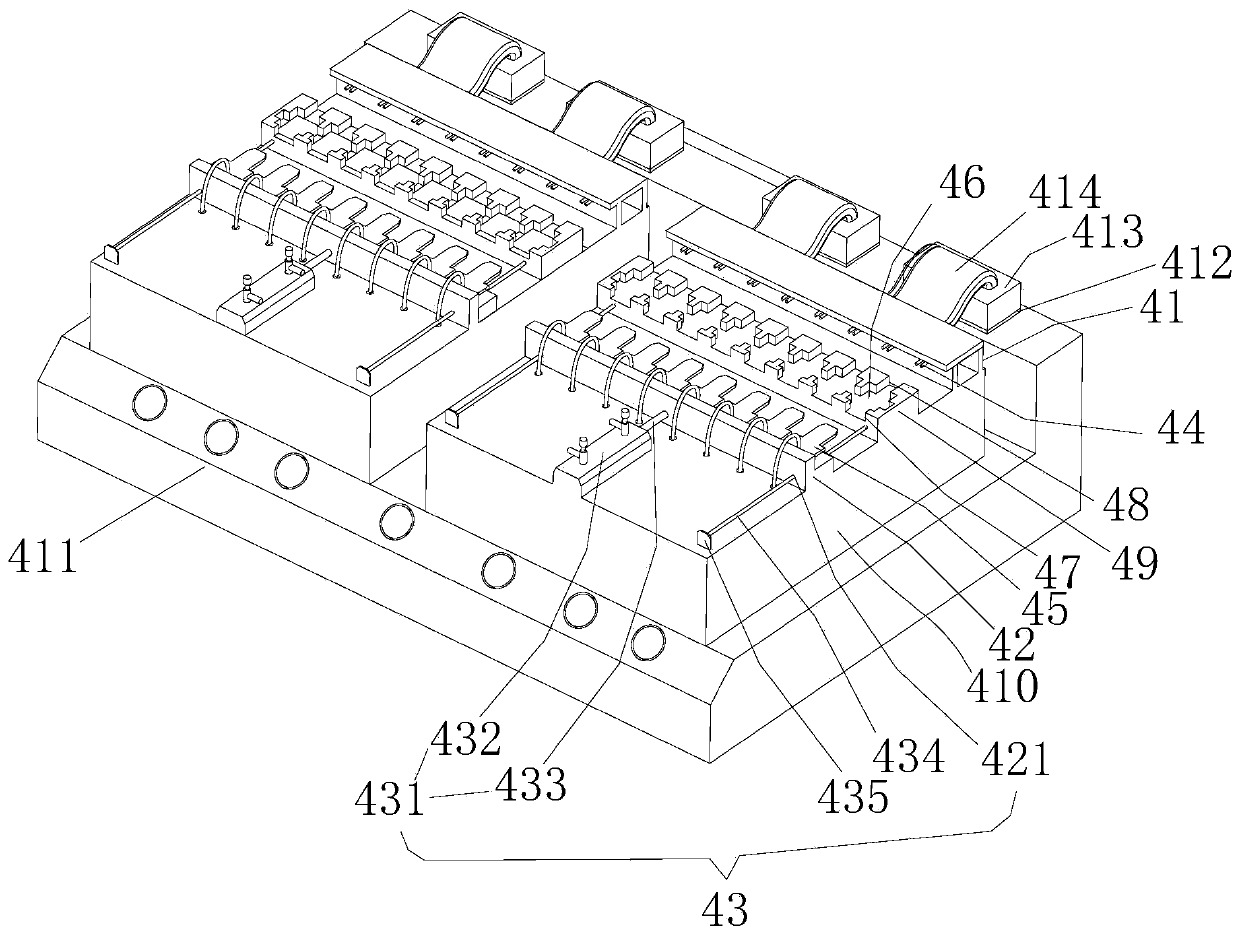

[0029] like figure 1 As shown, the present invention discloses a kind of ATE test equipment with manipulator, and this ATE test equipment comprises the ATE power supply test system 1 for carrying out power supply test, and described ATE power supply test system 1 adopts the prior art for power supply test ATE power supply test system, not to be described in detail here; the ATX test equipment also includes a product delivery mechanism 2, a product shunt delivery mechanism 3, at least one test device 4 for fixing the test product, and a manipulator with a suction cup 5 so that the test product is put into the test device 4 from the product into the delivery mechanism 2 and taken out from the test device 4 and put into the product shunt delivery mechanism 3, the controller 6, the controller 6 is electrically connected with the manipulator 5 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com