Slip formed concrete structure

a technology of slip formed concrete and concrete, applied in the field of slip formed concrete structures, can solve the problems of reducing service life, reducing erosion and abrasion resistance, and affecting the service life of the structure, so as to reduce the service life, eliminate or reduce the irregularities, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

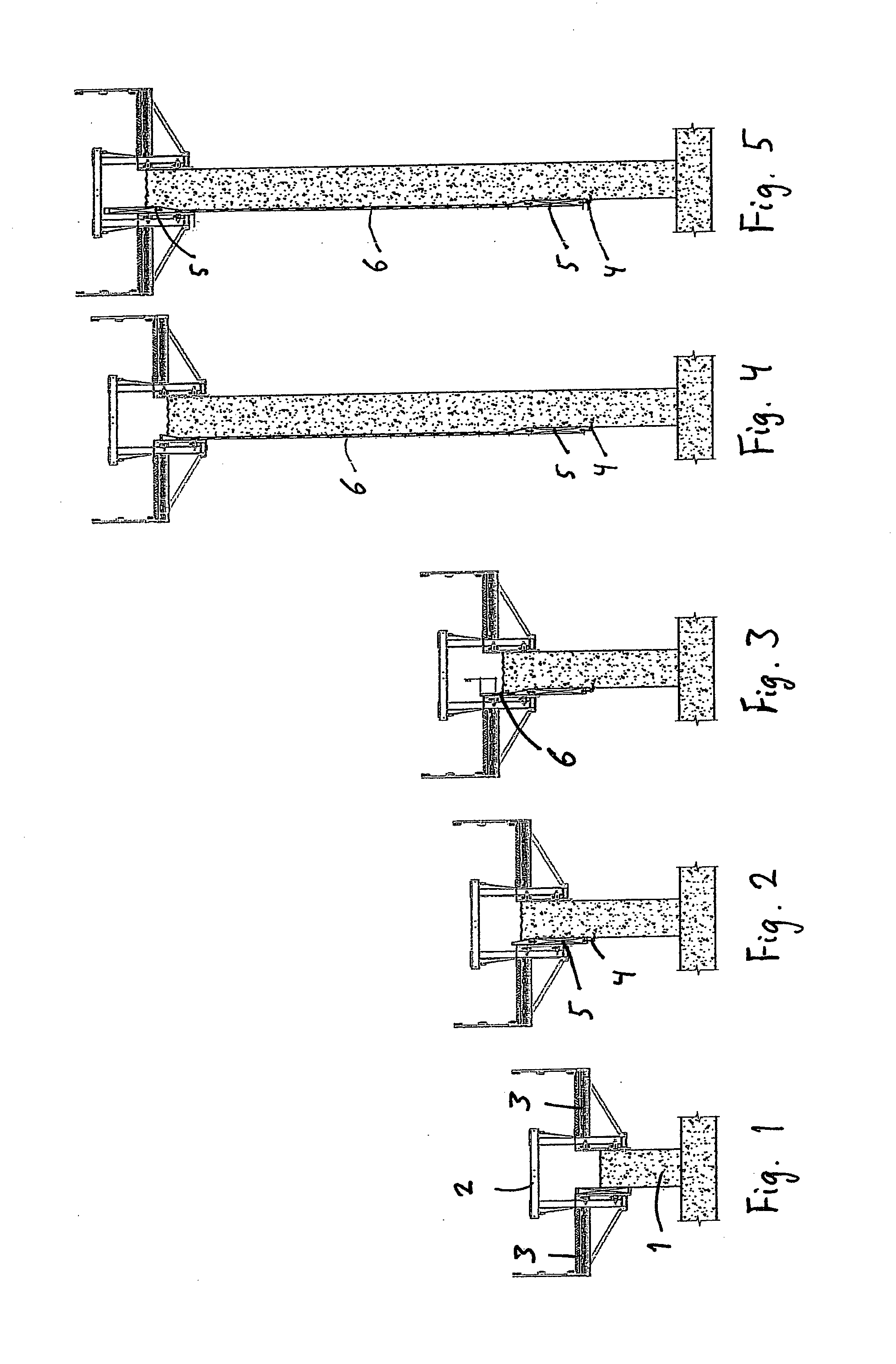

[0017]Reference is made to FIG. 1, illustrating a section through a wall of a gravity base shaft structure 1 that is slip formed and which shall be provided with an abrasion allowance according to the invention. A slip form yoke 2 and working platforms 3 are lifted upwards concurrently as the structure is slip formed upwards, in a conventional way.

[0018]In FIG. 2, a bolted support 4 and an insert form 5 have been arranged on the outer wall of the structure. In FIG. 3 the first panel 6 has been arranged on the insert form 5. The volume inside the panel is filled with concrete of a feasible quality for abrasion resistance and behaviour in the forming operation, which quality may be determined by testing. The armouring is not illustrated. Preferably the steel armouring is not extended into the abrasion allowance, but the abrasion allowance may preferably comprise reinforcing fibres such as steel fibres, carbon fibres, boron fibres or other fibres or ceramics or other material for incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com