Method and device for regulating the production of steam in a steam plant

a technology of steam plant and steam temperature, which is applied in the direction of water supply installation, lighting and heating apparatus, gas/liquid distribution and storage, etc., can solve the problems of difficult to achieve accurate temperature control and greatly influence the temperature to be controlled, and achieve accurate and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

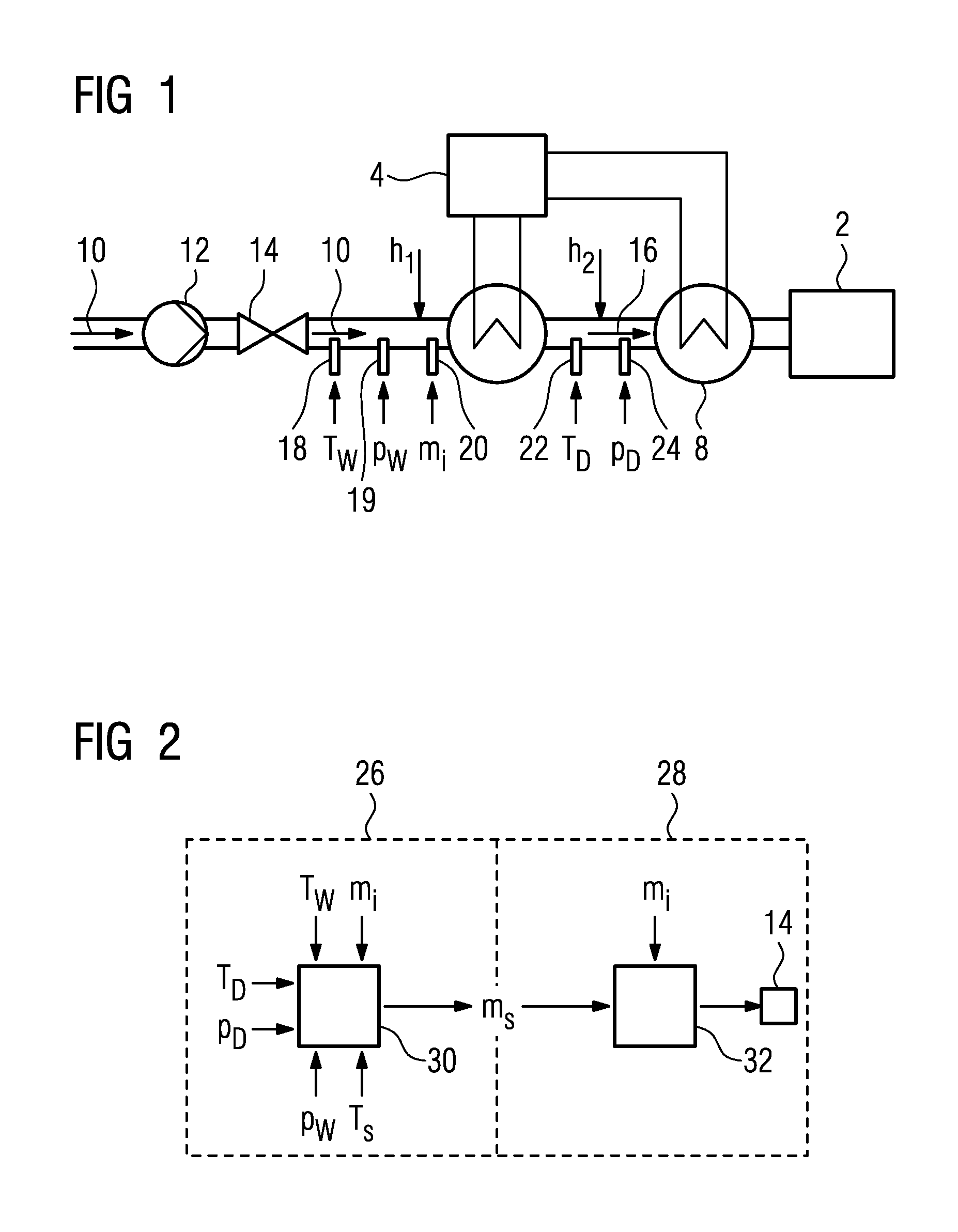

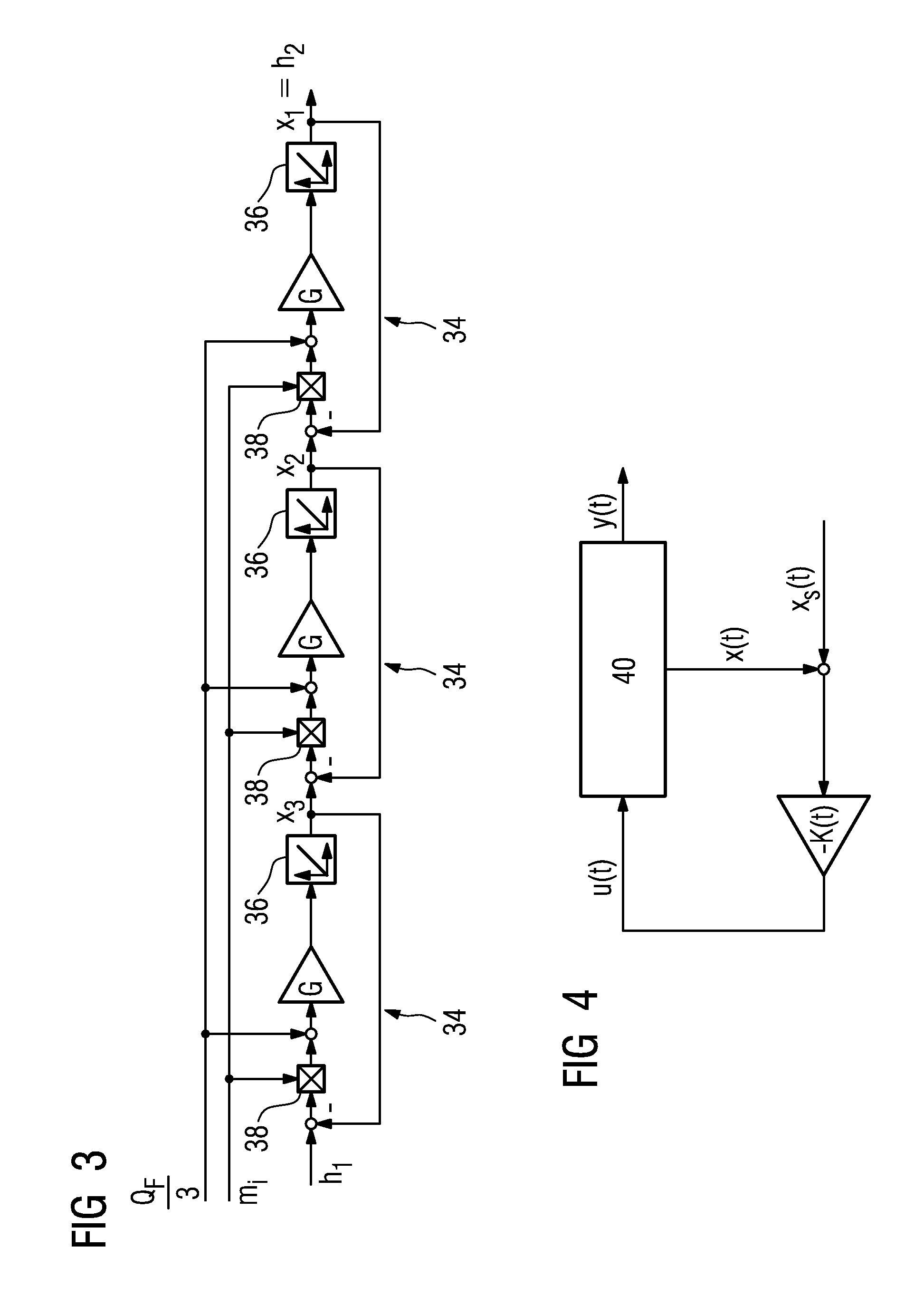

[0033]FIG. 1 shows a schematic view of a detail from a steam power plant with a steam power plant which comprises a steam turbine 2, a boiler 4, and evaporator 6 and a superheater 8. The boiler 4 gives off heat to the evaporator 6, into which flows feed water 10 which is pumped by a feed-water pump 12 to the evaporator 6 and which absorbs the heat. By means of a valve 14, the feed-water flow can be controlled.

[0034]As a result of the absorption of heat, the feed water 10 is evaporated in the evaporator 6, and the resulting steam 16 flows on to the superheater 8 in order to be superheated there to form live steam and then to be fed to the steam turbine 2. For controlling the temperature of the steam 16, the feed-water flow is controlled by means of the valve 14 and / or the feed-water pump 12, wherein a setpoint flow of the feed water 10 upstream of the evaporator 6 is the controlled variable and a valve position and / or a pump output is the manipulated variable.

[0035]A temperature sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com