Polymeric replacement for a glass drinking container

a glass drinking container and polymeric technology, applied in the field of polymeric drinking containers, can solve the problems of reducing the useful life of glass beverage containers, reducing the economic and functional effect of the container, and brittle soda lime glass,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

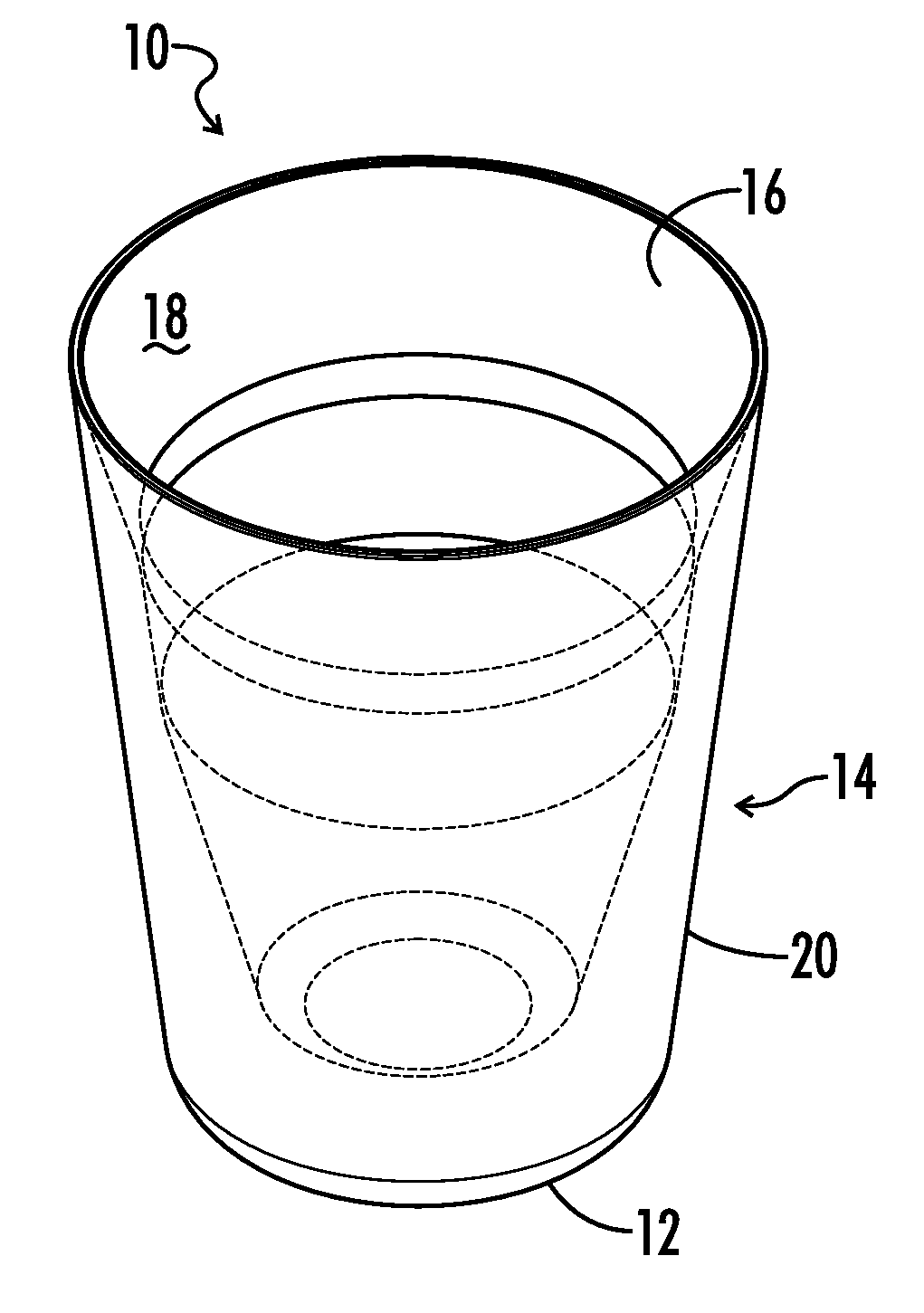

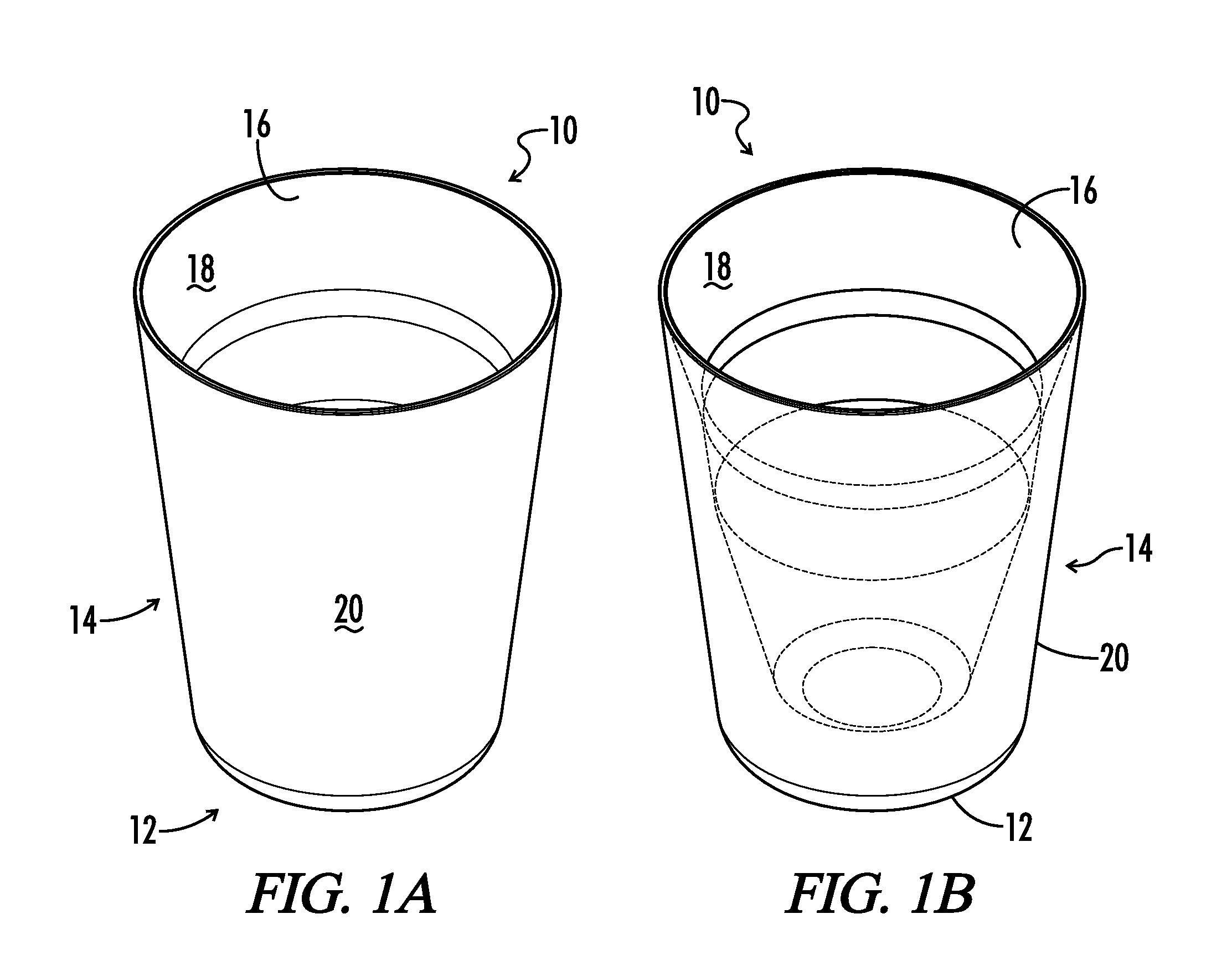

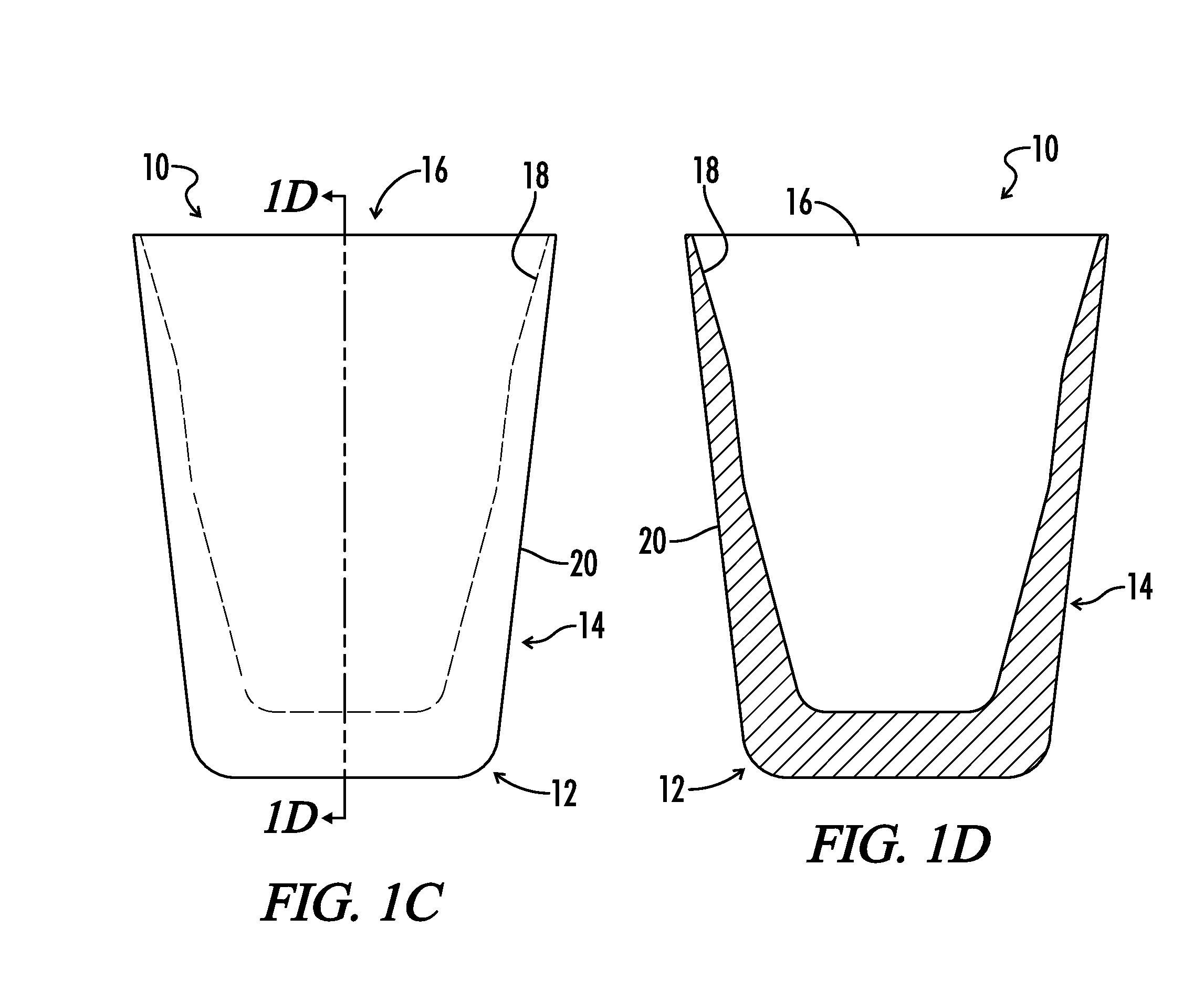

[0055]Referring generally now to the Figures, a polymeric container can be shown and generally illustrated by the numeral 10. The container includes a base 12 and an enclosed wall 14. The enclosed wall 14 can be formed with the base 12 and extends from the base 12 and defines an opening 16, or a mouth 16, opposite the base 12. The wall includes an inside surface 18 and an outside surface 20.

[0056]The polymeric material is preferably a thermoplastic and can be a clear engineering thermoplastic or a filled engineering thermoplastic. For example a clear engineering thermoplastic can include PET, PETG, SAN, PC, TPX, PVC, and the like. The filled engineering thermoplastics can be thermoplastics, such as can be polypropylene, polyethylene, PET, PVC, and the like, filled with additives such as Mica, Calcium Carbonate, Talc, Aluminum Silicate, and the like. Either of these thermoplastics can be the molded compounds used to form the container structures and base. Further, the base can be int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Specific gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com