Hydraulic Fracturing Method

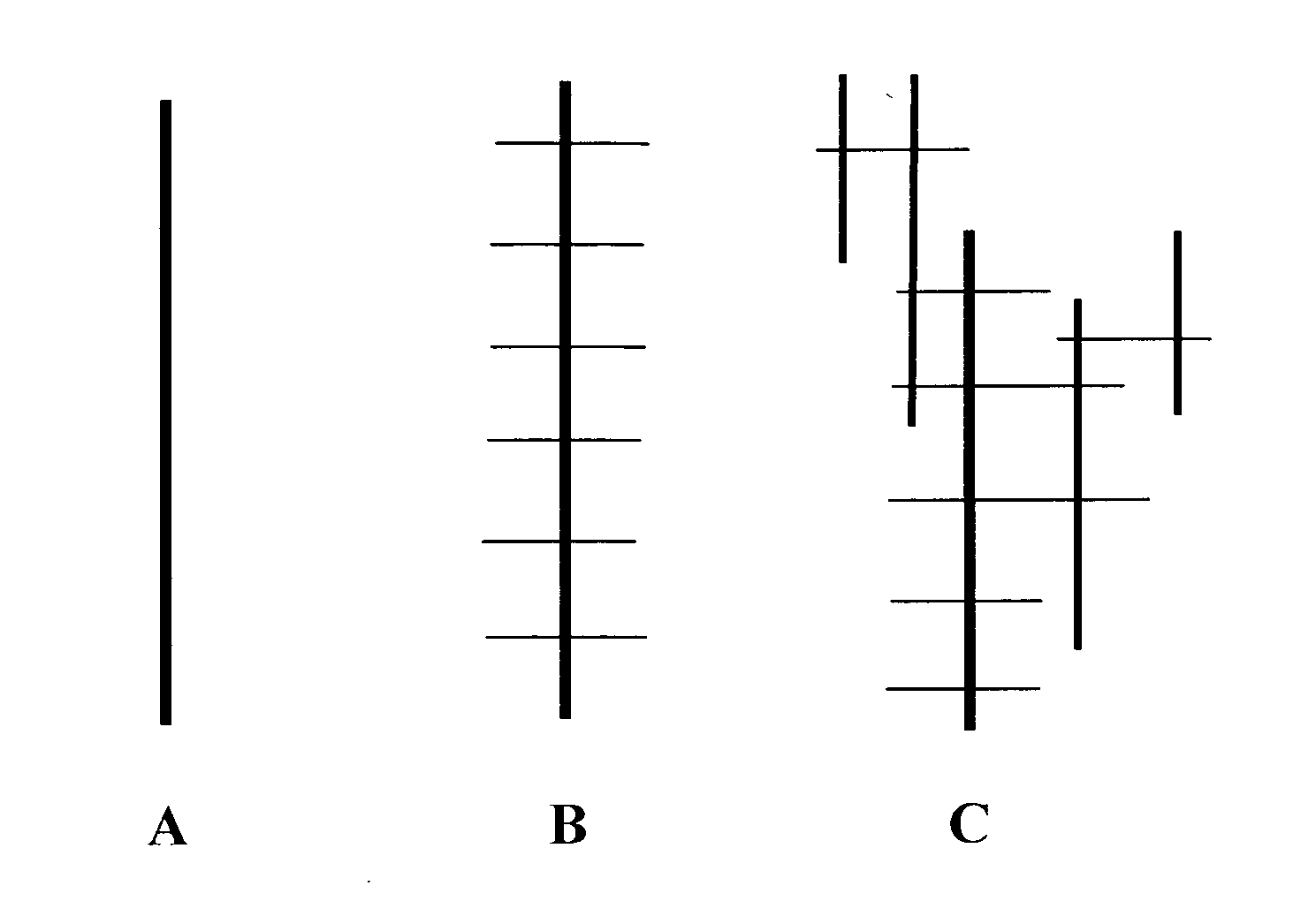

a technology of hydraulic fracturing and fracture network, which is applied in the direction of fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems that existing treatment techniques have not been sufficiently effective for forming fracture networks with high fracture densities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0037]A fluid slug prepared from a borate cross-linked guar gel, having a guar concentration of 6 g / L (50 lb / 1000 gal) was placed in a Plexiglas settling slot with dimensions 1000×300×4 mm, above a slug of similar-density slickwater containing 0.05 weight percent of a polyacrylamide friction reducer. No slug diffusion during the experimental time of 4 hours at room temperature was observed. The viscous slug remained consolidated and floated on the slickwater slug without settling.

example 2

[0038]The behavior of a viscous slug being transported in a long horizontal pipe was studied. A laminar fluid flow regime was tested. These data can be used to evaluate slug transport inside a fracture. In order to investigate slug transport dependencies, a special set-up was constructed. It consisted of a clear plastic water pipe (35 m in length and 18 mm ID), systems for injection of the viscous slug and of a base fluid, a water pump, and two photo sensors (one at the beginning and one at the end of the pipe) to determine the length of the viscous slug, and a data acquisition system. A special loop was used for injection of slugs of the viscous fluid. A viscous slug of a desired composition was loaded into the slug injection loop before the experiment and was isolated from the main line by valves. Base fluid was pumped through the pipe for several minutes until the base fluid flow stabilized. Once flow stabilization was attained, the flow was directed into the slug sample injectio...

example 3

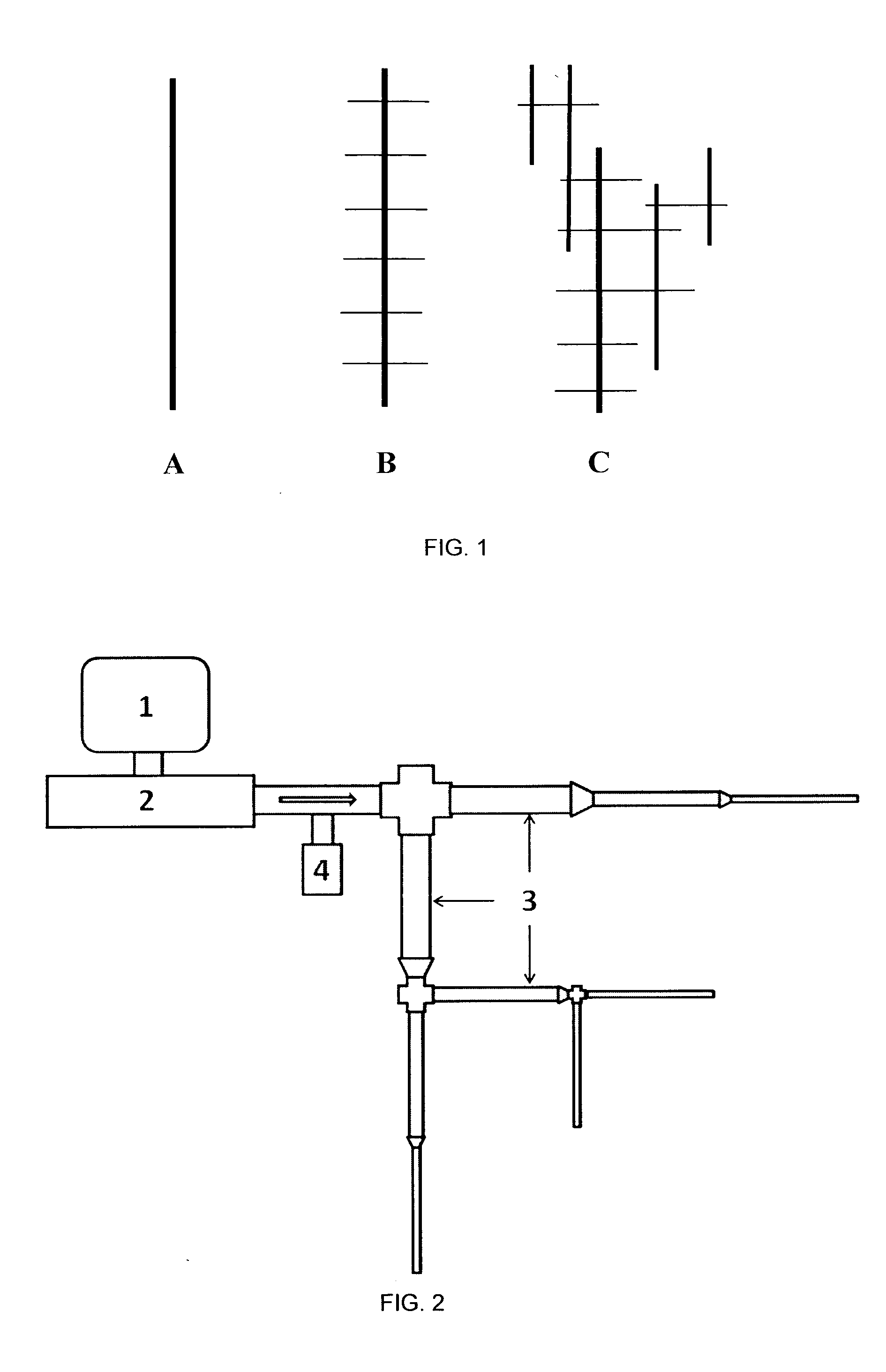

[0040]A manifold [3] as shown in FIG. 2 was built using Swagelok tubes with outer diameters varying from 6.35 mm (0.25 in) down to 1.59 mm ( 1 / 16 in). FIG. 3 shows the test results in which the pressure inside the tube was plotted against time. The same slickwater as used in Examples 1 and 2 was pumped through the manifold with a Knauer pump [1] at 0.5 l / min flow rate with pressures generally not exceeding 138 kPa (20 psi). Slugs of the crosslinked gel used in Examples 1 and 2 were then placed in the slurry tank [2] and the pressure was followed during pumping; the pressure increased up to 1007 kPa (146 psi), at which pressure the pressure relief rapture disk [4] broke. The manifold system emulates a complex fracture network during the diversion stage, and the rupture disk break mimics fracturing of a non-stimulated zone of the reservoir due to the net pressure increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com