Forced Insertion Concentric Ground-Coupled Heat Exchanger for Ground Source Heat Pumps

a heat exchanger and concentric ground technology, applied in geothermal energy generation, heat production devices, light and heating equipment, etc., can solve the problems of poor heat transfer capability when compared to metals, and achieve the effect of short installation time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Heat Exchanger Design:

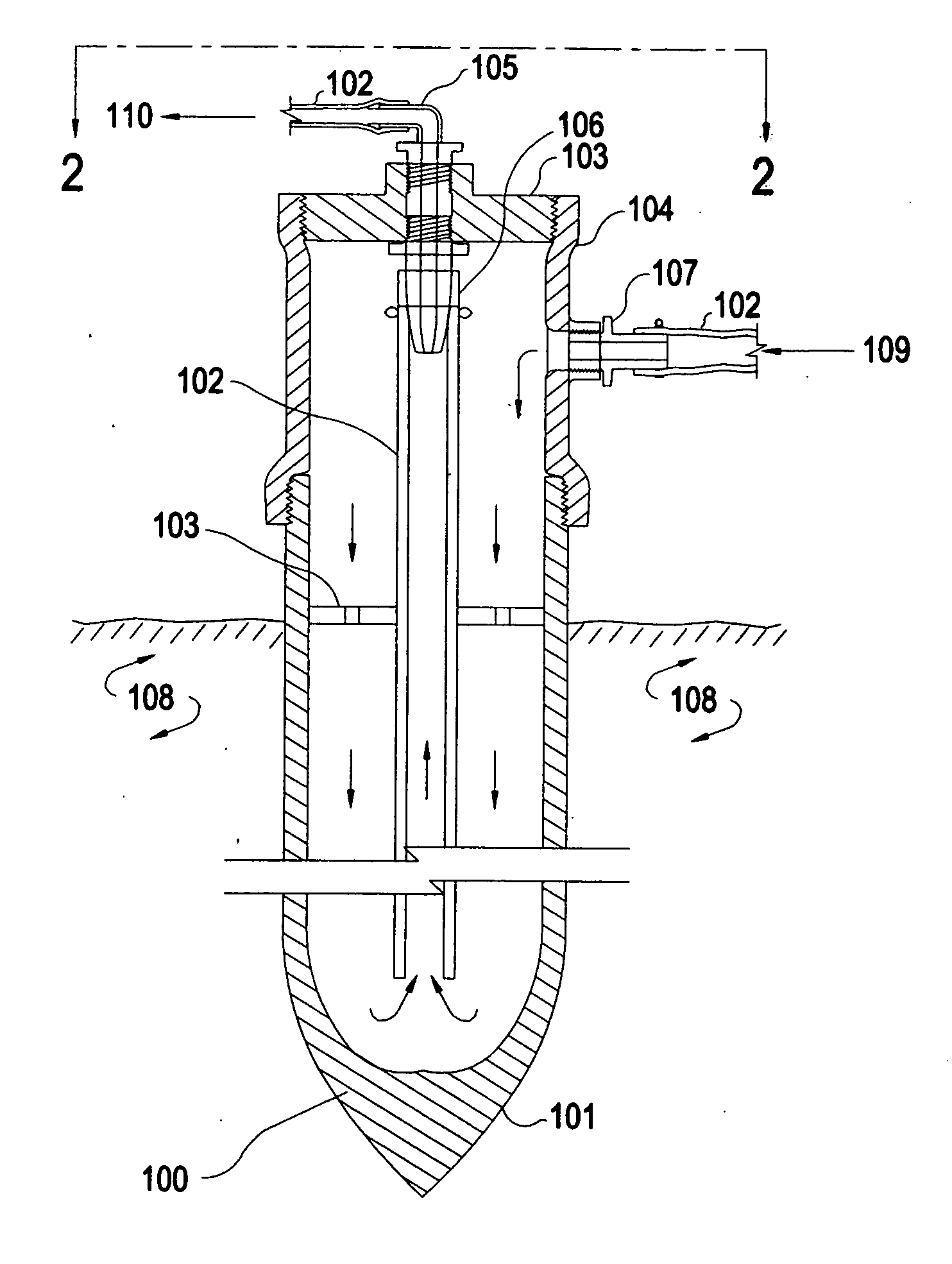

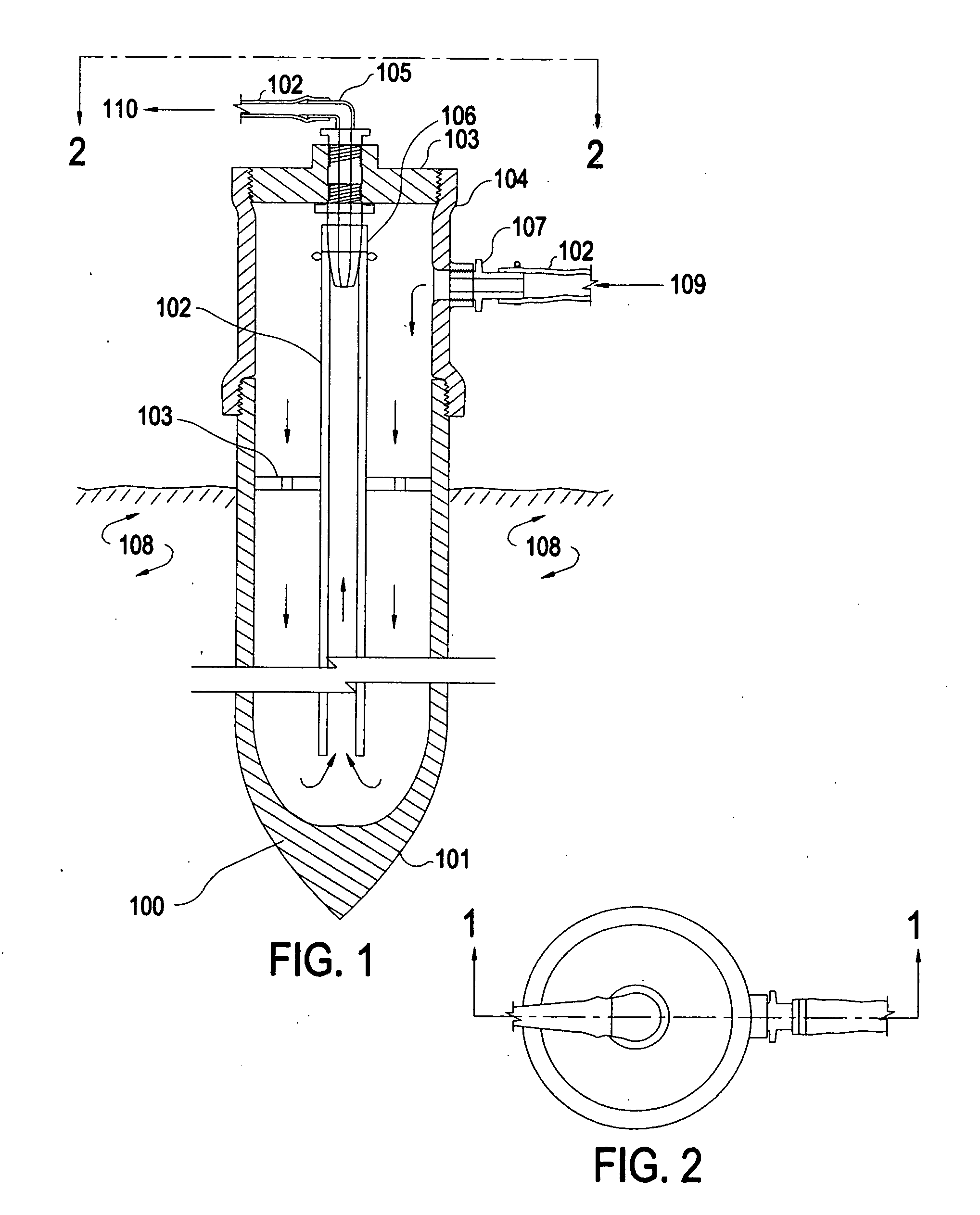

[0027]The concentric tube ground source heat exchangers have been known as prior art for many years [Oliver, J., and H. Braud, 1981. Thermal exchange to earth with concentric well pipes. Transactions of ASAE. 24(4): 906-910]. Notes the use of concentric pipe Heat exchangers]. Also, in patent application Ser. No. 12 / 720052 by Lawless et al, the use of concentric Heat exchangers is noted. The specific designs for existing concentric Heat exchangers utilize complicated ribbed tubes and special head plumbing. Today's invention provides a much-simplified design, consisting of standard piping, tubing, and fittings (100). The invention provides a novel and inexpensive method of installing the inner concentric flow tube (106) into the pointed 20 to 40 foot long heat exchange pipe (101) by using standard materials arranged in a novel fashion to accomplish the objective. The novel means to provide the concentric annular flow is shown in FIG. 1 and encompasses the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com