Inkjet printer having printhead and ink for minimizing corrosion of exposed corrodible structures within printhead

a technology of inkjet printers and printheads, applied in the field of inkjet inks, can solve the problems of significant reduction in print quality, unacceptable degree of roof delamination, and corrosion of silicon oxide, and achieve the effect of minimizing corrosion of corrodible surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

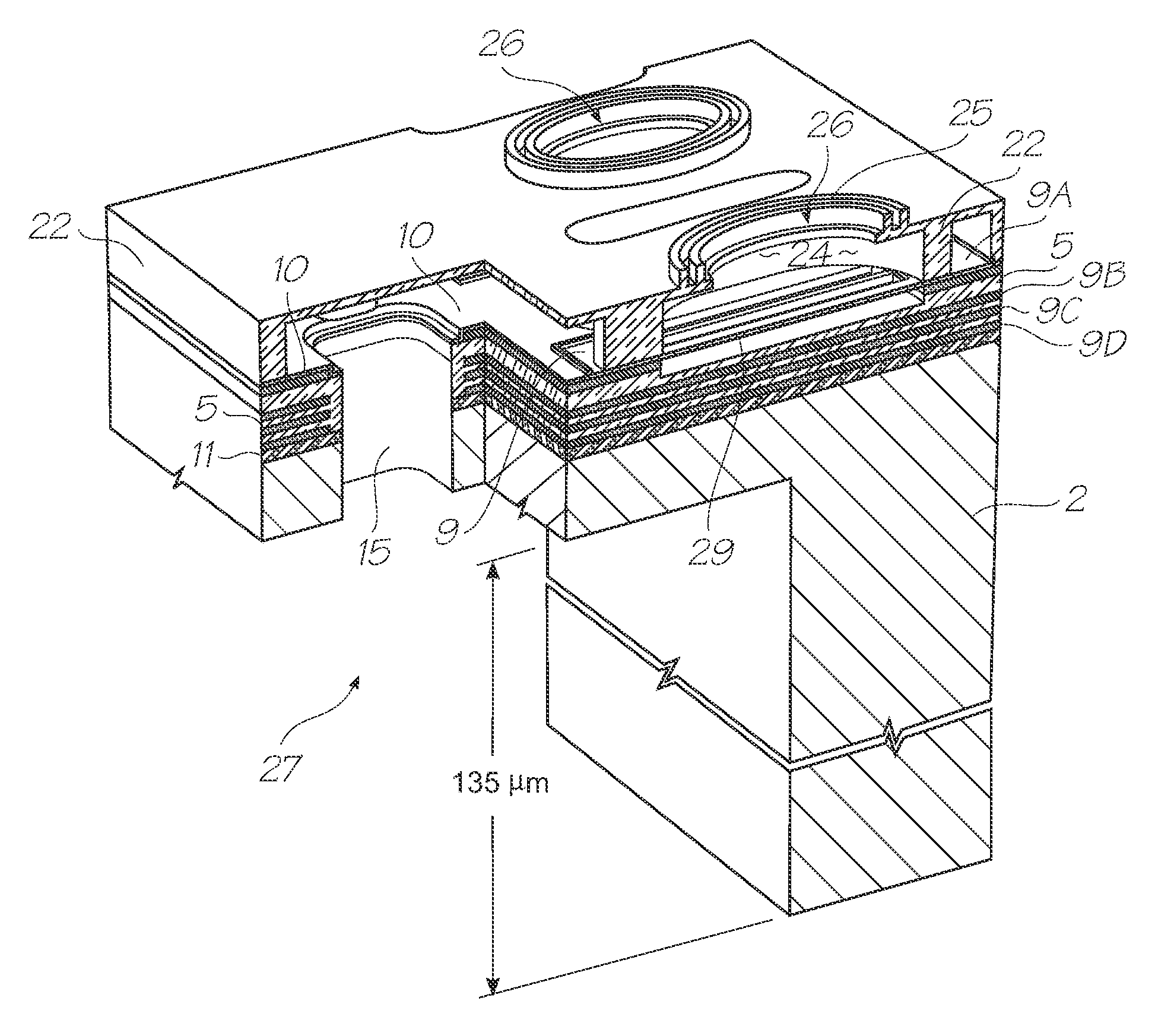

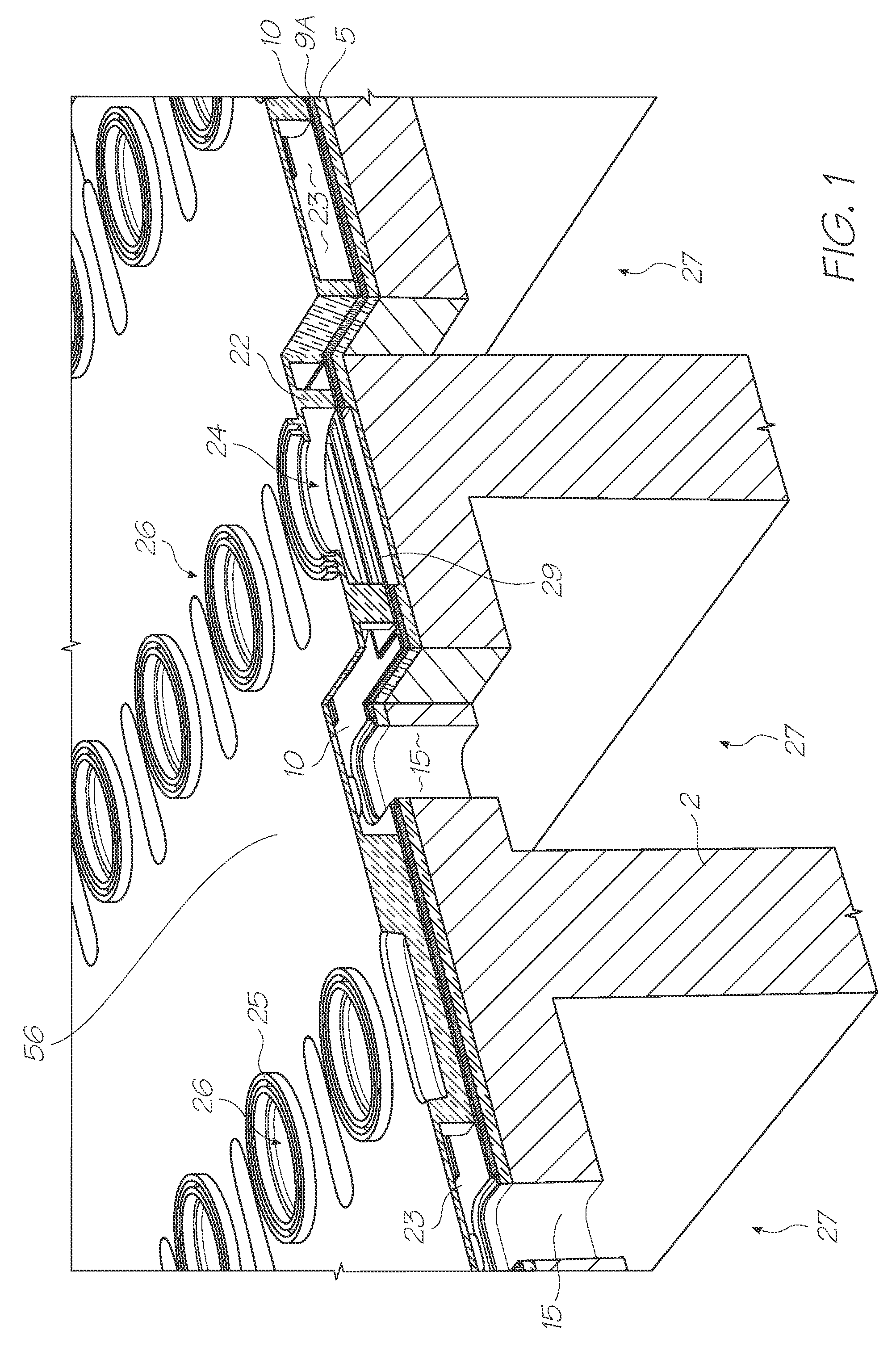

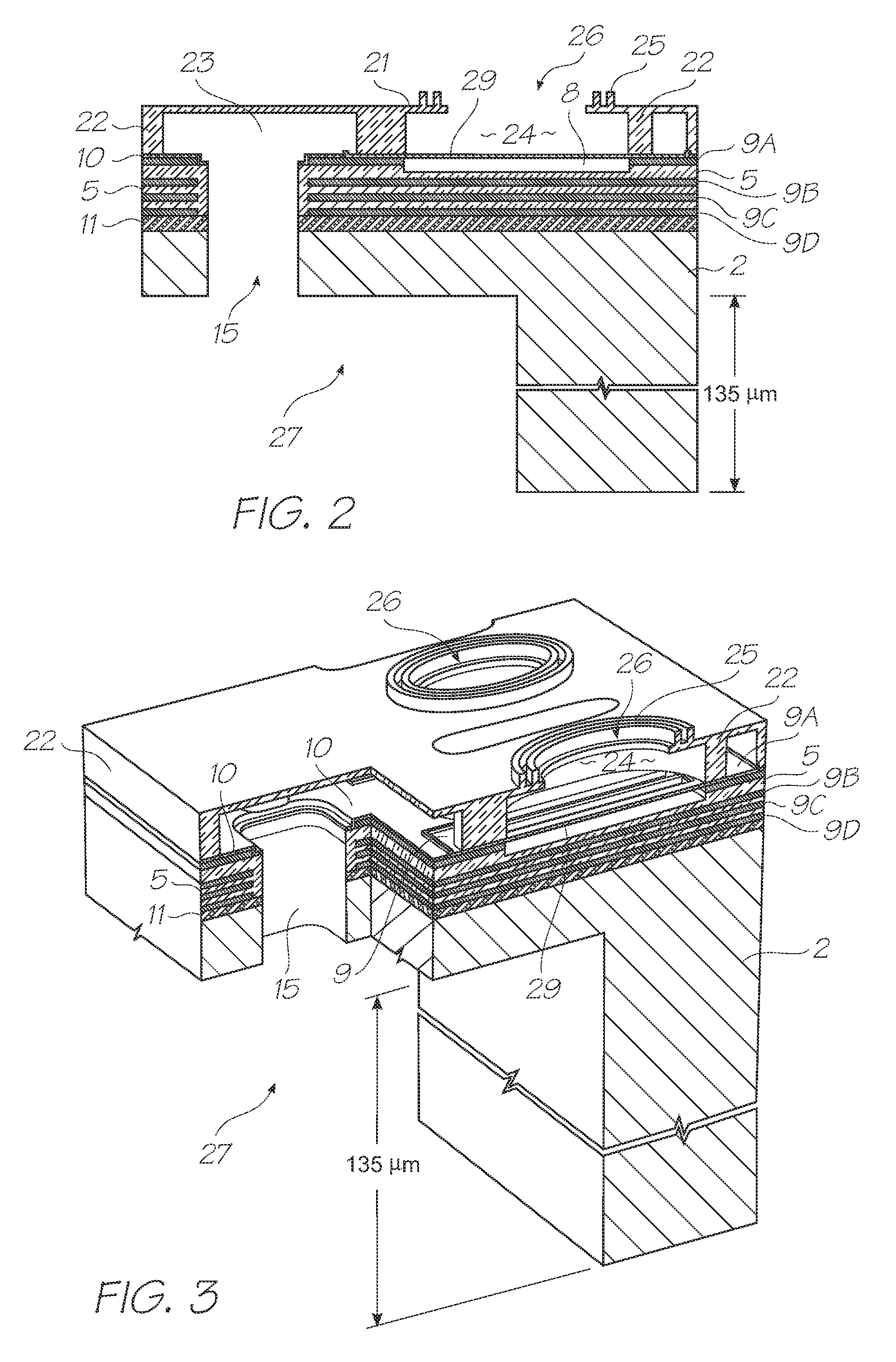

[0105]As foreshadowed above, the present invention minimizes corrosion of corrodible structures in inkjet printheads which are exposed to certain dye-based inks. The corrodible structures are typically silicon nitride, BPSG and, to a lesser extent, silicon oxide.

[0106]Initially, the present Applicant observed print defects in certain color channels of its inkjet printheads, most noticeably in black color channels. Forensic examination of such printheads using SEM microscopy revealed that a degree of roof delamination was occurring and it was posited that the dye-based ink was responsible for corroding silicon nitride structures in the nozzle chamber. Significantly, in printheads having a bilayered roof (an upper layer of silicon oxide and a lower layer of silicon nitride), the corrosion was most evident in the silicon nitride layer. Silicon surfaces in the printhead were observed to be resistant to corrosion by the dye-based inks.

[0107]Following these observ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com