Cooling device with controllable evaporation temperature

a cooling device and controllable technology, applied in the field of cooling devices, can solve the problems of complex logistics for the provision or generation and storage of liquefied gases, the inability to adjust the throttle, and the resultant very cold temperature of the adjustable throttle, so as to achieve simple and yet effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

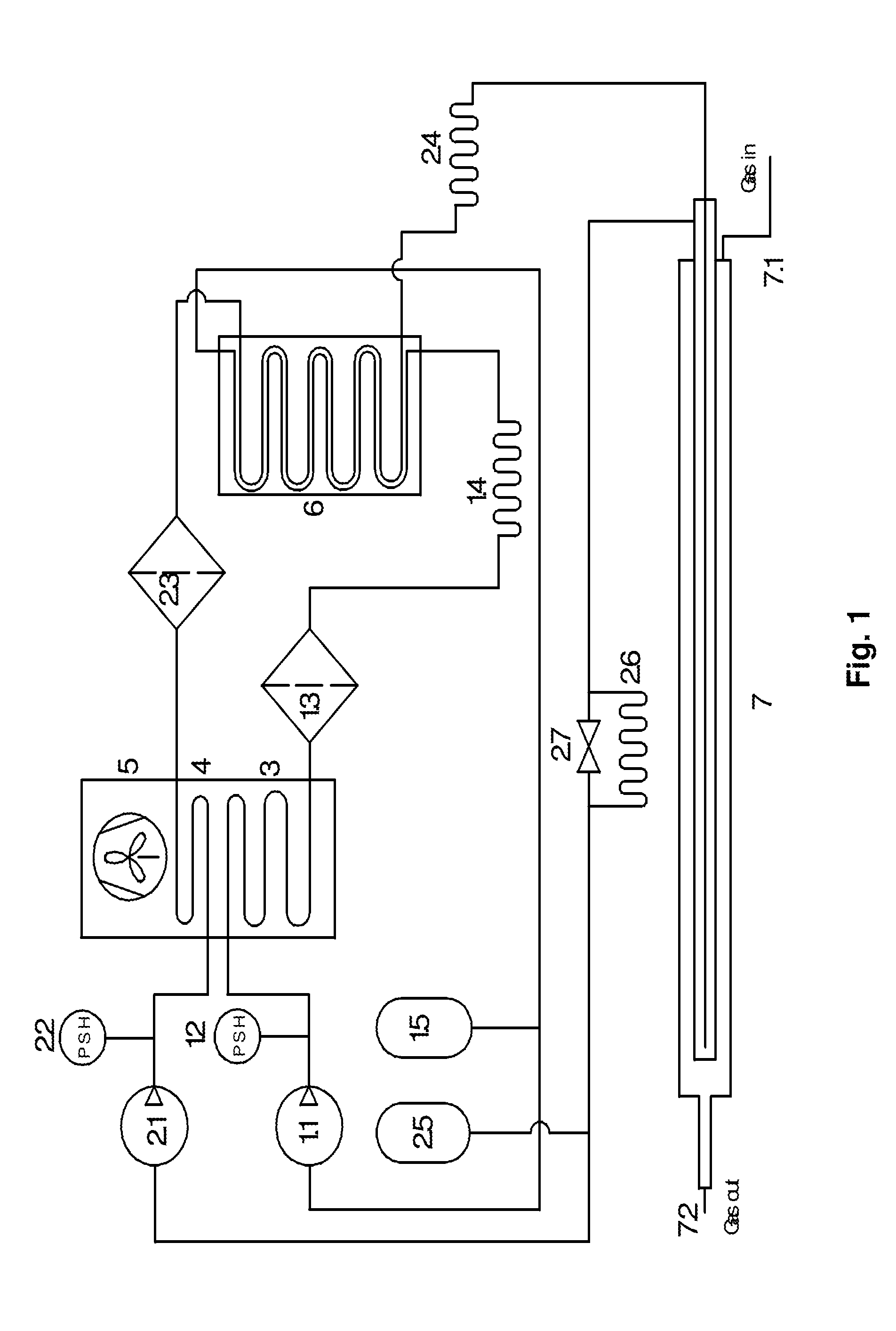

[0022]The cooling device shown by way of example in FIG. 1 includes a first cascade cooling stage with compressor 1.1, safety pressure switch 1.2, filter 1.3, relief throttle 1.4, and pressure compensating vessel 1.5 as well as a second cascade cooling stage with compressor 2.1, safety pressure switch 2.2, filter 2.3, relief throttle 2.4, and pressure compensating vessel 2.5.

[0023]A combined air heat exchanger with fan 5 is e.g. used as liquefier 3 for the first cascade cooling stage and as desuperheater 4 for the second cascade cooling stage.

[0024]A heat exchanger 6 is used as evaporator for the first cascade cooling stage and as liquefier for the second cascade cooling stage.

[0025]An evaporator (heat exchanger) 7, illustrated by way of example as transfer line of the cooling gas, is used as evaporator for the second cascade cooling stage to provide the desired cooling power in that the gas to be cooled is guided from the inlet 7.1 to the outlet 7.2.

[0026]In accordance with the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com