Special drive system that provides automatic application control of granular material

a technology of automatic application control and drive system, which is applied in the direction of centrifugal wheel fertilisers, ways, constructions, etc., can solve the problems of not having a continuous control of the distribution rate of manure, and no solution to all problems, so as to achieve efficient and inexpensive control, the effect of simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

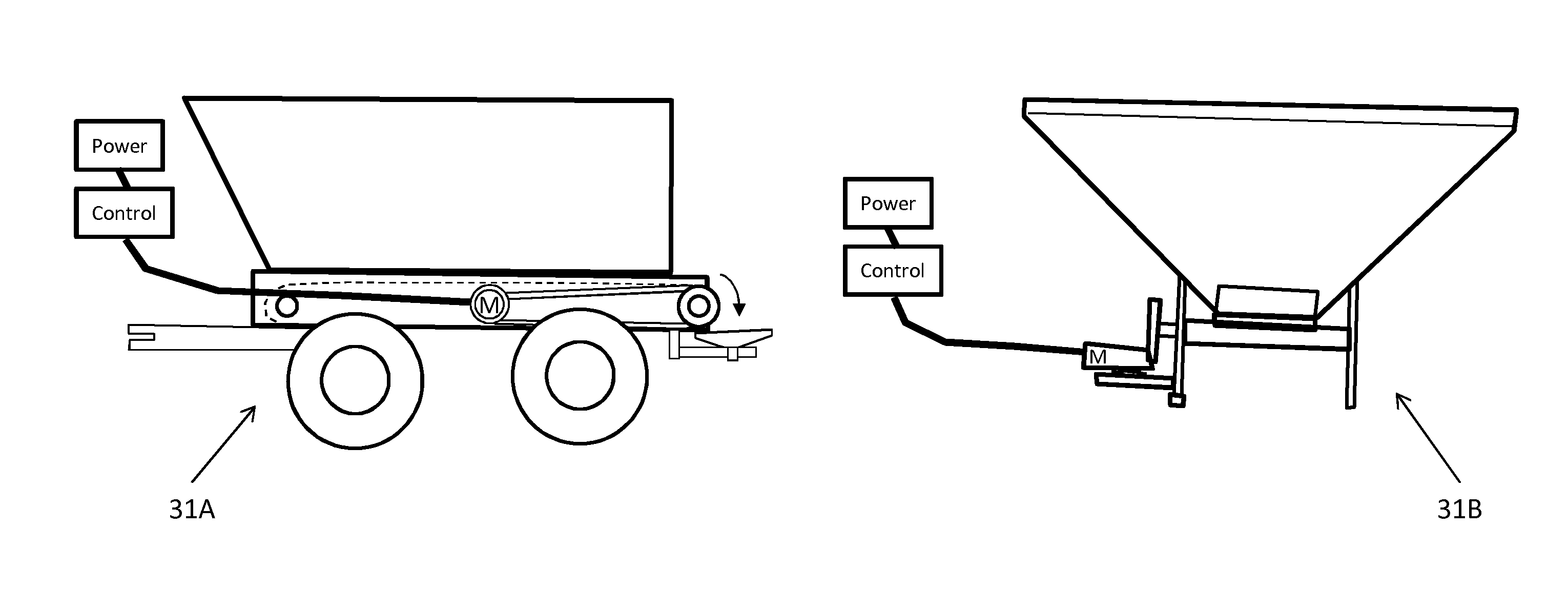

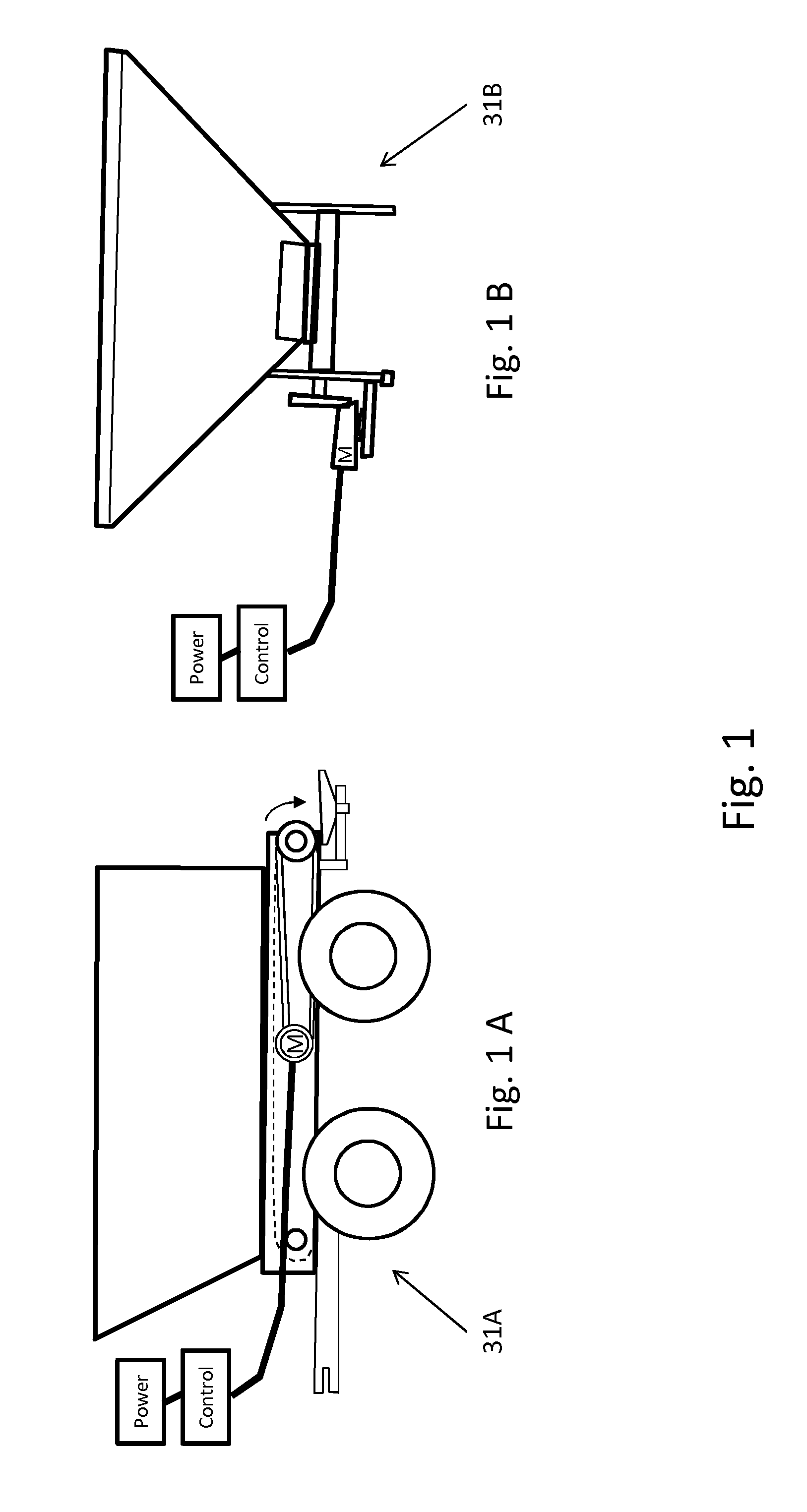

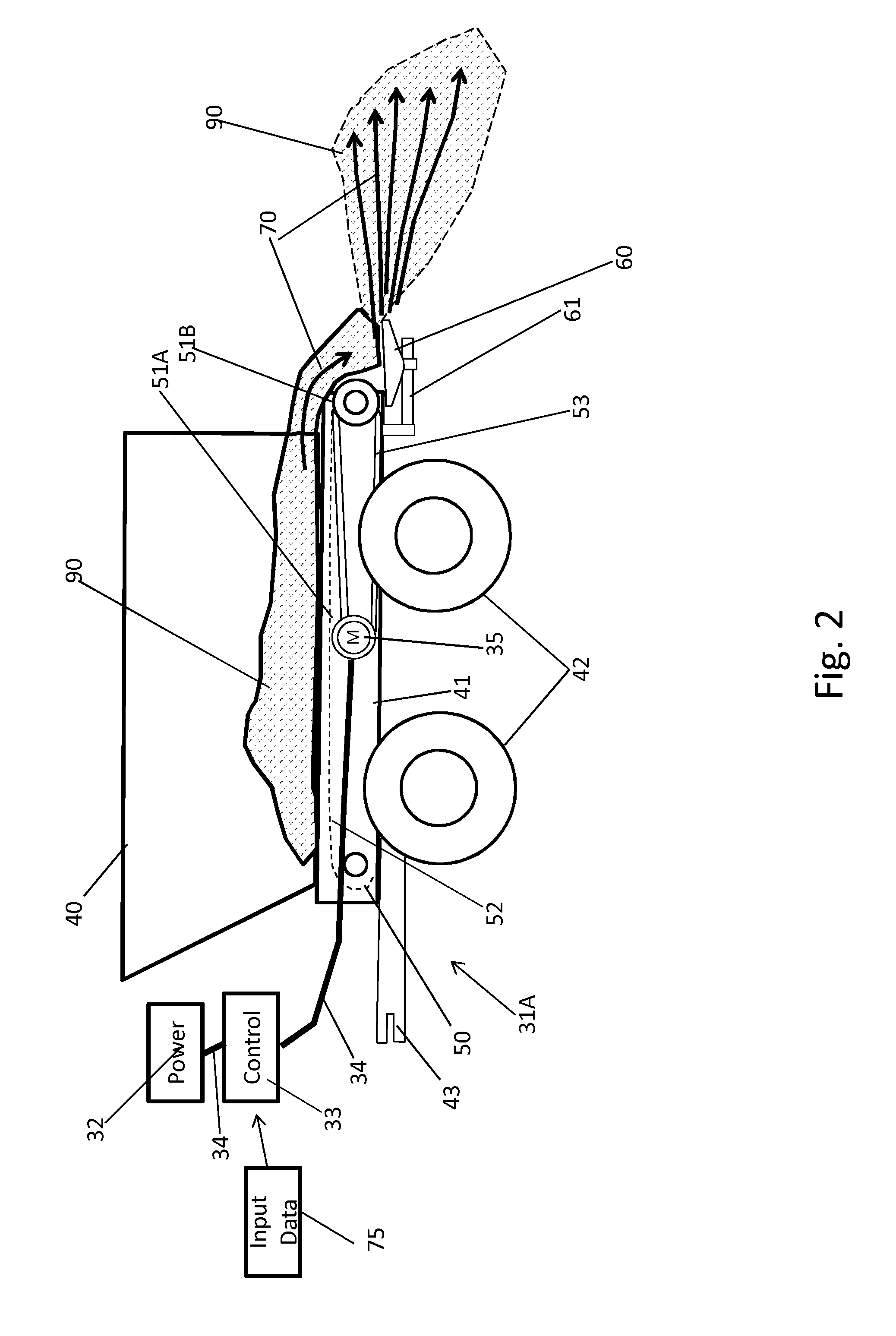

[0049]The present development relates to a special drive system that provides automatic application control of granular materials. Particularly this system and device are related to dispensing of any type of granular material including but not limited to fertilizer, lime, seed, highway road salt, sand, and other broadcasted granular materials. These materials are currently dispensed by a system with less accurate means (mechanical ground wheels) or by a system considerably more complex and more expensive (hydraulic means).

[0050]Being taught here are the ways a special drive system that provides automatic application control of granular materials may be attached to a new or retro-fitted to an existing hopper for dispensing granular materials. Therefore, this may be as an original equipment option or an add-on system sold in the equipment aftermarket.

[0051]The advantages for a special drive system that provides automatic application control of granular materials are listed above in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com