Rotary vane compressor

a compressor and rotary vane technology, applied in machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of increasing assembly man-hours and thereby their costs, complex working processes of the vanes, and coil spring application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

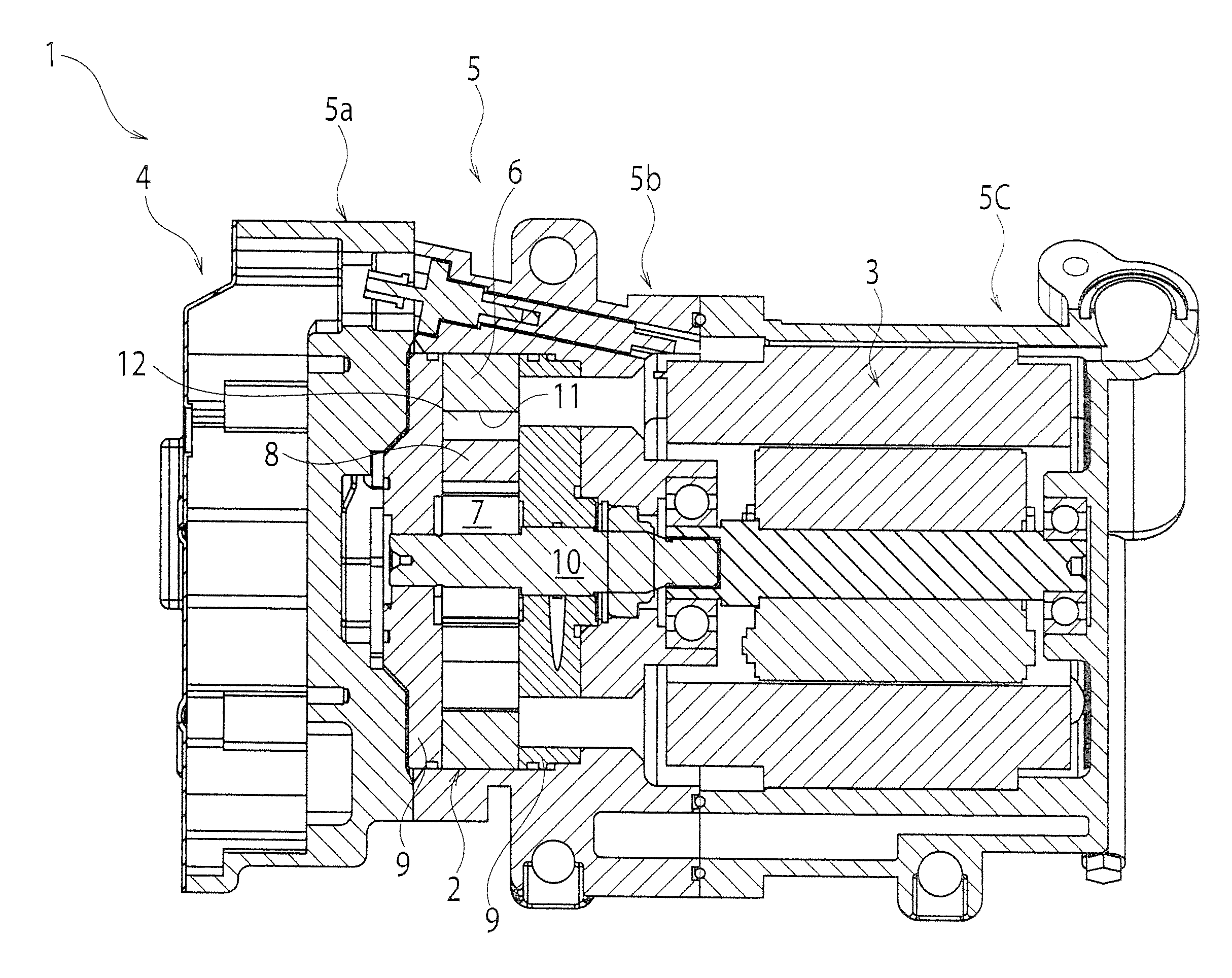

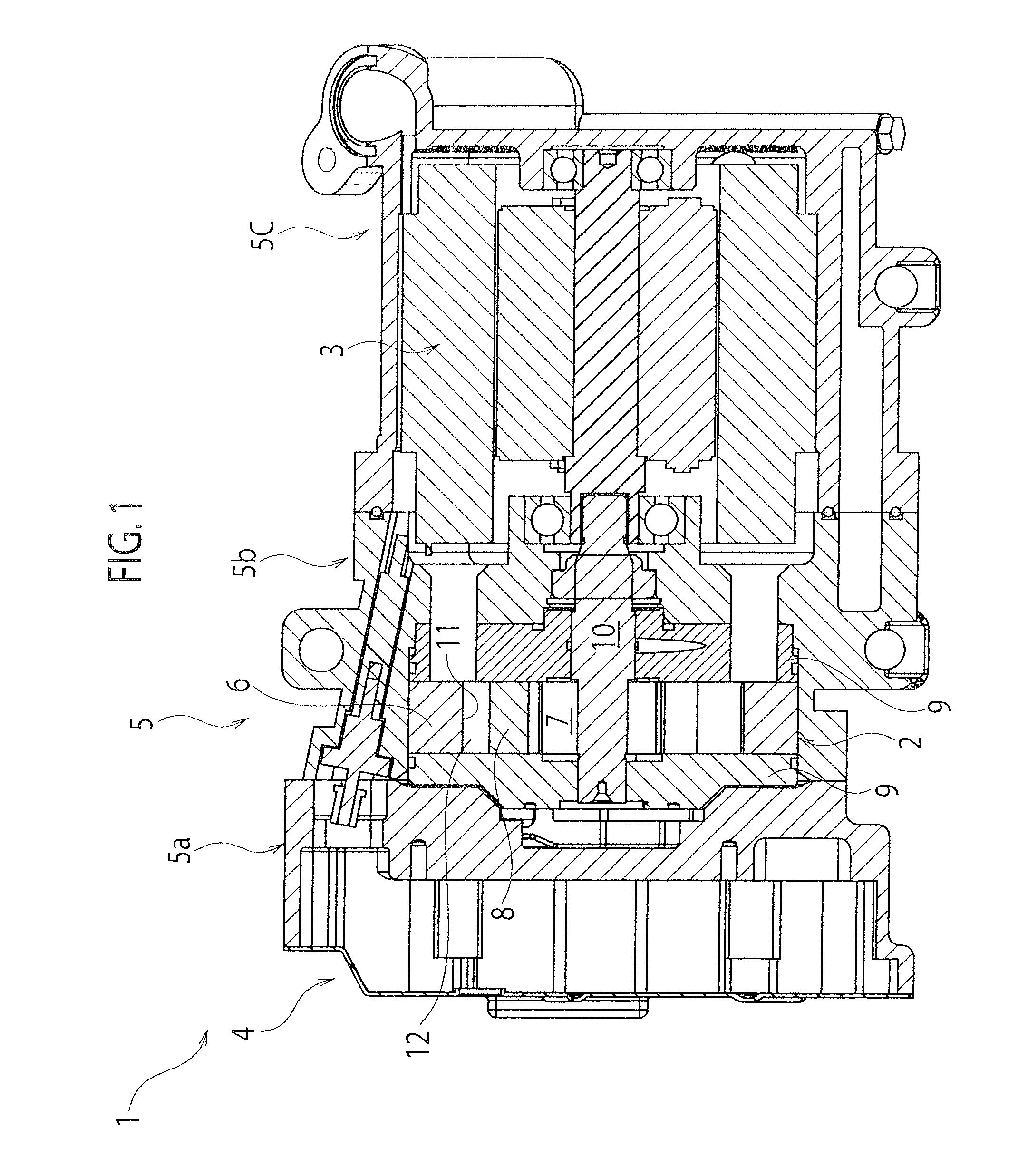

[0022]As shown in FIGS. 1 and 4, a rotary vane compressor 1 according to the present embodiment includes, as its main components, a compression mechanism 2, electrical motor 3, an inverter 4, and a controller 15 for controlling the electrical motor 3 via the inverter 4. A housing 5 of the compressor 1 is comprised of a front housing 5a, a middle housing 5b and a rear housing 5c. An internal space sealed in the inside of the housing 5 by coupling these housings 5a to 5c with each other, and the compression mechanism 2 and the electrical motor 3 are housed in the internal space. The internal space is segmented by the compression mechanism 2, so that a suction chamber for refrigerant is provided on one side of the compression mechanism 2 (on a left side in FIG. 1) and a discharge chamber for refrigerant is provided on another side (on a right side in FIG. 1). The electrical motor 3 is provided in the discharge chamber for refrigerant.

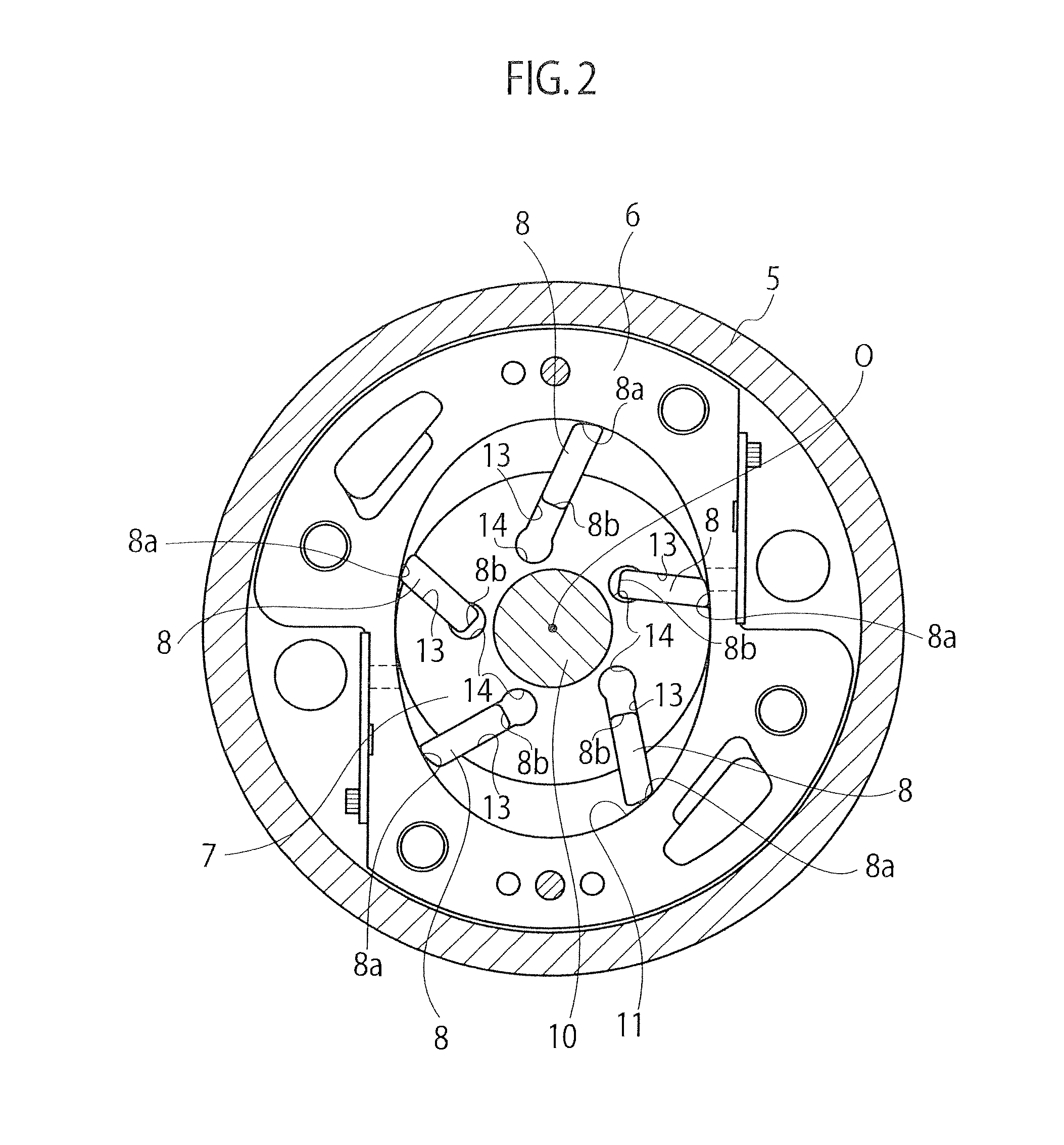

[0023]As shown in FIG. 2, the compression mechanism ...

second embodiment

[0035]Next, a compressor 1 according to a second embodiment will be explained with reference to FIG. 6.

[0036]In the above-explained first embodiment, the controller 15 controls the electrical motor 3 as a drive source of the compression mechanism 2 to normally / reversely rotate the rotor 7. In the present embodiment, the controller 15 controls a gear mechanism 31 to normally / reversely rotate the rotor 7.

[0037]As shown in FIG. 6, the gear mechanism 31 includes a normal rotation rotary shaft 32 and a reverse rotation rotary shaft 33 that are rotated by a rotational drive force form a drive source 30, a normal rotation gear set 34 provided on the normal rotation rotary shaft 32, and a reverse rotation gear set 35 provided on the reverse rotation rotary shaft 33.

[0038]The normal rotation gear set 34 has a normal rotation first gear 34a and a normal rotation second gear 34b, and coupled with the compression mechanism 2 via these gears 34a and 34b. The reverse rotation gear set 35 has a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com