Reaction vessel and method for the handling thereof

a reaction vessel and reaction technology, applied in the field of new type of reaction vessels, can solve the problems of not being particularly robust in structure nor operation, laborious cleaning of cuvettes between tests, prior art, etc., and achieve the effect of reducing costs for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

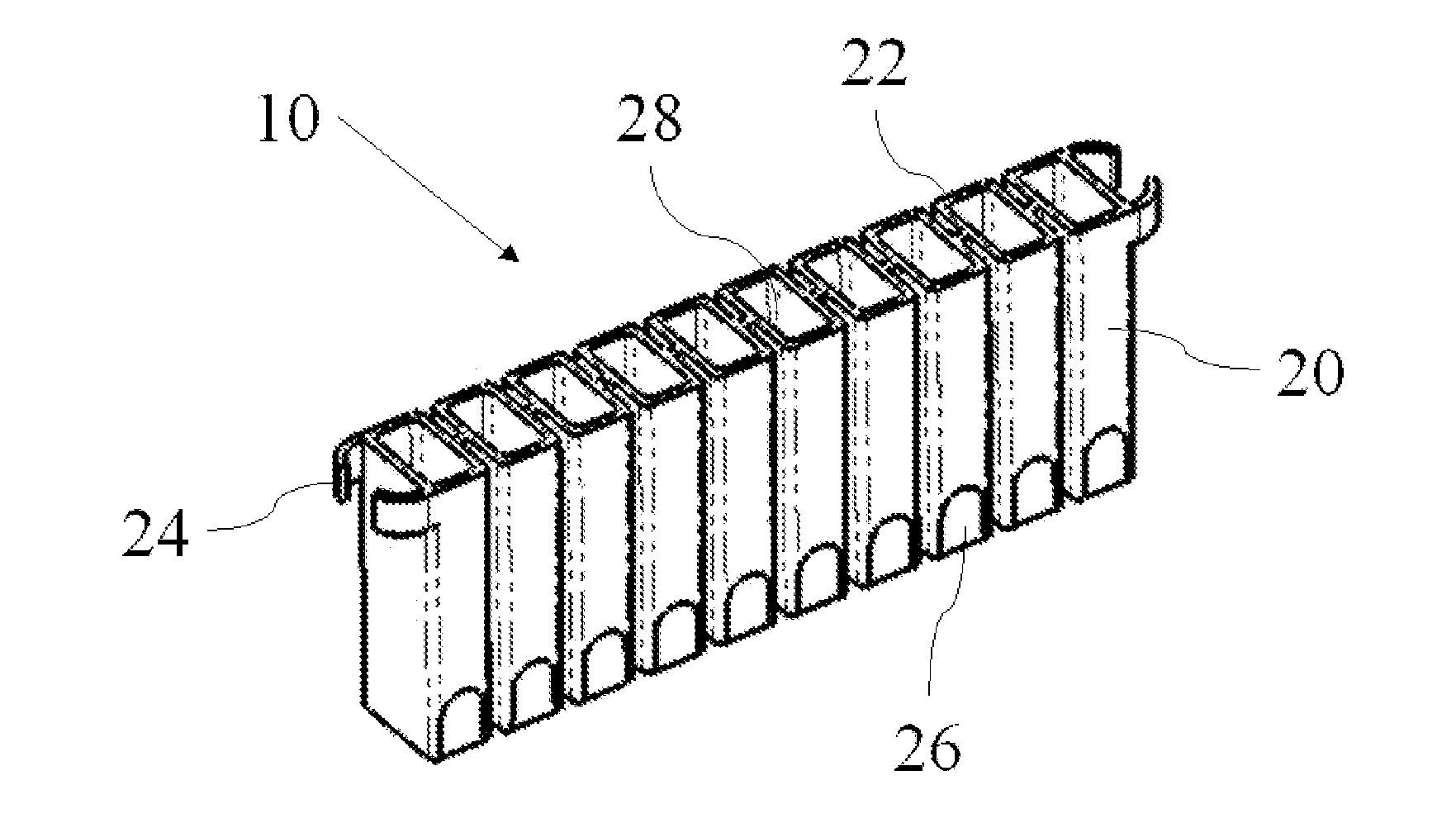

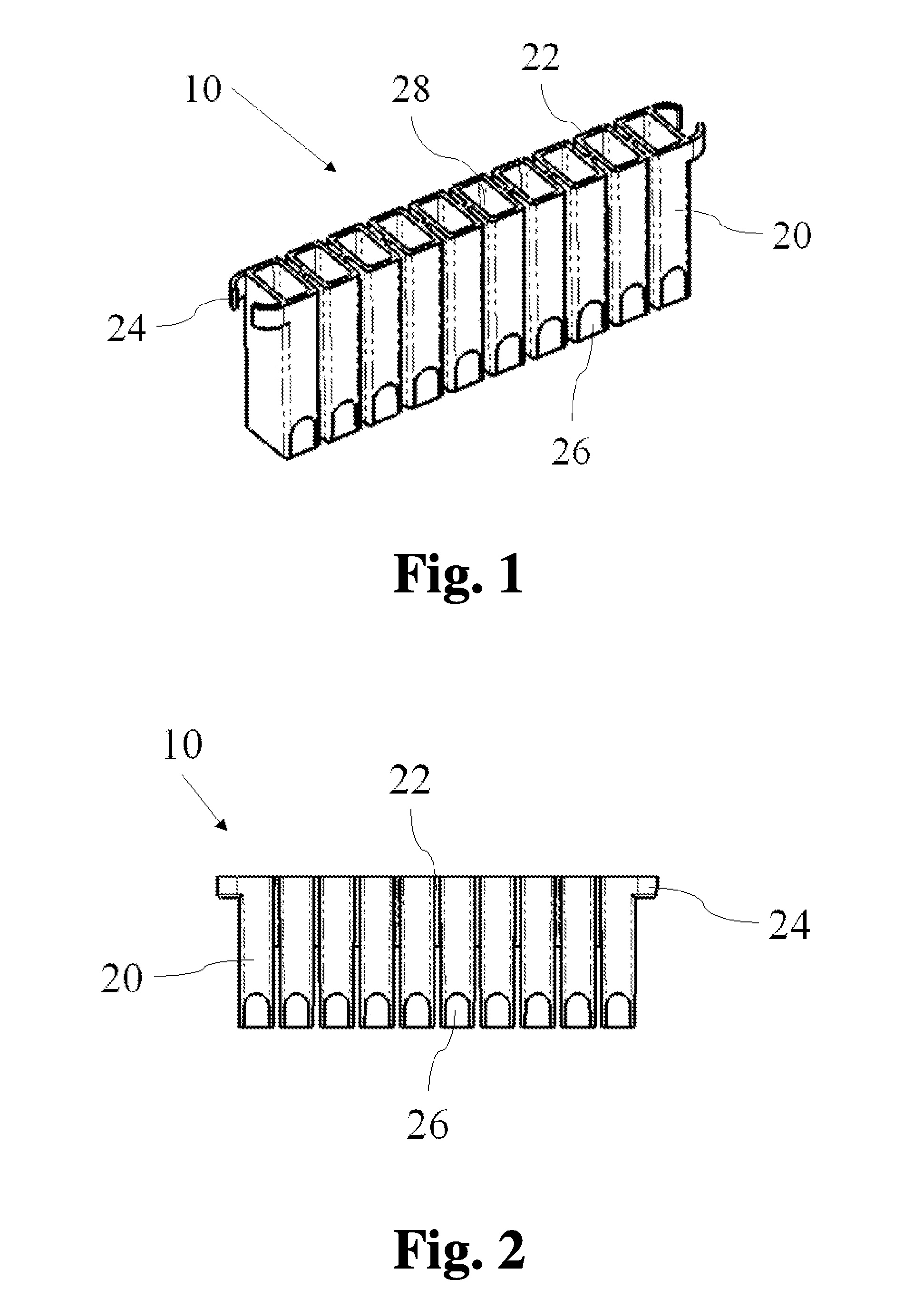

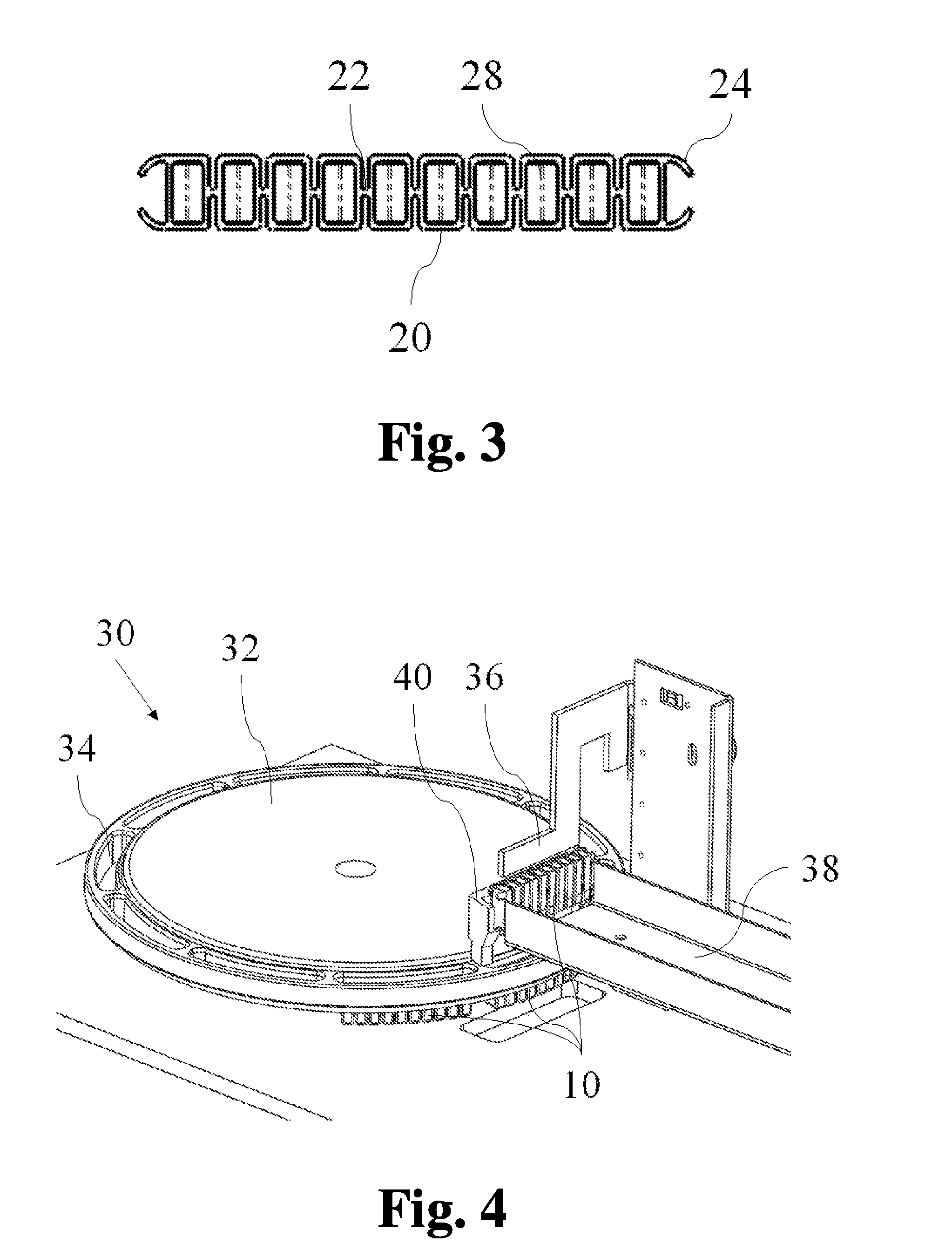

[0021]As illustrated in FIG. 1, the cuvette 10 comprises positions 20, which are in line next to each other. By a cuvette 10 is meant in this context a sample-receiving member with at least one position 20 for receiving the sample and for storage at least during analysis. The position 20 is a tubular vessel wherein a confined sample space 28 for a sample to be analyzed is formed and which is limited by the walls of the vessel. The position 20 has, according to one embodiment, a rounded quadrangular shaped cross-section and is generally shaped such that the sides of the opening of the sample space 28 are considerably shorter than the depth thereof. The sample space 28 can also have another shape. In this context, the direction of the longest side of the sample space 28 of the position 20, i.e. the depth, is called the vertical axis. Correspondingly by a horizontal axis is meant the Cartesian axes orthogonal to the vertical axis.

[0022]The cuvette 10 has, according to one embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com