Submerging offshore support structure

a support structure and submerged technology, applied in the direction of bulkheads/piles, foundation engineering, construction, etc., can solve the problems of reducing the economic benefits of offshore wind turbine placement, reducing the economic benefits of wind turbine placement, and increasing costs, so as to increase wind-driven energy production and economic benefits. stable and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

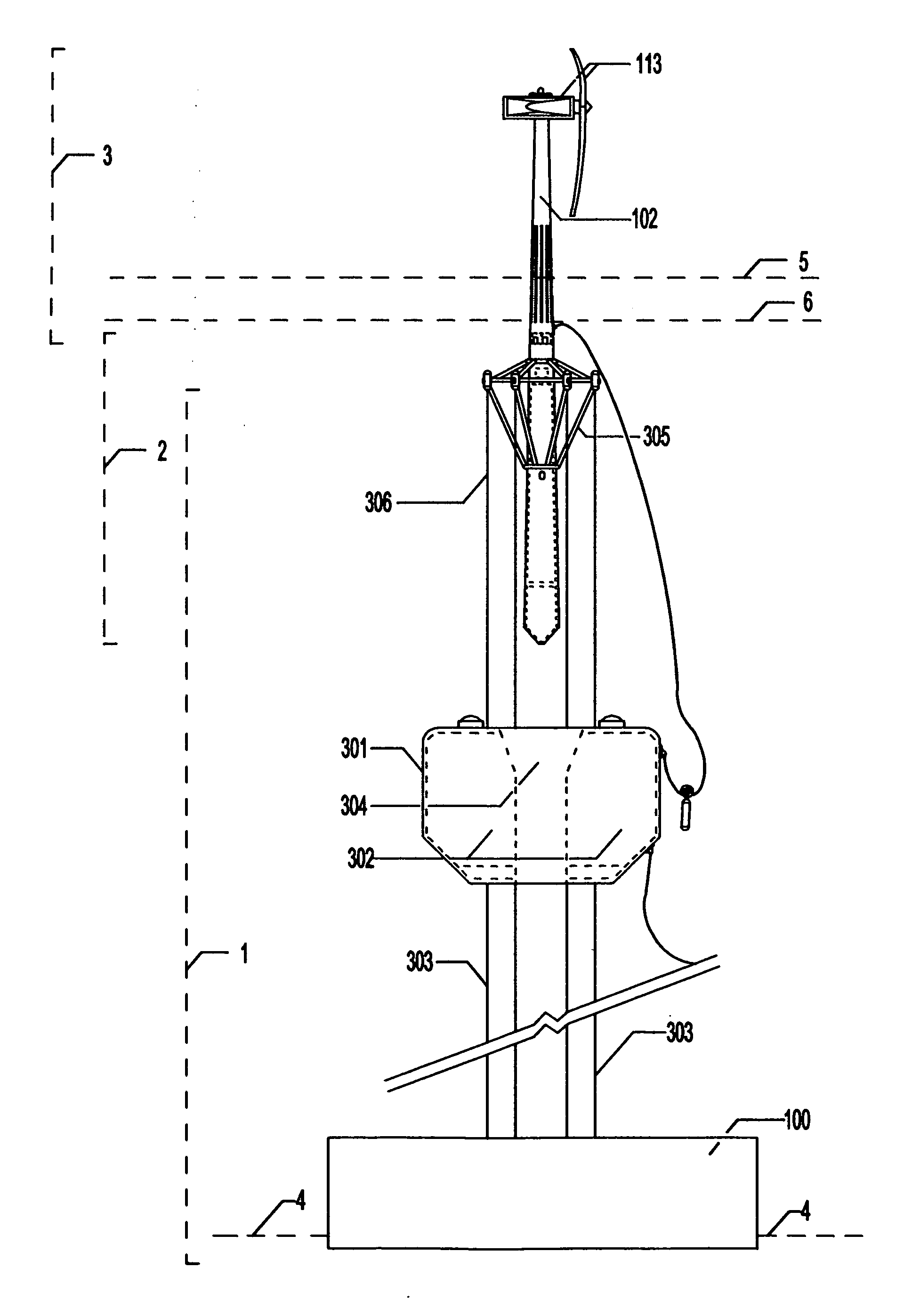

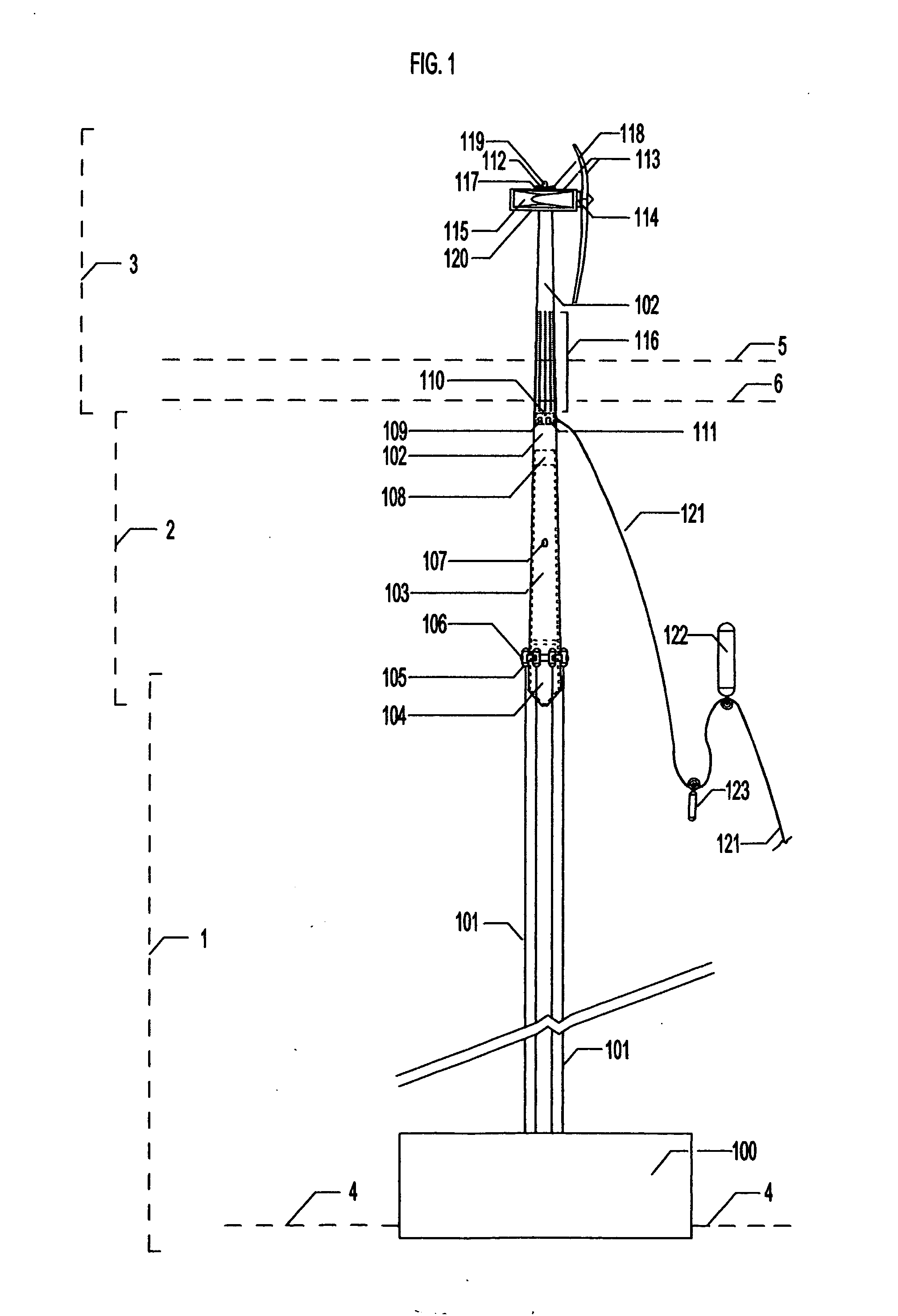

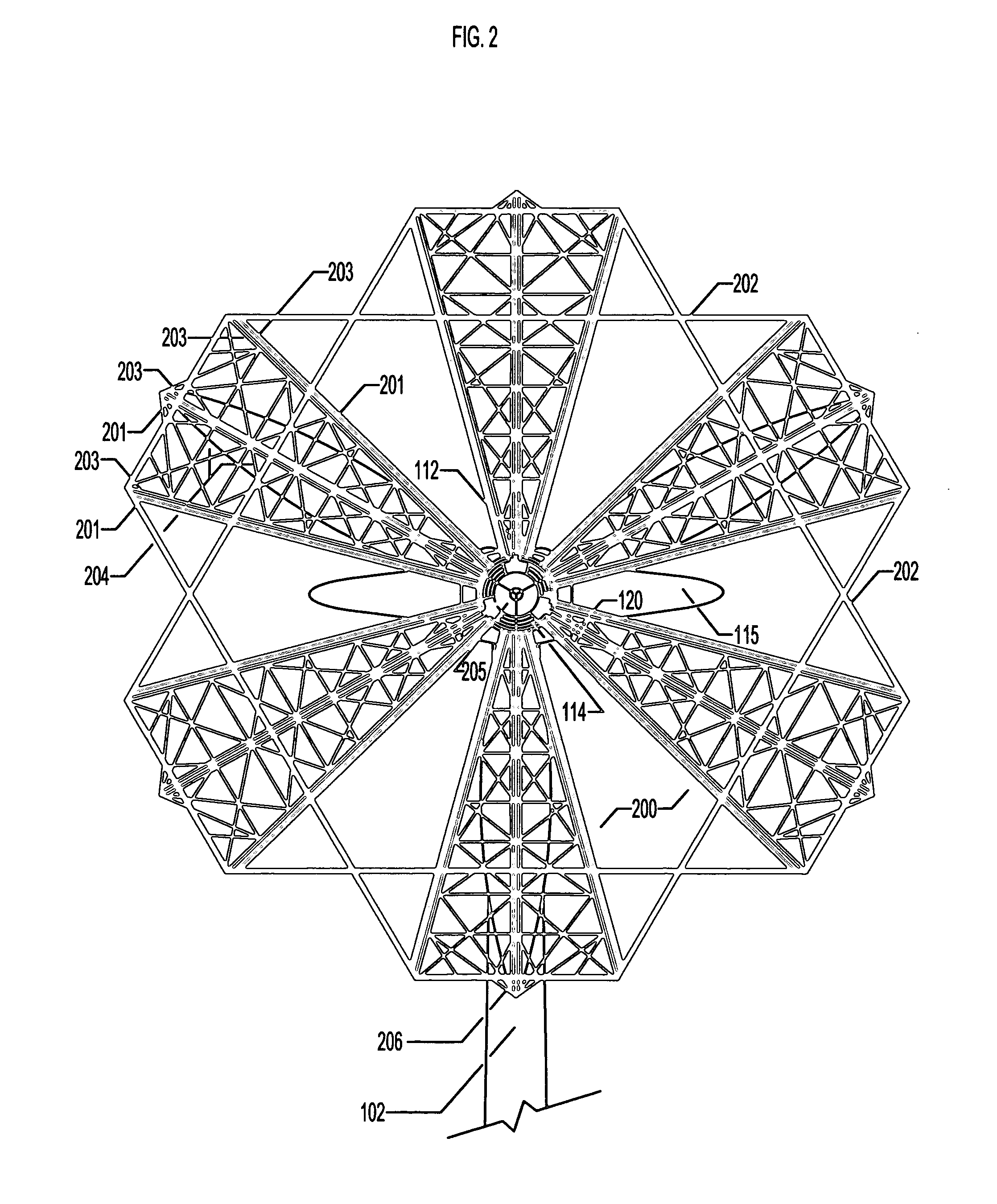

[0041]The support structure gains advantage from being located off shore, by being situated beyond the visible range of persons located on shore, yet is positioned closer to large urban demand than most metropolitan areas allow for land-based sitting. This reduces the power transmission distance while gaining access to increased wind speeds. The term “wind turbine” is meant to describe all components of a wind turbine's system including mechanical and electrical systems' parts typically used to convert, regulate, or store power output, so that a wind turbine may be made to economically serve an electrical power transmission grid.

[0042]Corrosion-resistant materials, such as Ferro-Cement, corrosion-resistant alloys, non-metallic materials such as plastics, ceramics, glass, graphite, and composite materials such as fiberglass or carbon-fiber reinforced plastic, are used throughout the structure wherever possible to increase strength and resistance to the caustic environment while simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com