Shape memory alloy (SMA) actuators and devices including bio-inspired shape memory alloy composite (bismac) actuators

a technology of bio-inspired shape and memory alloy, applied in the field of actuators, can solve the problems of few, if any, new devices developed, few, if any, successful applications developed, and largely defeats the advantages derived from the use of sma materials. , to achieve the effect of only a relatively small motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

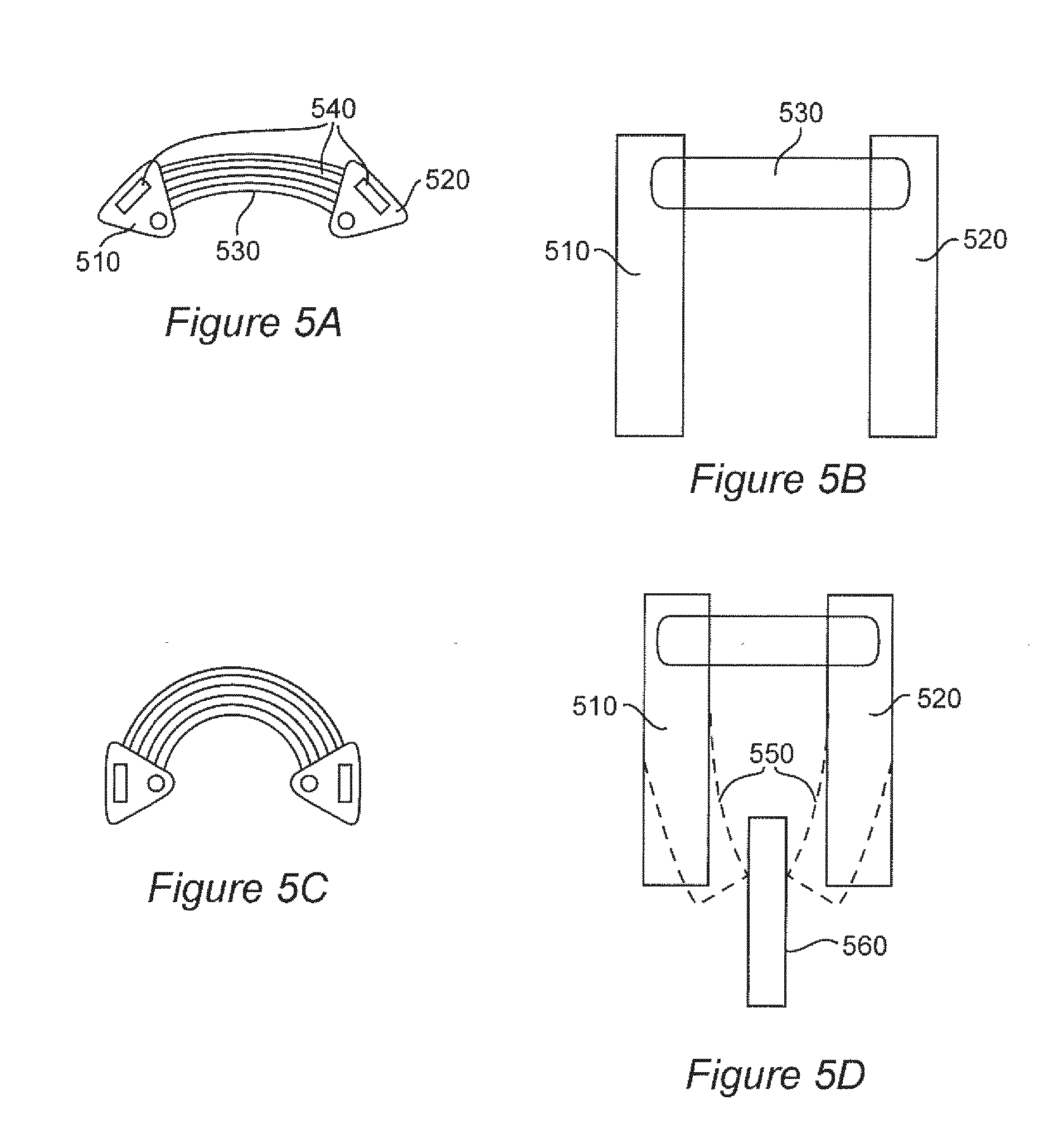

[0024]Referring now to the drawings, and more particularly to FIGS. 1A and 1B, a generalized form of an actuator in accordance with the invention is shown in cross-sectional and side views, respectively. For simplicity of illustration, all of FIGS. 1B, 2B, 3A, 3B and 4 are assumed to be cantilevered from the rightmost end thereof as depicted in FIG. 12. In its simplest form, the actuator 100 in accordance with the invention comprises only three elements: a spring beam 110 (hereafter sometime simply “beam”), an SMA element 120 and an encapsulation body 130. The beam 110 is preferably a highly flexible material such as spring steel and having a rectangular cross-section tending to flex in a preferential direction determined by its thickness relative to its width to constrain and define the motion of the actuator. The SMA element 120 can be any known or foreseeable SMA material and is preferably in the form of a wire of circular cross-section in order to minimize effects on actuator sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com