Multi-Port Ignition System for a Sectional Furnace

a technology of ignition system and sectional furnace, which is applied in the direction of burner control device, combustion type, failure to detect, etc., can solve the problems of single flame sensor not being able to determine the faulty burner, single flame sensor not being able to detect, and present technology not being able to accurately and quickly discern the status of each and every flam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

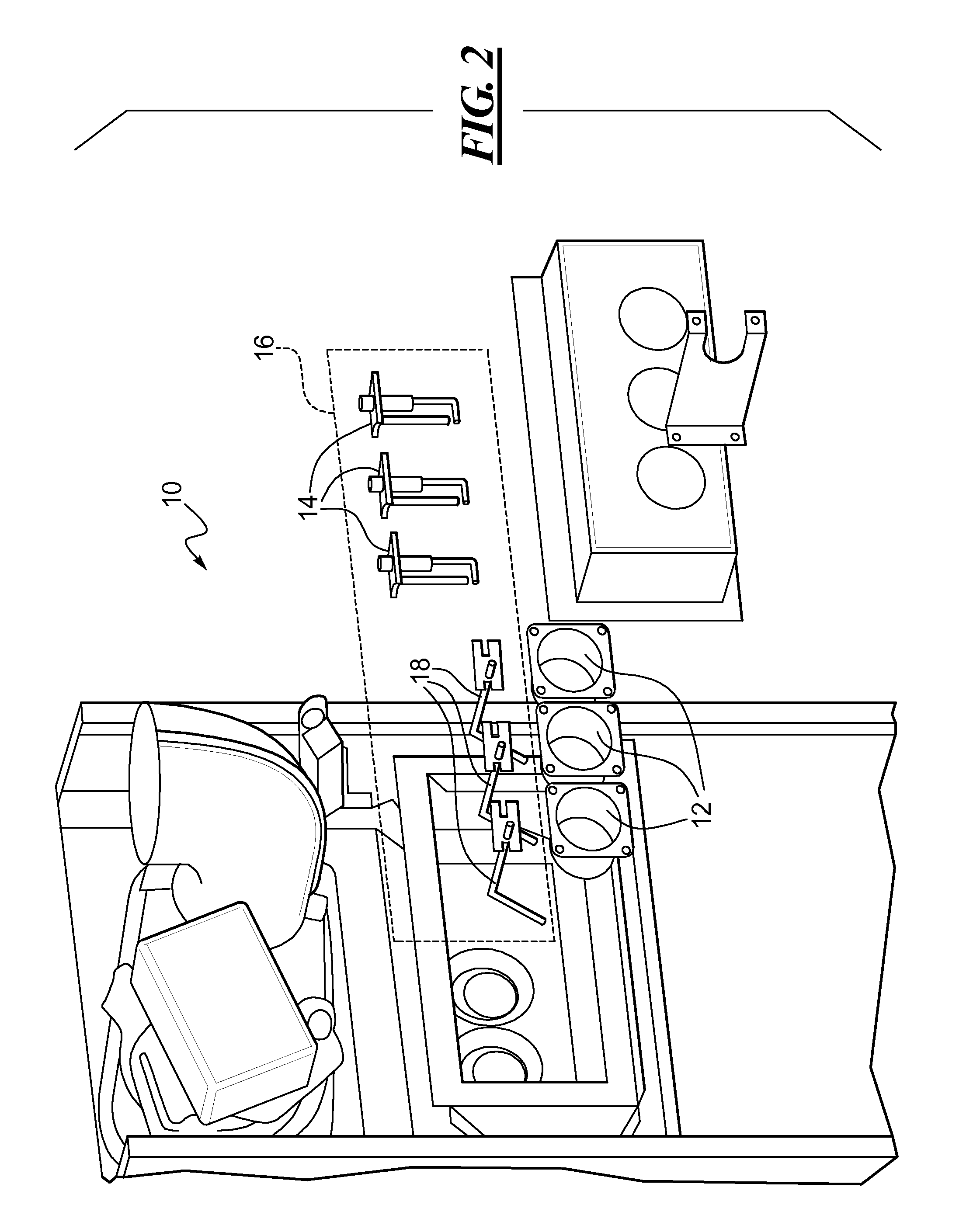

[0018]Referring to the drawings and with particular reference to FIG. 2, an exemplary ignition system for a gas furnace is provided and referred to as reference number 16. It is understood that the teachings of the disclosure may be used to construct ignition systems above and beyond those specifically disclosed below. One of ordinary skill in the art will readily understand that the following are only exemplary embodiments.

[0019]Turning to FIG. 2, a typical sectional gas furnace 10 is provided having one or more burners 12 each corresponding to one or more heat exchangers (not shown) that may be disposed within the gas furnace 10. Each of the burners 12 may be individually provided with a corresponding igniter 14, or alternatively, the burners 12 may share a single igniter 14. Each igniter 14 may be positioned in close proximity to an inlet of its corresponding burner 12 and adapted to ignite a flame using a spark gap, or the like. The gas furnace 10 may also be provided with an ig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com