Method and system for the torrefaction of lignocellulosic material

a technology of lignocellulosic material and torrefaction method, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, solid fuels, etc., can solve the problems of low gas mass at atmospheric pressure, unpressurized reaction vessels, etc., and achieve the effect of increasing the mass and speeding up the heating of biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

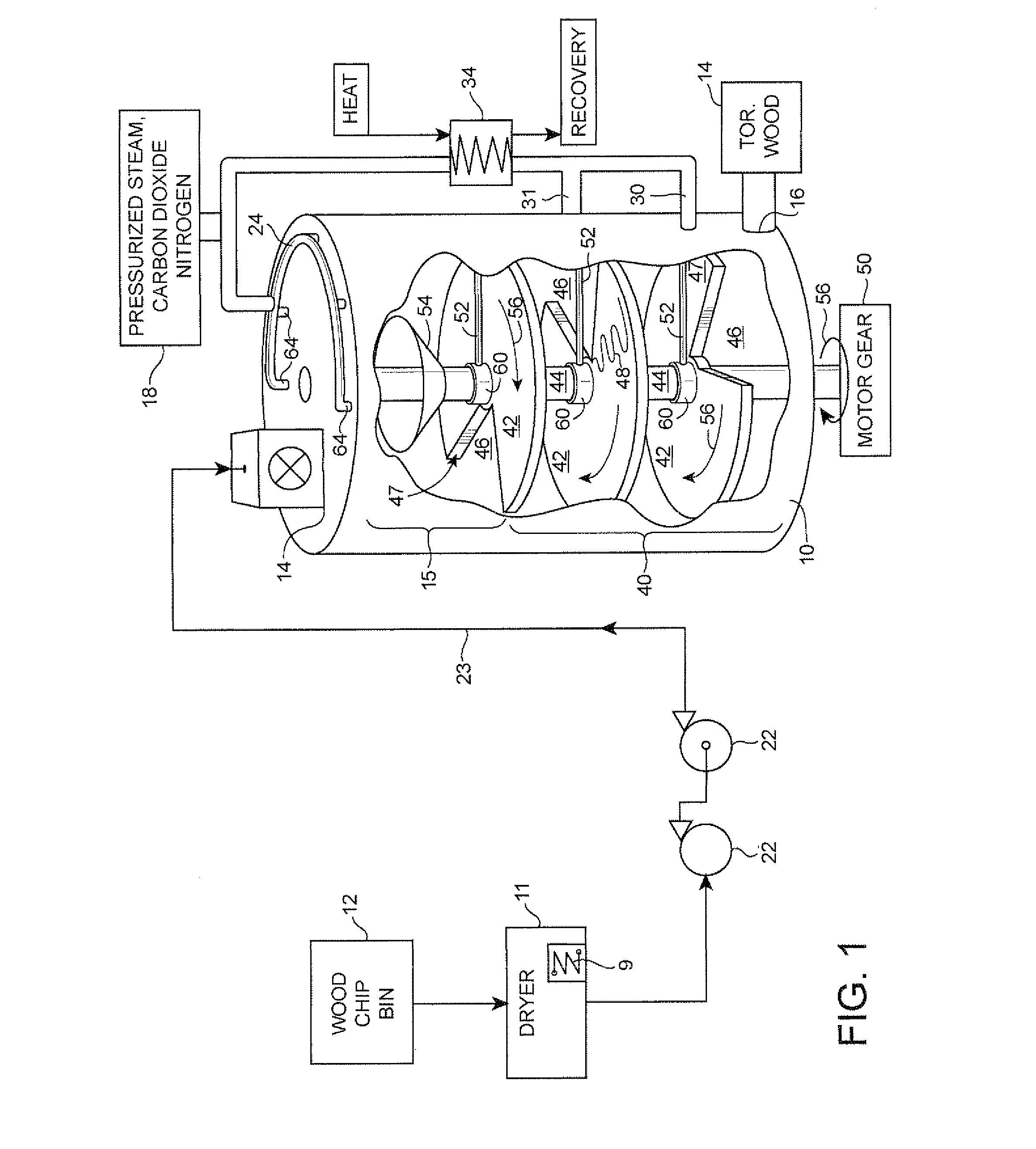

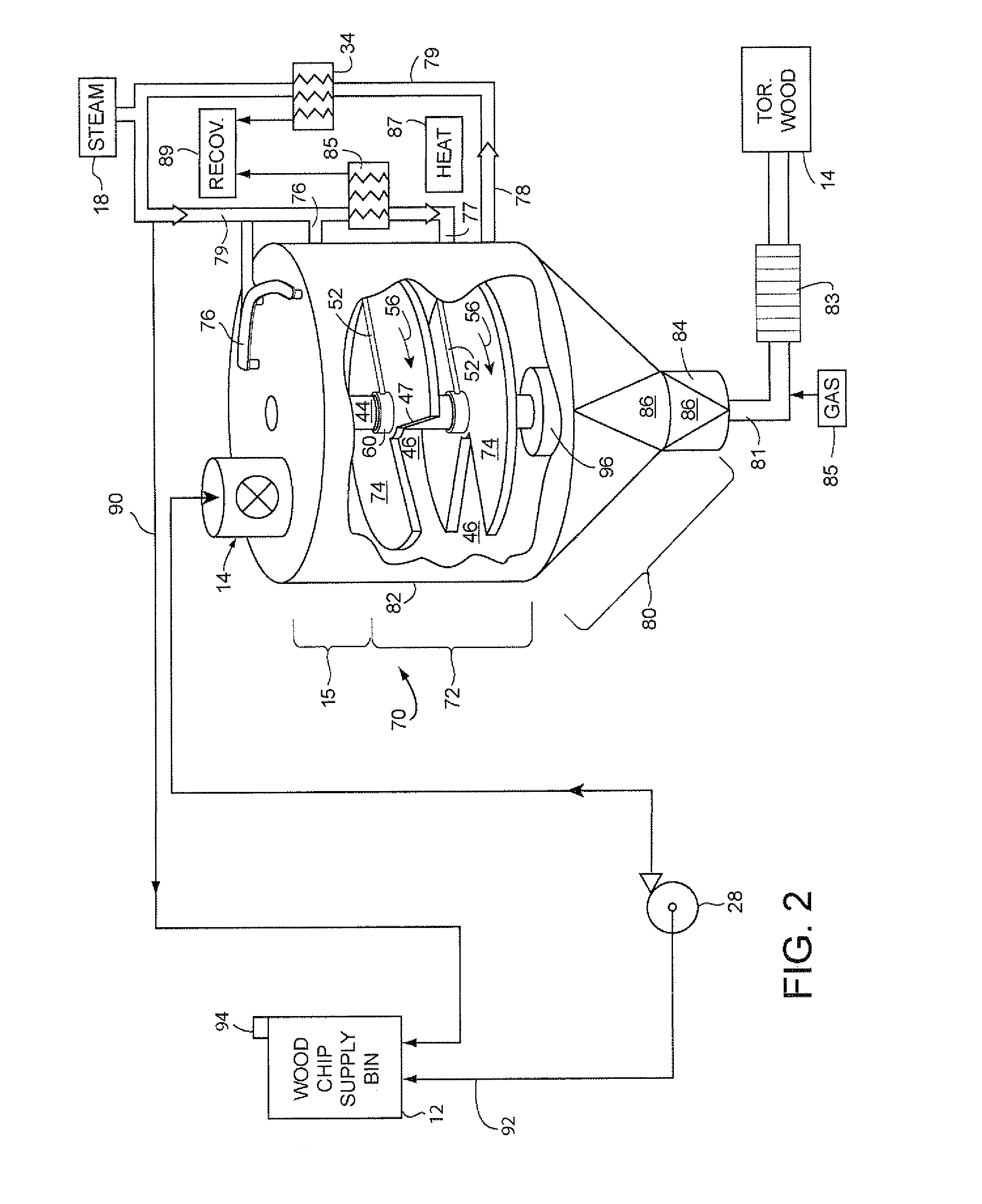

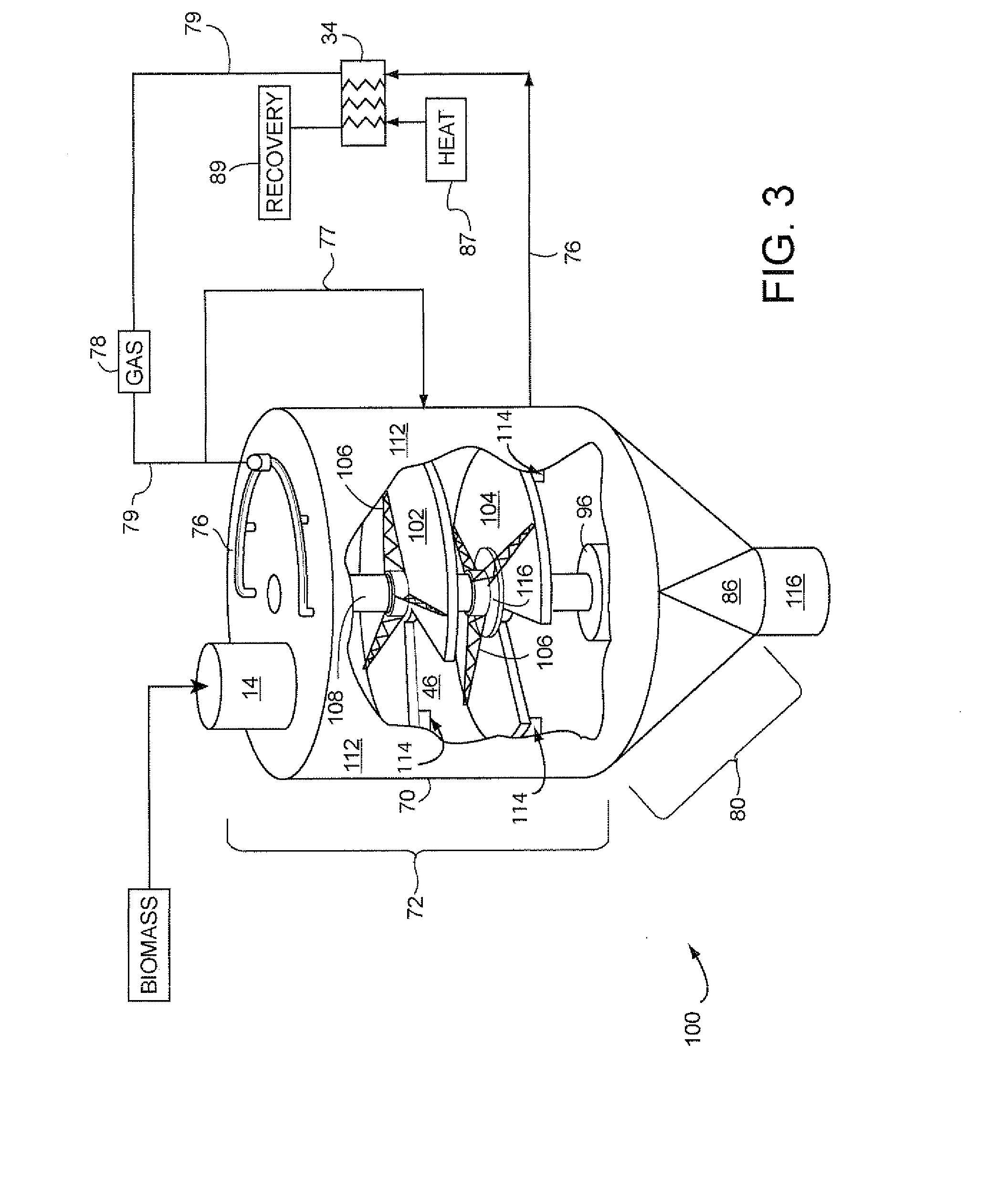

[0019]FIG. 1 is schematic diagram of a pressurized treatment vessel 10 for receiving, from a storage bin 12, biomass material, such as wood chips, wood pulp and other comminuted cellulosic material. The biomass enters the pressurized treatment vessel through an upper inlet 14. The upper inlet may be a high pressure transfer device that allows biomass at atmospheric pressure to be transferred into the high pressure vessel. Alternatively, the biomass may be pressurized by a high pressure feeder (HPF) or a series of chip pumps 22 as the pressurized biomass flows through a conduit 23 to the upper inlet which may be an open valve.

[0020]Within the vessel, the biomass is subjected to a torrefaction reaction and is discharged as torrefied biomass 14 from a lower discharge outlet 16 of the vessel. Before the torrefaction reaction occurs in the vessel, the biomass may be dried and heated in an inert environment to a temperature of 200° C. to 400° C. The biomass may be dried and heated in a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com