System and method for casting and rolling metal

a technology of metal casting and metal rolling, applied in the field of installation and a method of casting and rolling metal, can solve the problems of space, energy, and expense, and achieve the effects of high aluminum content, rapid solidification, and better utilization of rolling trains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

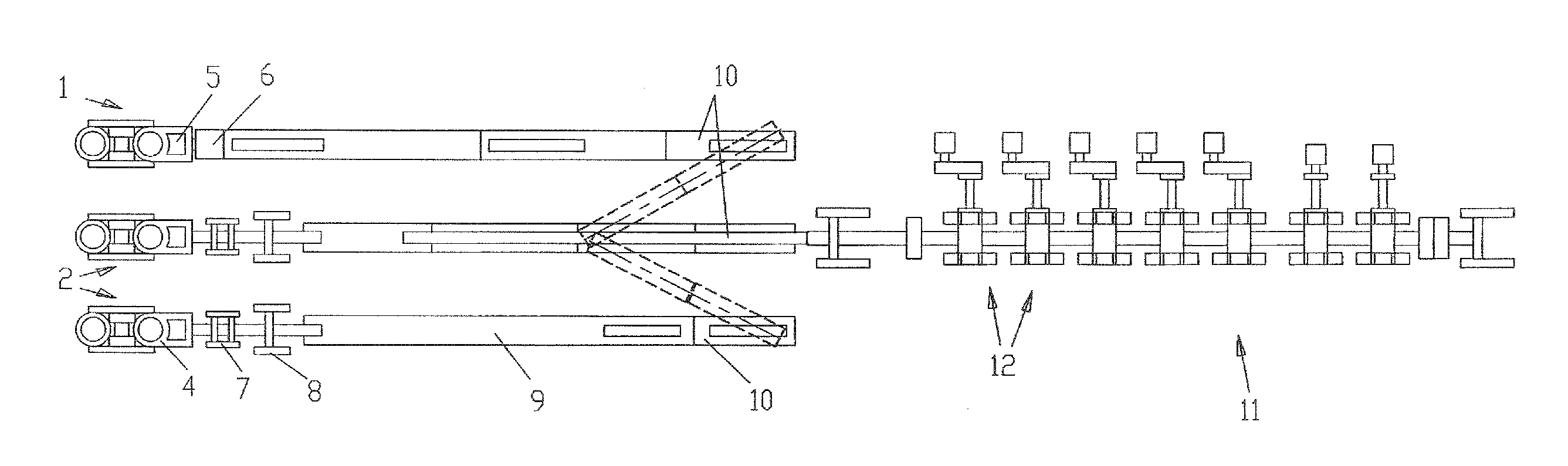

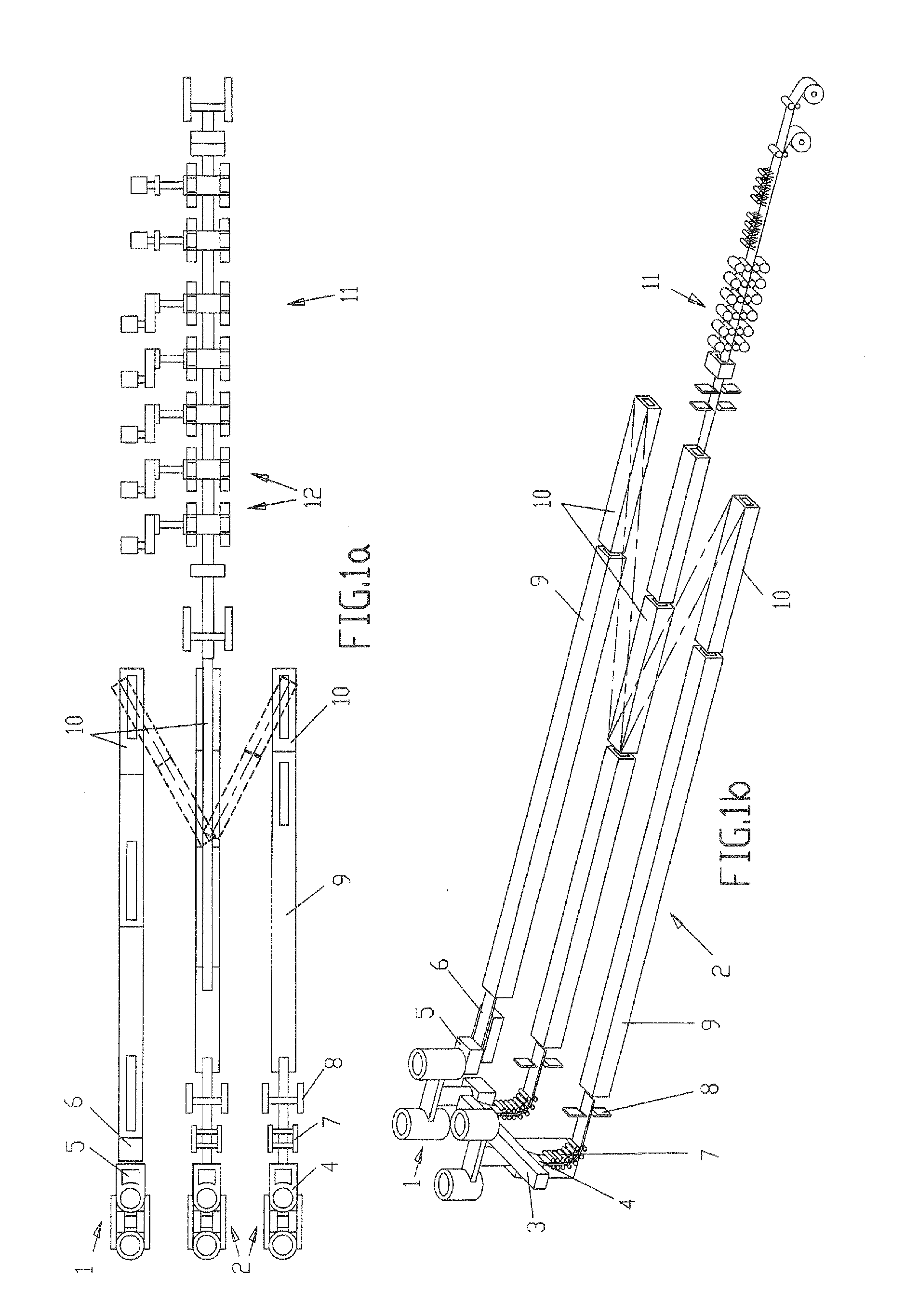

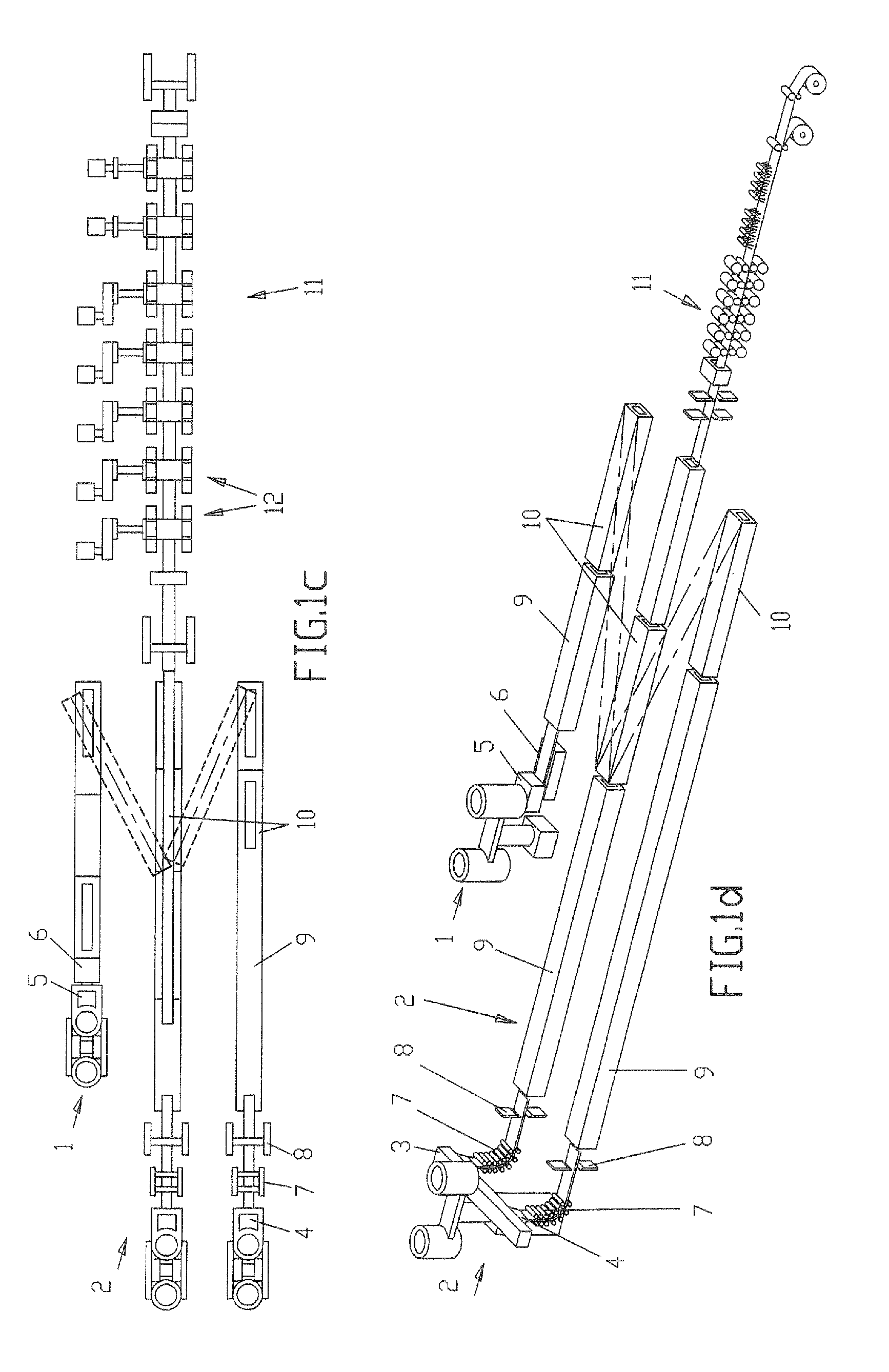

[0033]FIG. 1a shows a specific embodiment of an installation of the invention with two CSP installations 2 or vertical thin-slab casting installations 2. These vertical thin-slab casting installations 2 in themselves are already well known. In these installations 2, a strand is first vertically cast with a mold 4 and then bent by a bending device 7 and subsequently straightened with a straightening unit. Optionally, a cutting unit 8 or shears 8 are provided farther along in the direction of casting. The slabs then arrive in a downstream temperature-adjusting unit 9, especially a furnace 9, where, for example, they can be heated or held at a certain temperature.

[0034]A horizontal thin-slab casting installation 1 is arranged alongside the two CSP casting installations 2. This installation is preferably located parallel next to one of the vertical thin-slab casting installations 2. The installation 1, which is shown at the top in FIG. 1a, has a charging vessel 5 for the melt and a conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com