Cell culture method, cell culture device, method for counting subsject matters to be counted in container and device for counting

a cell culture method and cell culture technology, applied in the field of cell culture methods, cell culture devices, methods for counting subsject matter in containers and counting devices, can solve the problems of degrading proliferation efficiency, degrading proliferation efficiency, and not using agitating blades with cells subject to damage, so as to improve cell proliferation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

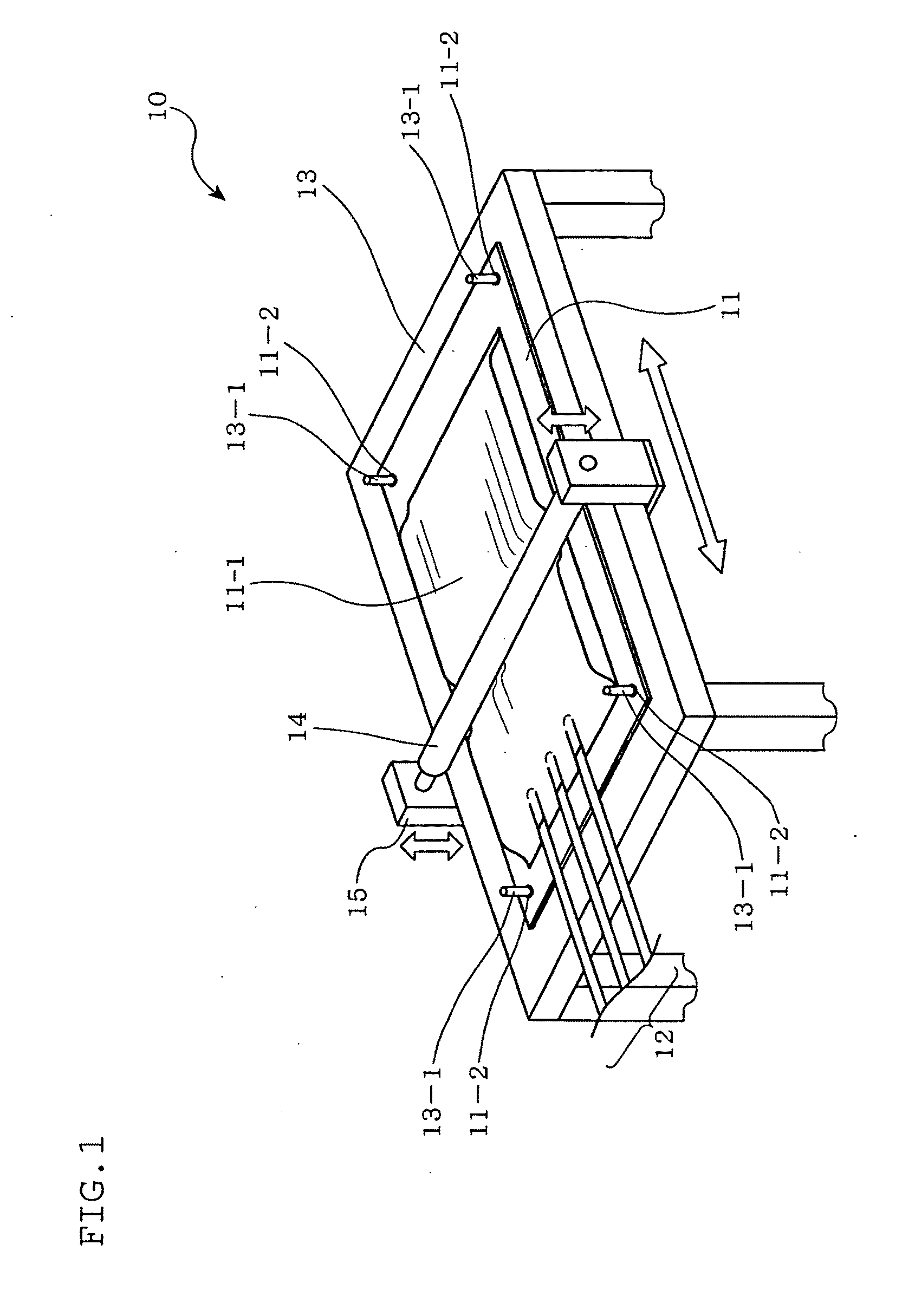

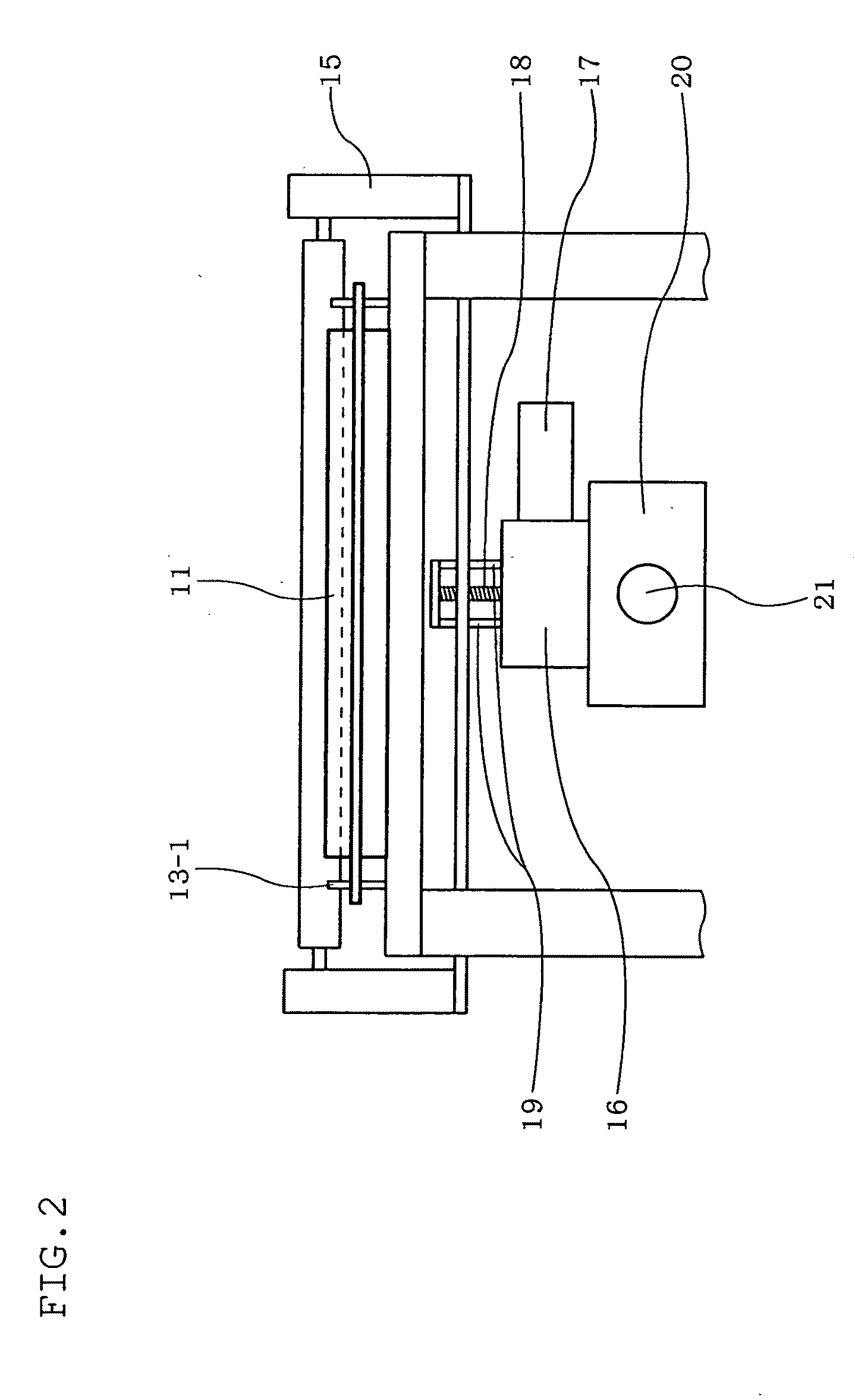

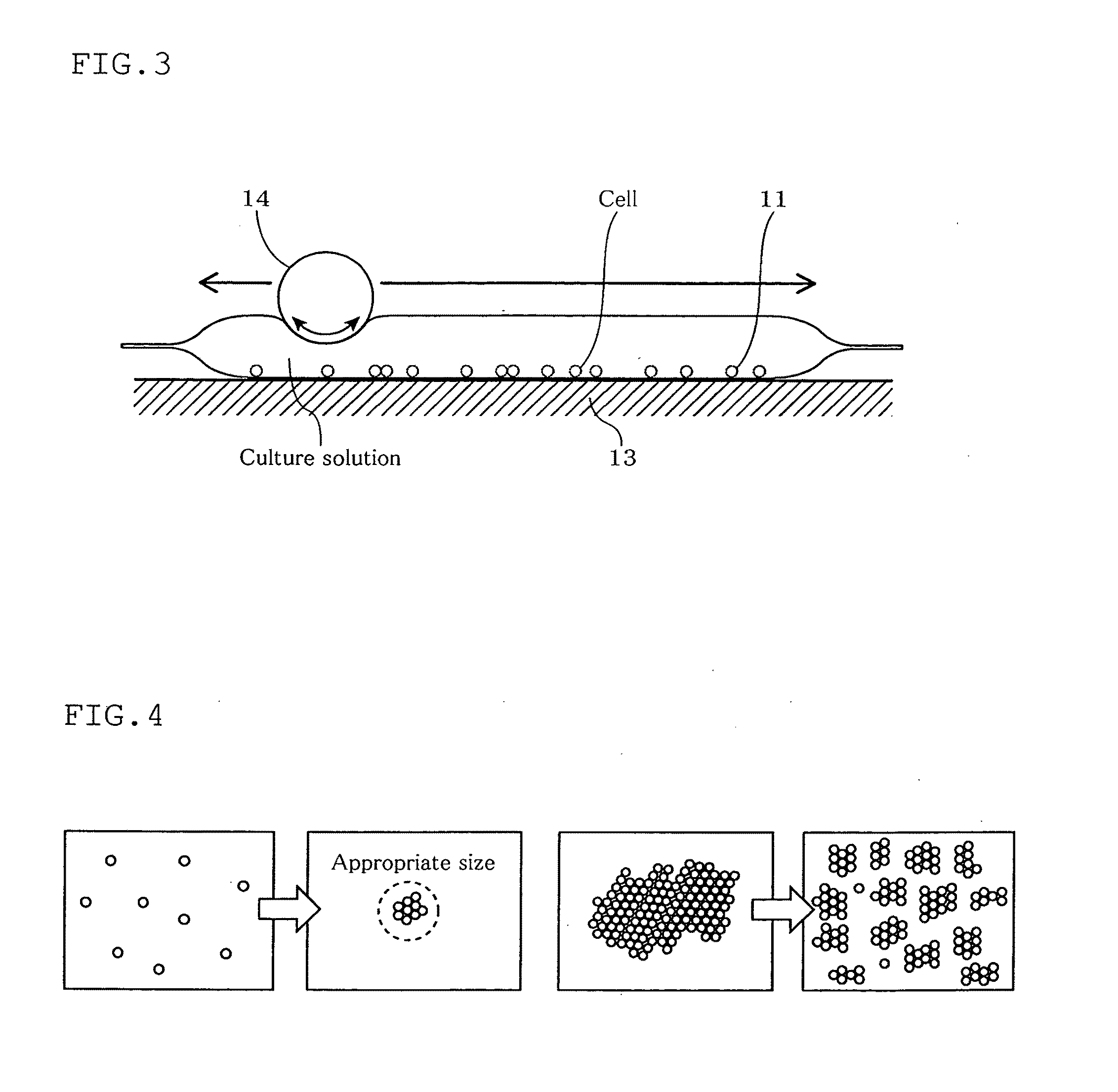

[0066]First, referring to FIG. 1 through FIG. 4, a first embodiment of the present invention will be described. FIG. 1 is a diagram illustrating the cell culturing apparatus according to this embodiment. FIG. 2 is a diagram illustrating a driving device of the cell culturing apparatus according to this embodiment. FIG. 3 is a schematic side view of the cell culturing apparatus according to this embodiment. FIG. 4 is a diagram illustrating formation of an aggregate of cells and disintegration of the aggregate of cells in the present invention.

[Cell Culturing Apparatus 10]

[0067]As shown in FIG. 1, a cell culturing apparatus 10 according to this embodiment includes a culture container 11, a loading base 13, and an agitating member 14. A culture solution (culture medium) and cells are enclosed within a storage 11-1 of the culture container 11, and tubes 12 are coupled to the storage 11-1.

[0068]The culture container 11 is a container that is made of a soft packing material shaped in the ...

second embodiment

[0098]Next, referring to FIG. 5, a second embodiment of the present invention will be described. The figure is a diagram illustrating the cell culturing apparatus according to this embodiment.

[0099]This embodiment is different from the first embodiment in that the cell culturing apparatus 10 has the culture container 11 divided into a culture portion and an expansion portion by a partition member so as to make the capacity of the culture medium adjustable to an appropriate size in accordance with the proliferation of cells, with the culture portion being agitatable by the agitating member 14 (agitating roller). Further, in this embodiment, both ends of the culture container 11 are secured by clamp members 23. This embodiment is otherwise similar to the first embodiment.

[0100]That is, as shown in FIG. 5, in the cell culturing apparatus 10 according to this embodiment, the culture container 11 is divided by partition rollers (partition member) 22 to provide a culture portion in which ...

third embodiment

[0106]Next, a third embodiment of the present invention will be described by referring to FIG. 6. This figure is a diagram illustrating the cell culturing apparatus 10 according to this embodiment.

[0107]This embodiment is different from the first embodiment in the following respects. The cells in the culture container 11 are photographed. Whether the size of an aggregate is within a predetermined range is determined automatically. The size of aggregates is adjusted to an appropriate size based on the determination. This embodiment is otherwise similar to the first embodiment.

[0108]Specifically, as shown in FIG. 6, the cell culturing apparatus 10 according to this embodiment includes a photographing device 30 and a control device 40, in addition to the configuration of the first embodiment.

[0109]Upon receipt of instruction information of photographing from the control device 40, the photographing device 30 photographs the cells in the culture container 11, and transmits the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com