Mortar and debris collection system

a collection system and debris technology, applied in the field ofmortar and debris collection devices, can solve the problems of inability to collect mortar and debris, and achieve the effect of enhancing hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

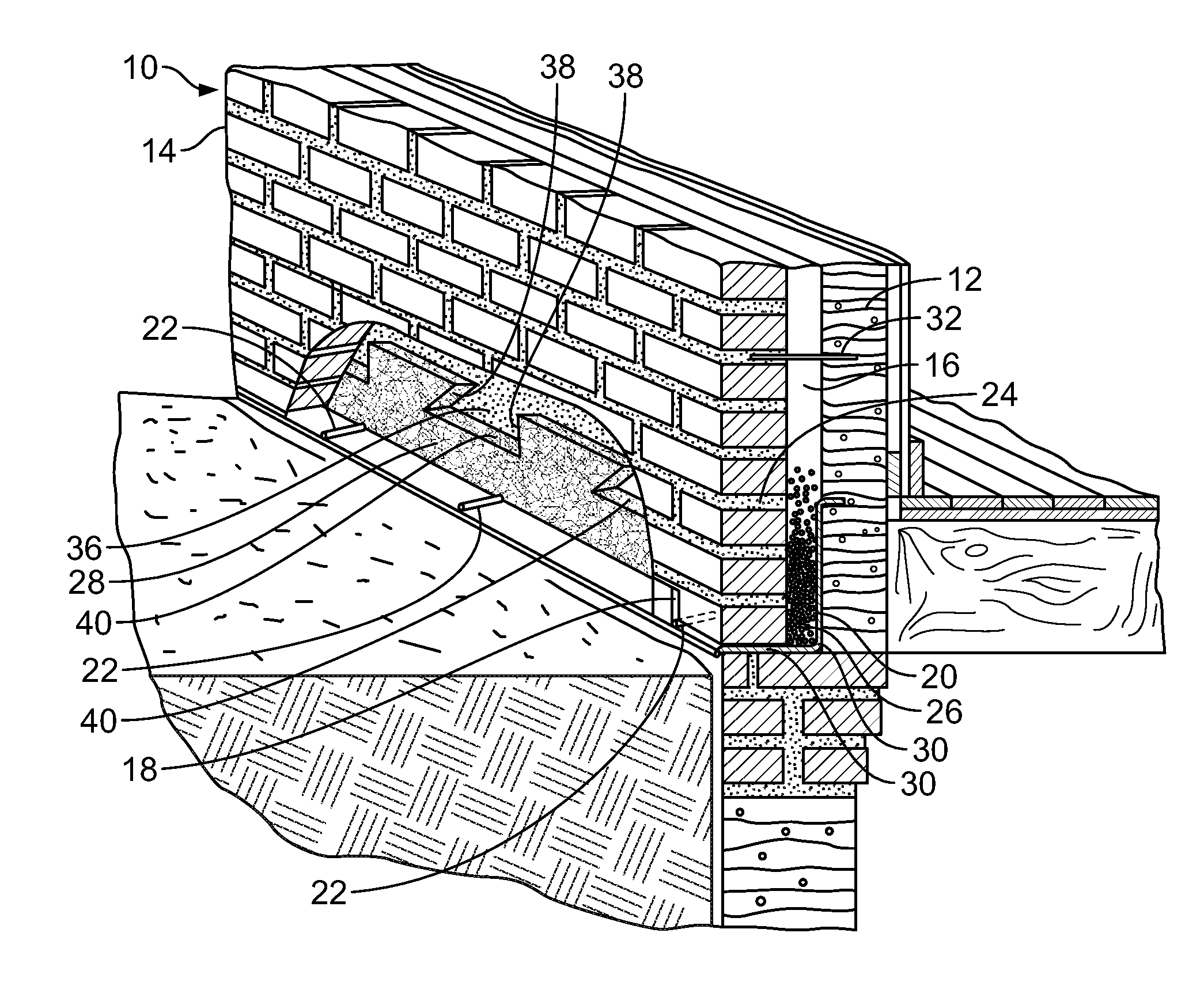

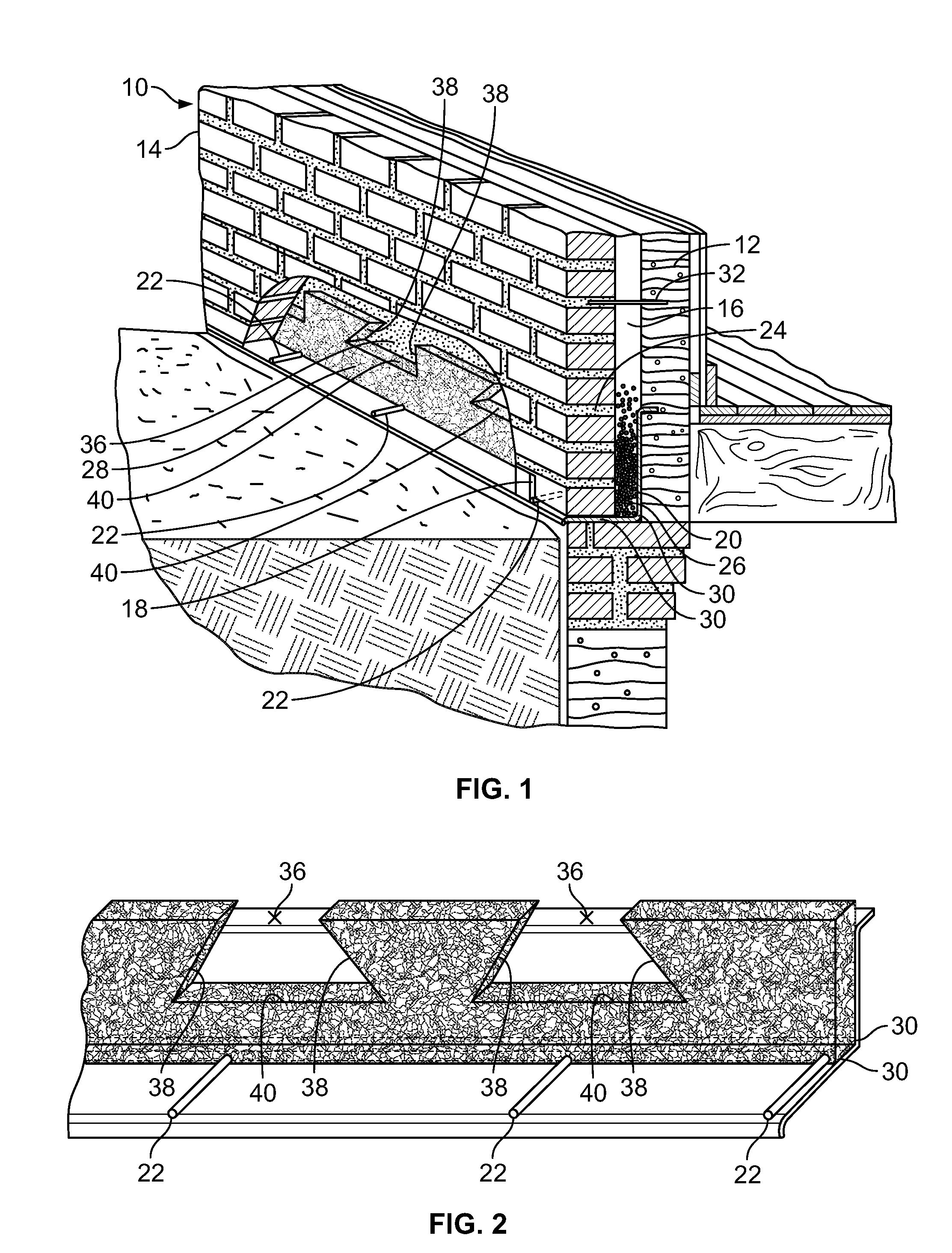

first embodiment

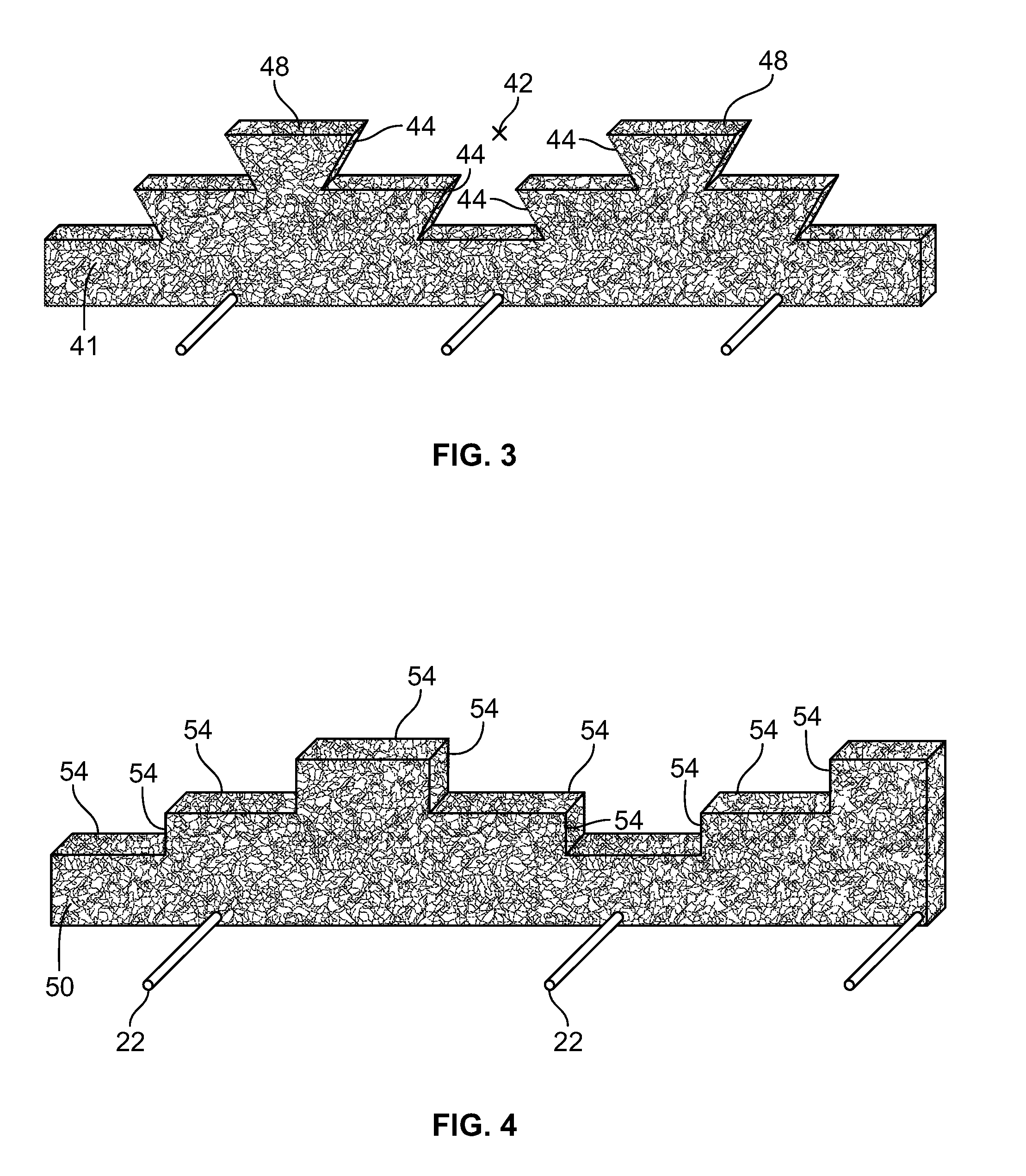

[0094]Referring to FIG. 13 there is shown yet another embodiment of the invention wherein the same reference numerals from the first embodiment followed by a double prime sign are used to identify common elements. Device 120″ includes a strip of material 132″ adjacent the intersection of the central portion 136″ and the lower portion 138″. A plurality of spaced apart tubes or channels 146 are formed in the upper surface of lower portion 138″ extending about to lip 144″ to create the weep holes within the mortar joint. The tubes or channels 146 alternatively may be integrally formed as a separate member or members positioned immediately adjacent the upper surface of portion 138″. The tubes or channels 146 may be positioned over mesh strips 142 as shown in FIG. 11.

[0095]Referring to FIG. 14, there is shown still another embodiment of the invention wherein the same reference numerals from the first embodiment followed by a triple prime sign are used to identify common elements. Device ...

embodiment 730

[0156]One feature of the illustrated embodiment 730 is that the drip edge 744 extends to a point 745 less than the terminus or end 747 of the flashing lower portion 740. This creates an overlapping portion or tab 749, preferably having a length of about 2 to 4 inches to overlap with an adjacent flashing member and the overlap may include a mesh drainage strip 717 preferably of enhanced hydrophobic material. Preferably, the vertical body 736 adjacent the end 747 is aligned with the end 745 of the drip edge 744. The vertical body 736 also preferably has a termination bar 756 along an upper edge thereof as in an above-detailed embodiment.

[0157]FIG. 36 shows yet another embodiment of the flashing and drainage system 830 according to the invention. The generally top-down view shows the system 830 flashing member 832. The flashing member 832 is a flattened sheet-like material sized and shaped to be used, for example, within a cavity wall 10 and more particularly in a building joint, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com