Optimal test flow scheduling within automated test equipment for minimized mean time to detect failure

a technology of automated test equipment and test flow, applied in the field of automation test equipment, can solve problems such as process defects, and achieve the effect of reducing the time to detect any defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

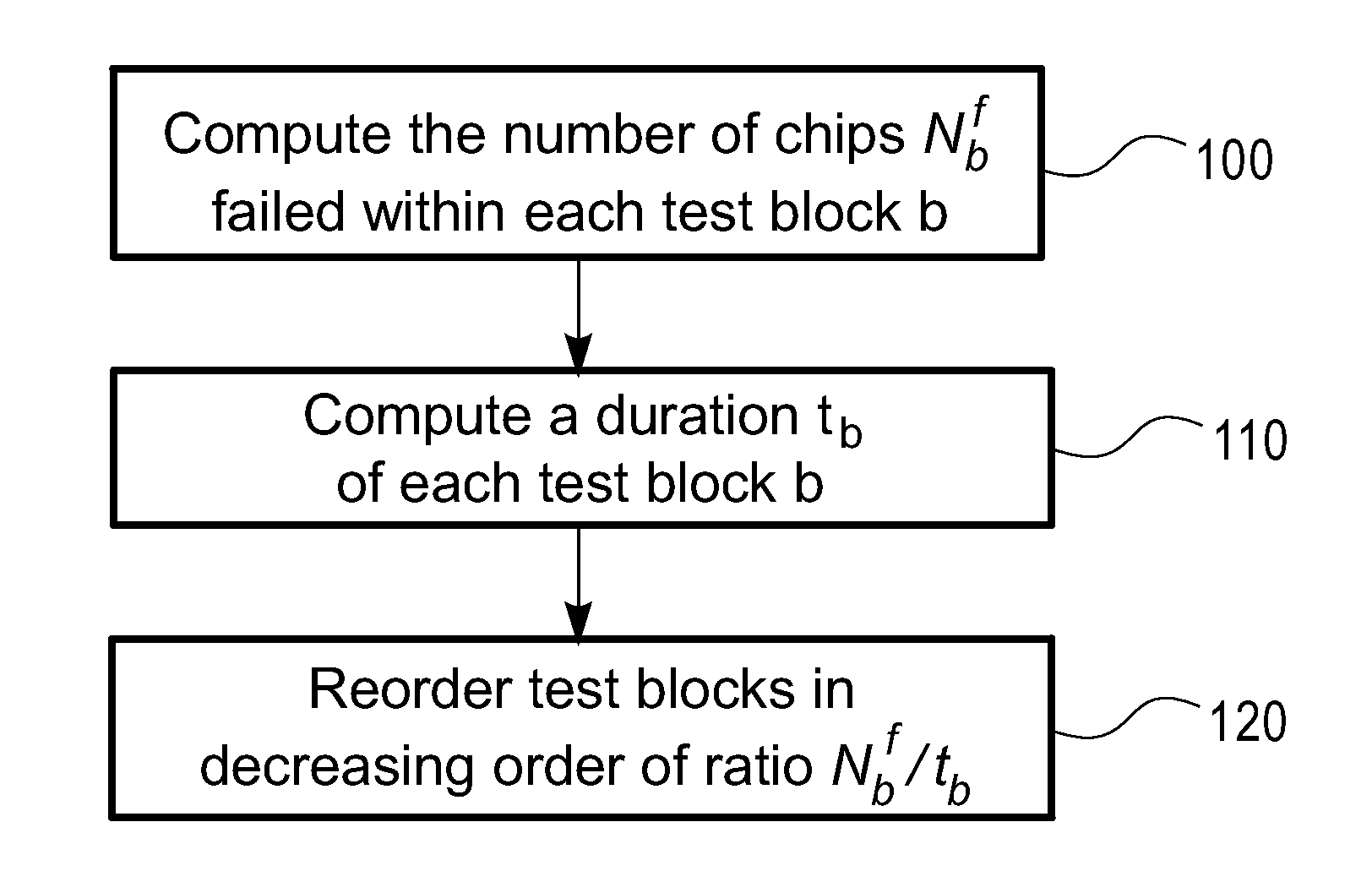

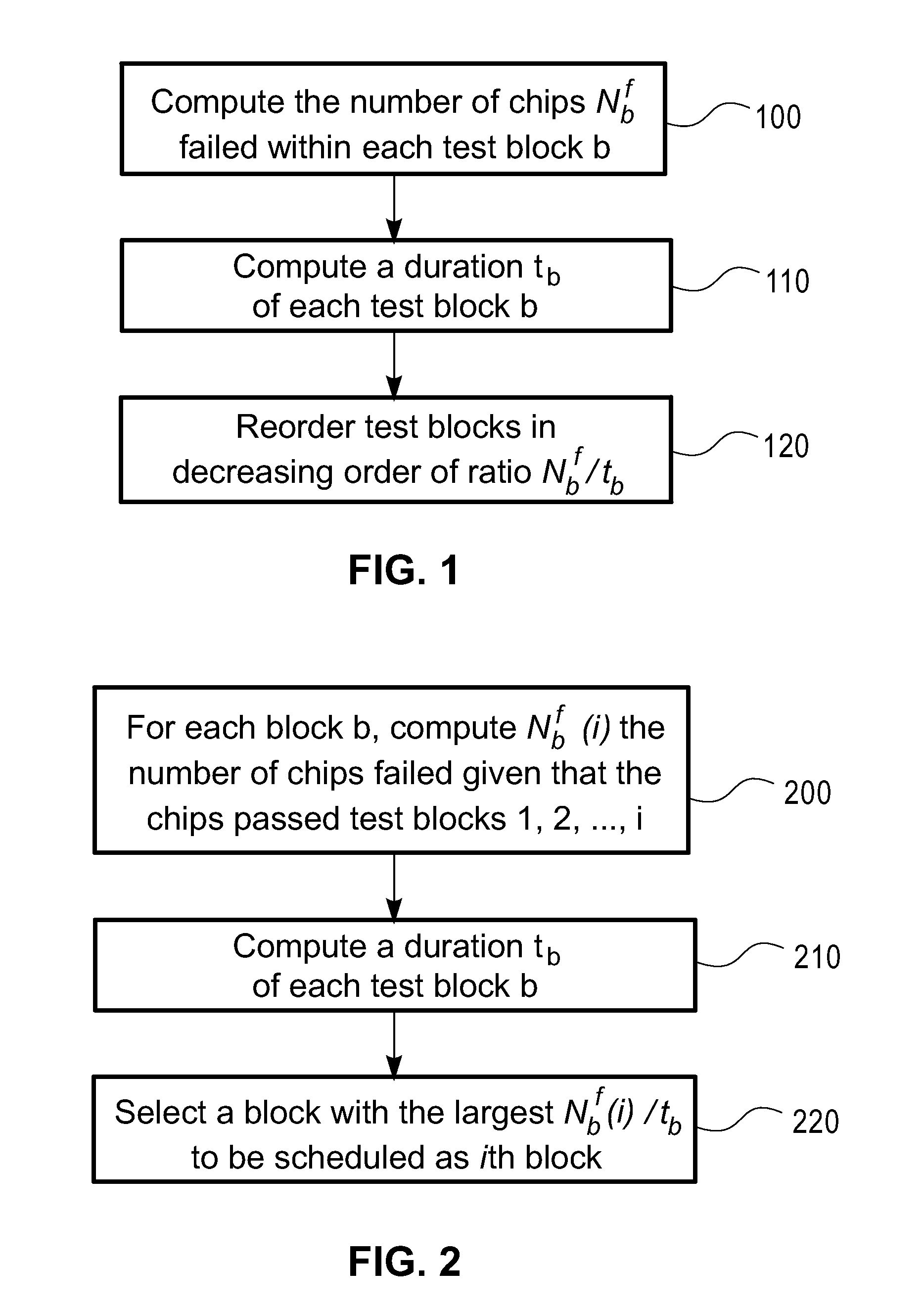

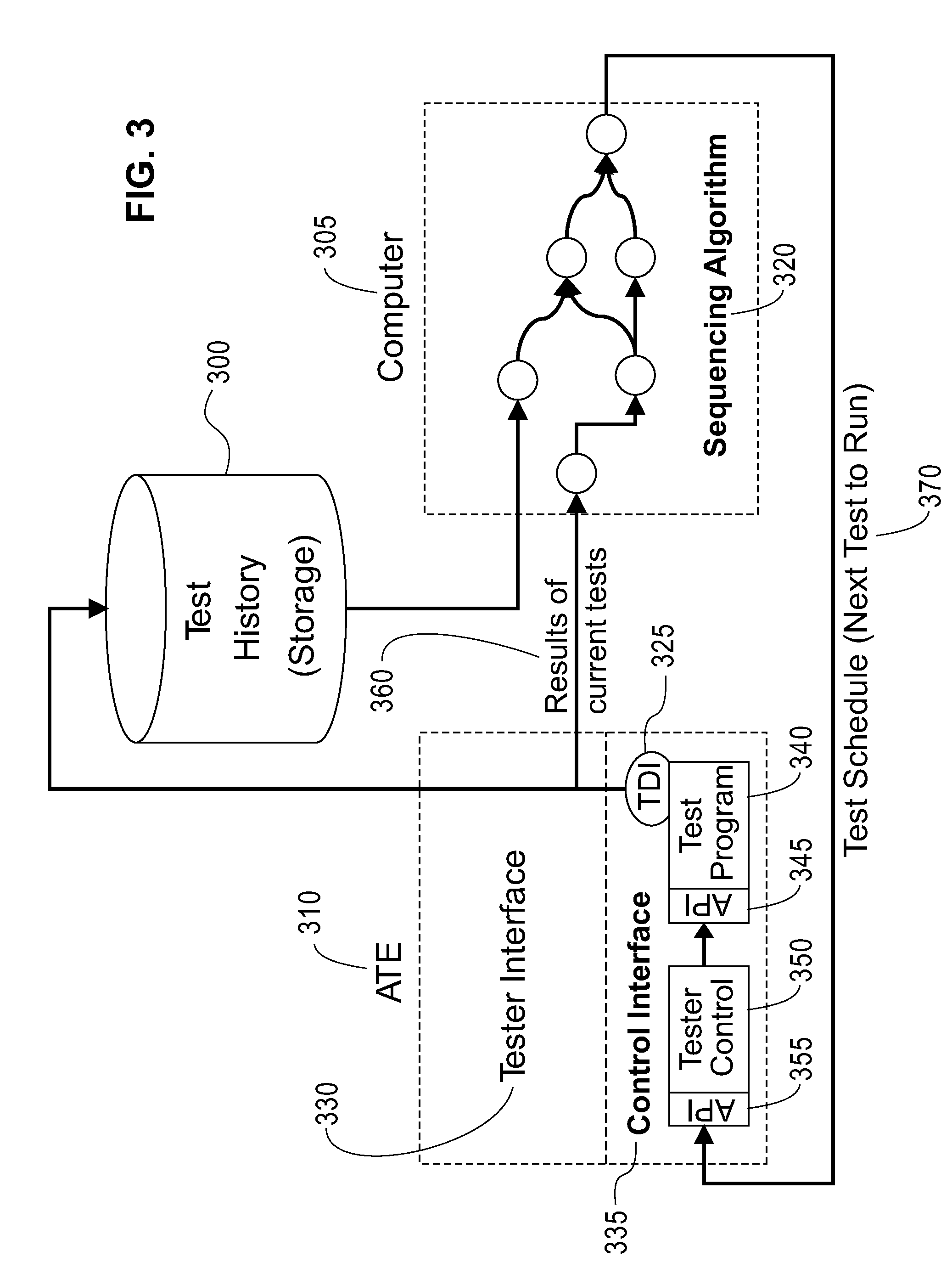

[0016]According to one embodiment of the present invention, a test floor may include a plurality of ATE stations (i.e., individual testers). An ATE station includes at least one test flow, which is defined by a test program (e.g., a test program 340 in FIG. 3). A test flow comprises a plurality of test blocks. The test flow lists the plurality of tests or test blocks in a sequence according to which they are run. A test block includes one or more individual tests, e.g., tests measuring leakage current and threshold voltage. The test block refers to a group of individual tests that could not or should not be separated. The individual tests in the test block need to be run together in a specific sequence. The individual testers may perform the individual tests.

[0017]According to one embodiment of the present invention, an ATE station receives as input one or more of: a test process structure, a test process constraint and a stopping criterion. The test process structure includes, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com