Ultra Low Phosphorus Lubricant Compositions

a technology of phosphorus lubricant and composition, applied in the direction of additives, lubricant compositions, petroleum industry, etc., can solve the problems of vehicles emit high levels of pollution, and affecting the performance of pollution control devices, etc., to achieve excellent fuel economy, low phosphorus content, and high molybedenum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

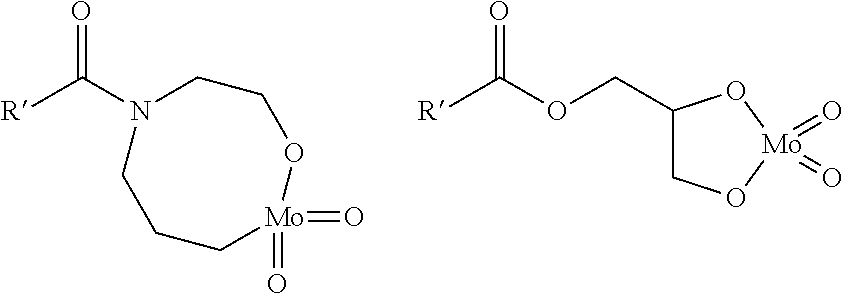

(1) Organomolybdenum Compound

A preferred organomolybdenum compound is prepared by reacting about 1 mole of fatty oil, about 1.0 to 2.5 moles of diethanolamine and a molybdenum source sufficient to yield about 0.1 to 12.0 percent of molybdenum based on the weight of the complex at elevated temperatures (i.e. greater than room temperature). A temperature range of about 70° to 160° C. is considered to be an example of an embodiment of the invention. The organomolybdenum component of the invention is prepared by sequentially reacting fatty oil, diethanolamine and a molybdenum source by the condensation method described in U.S. Pat. No. 4,889,647, incorporated herein by reference, and is commercially available from R.T. Vanderbilt Company, Inc. of Norwalk, Conn. as Molyvan® 855. The reaction yields a reaction product mixture. The major components are believed to have the structural formulae:

wherein R′ represents a fatty oil residue. An embodiment for the present invention are fatty oils ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com