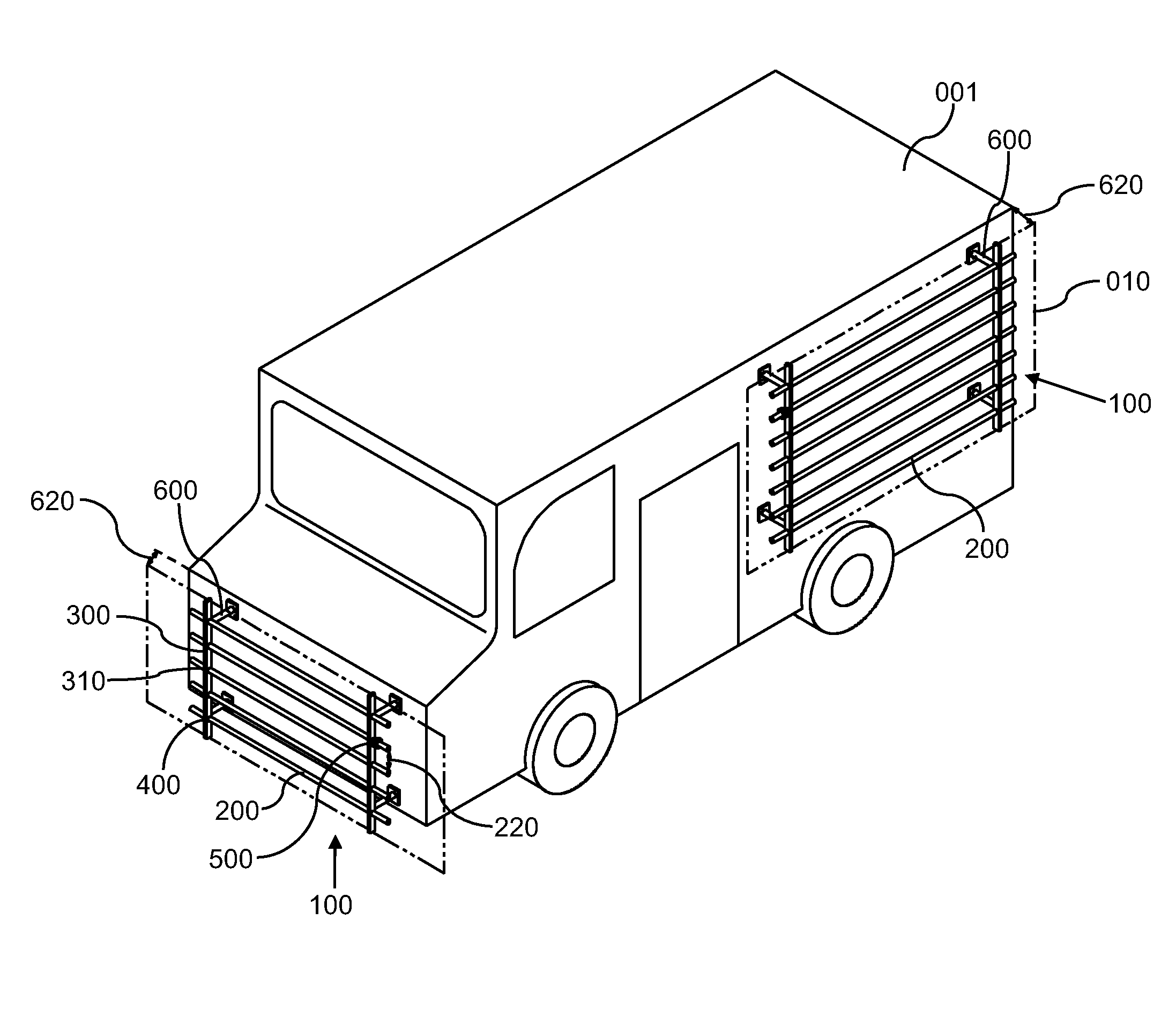

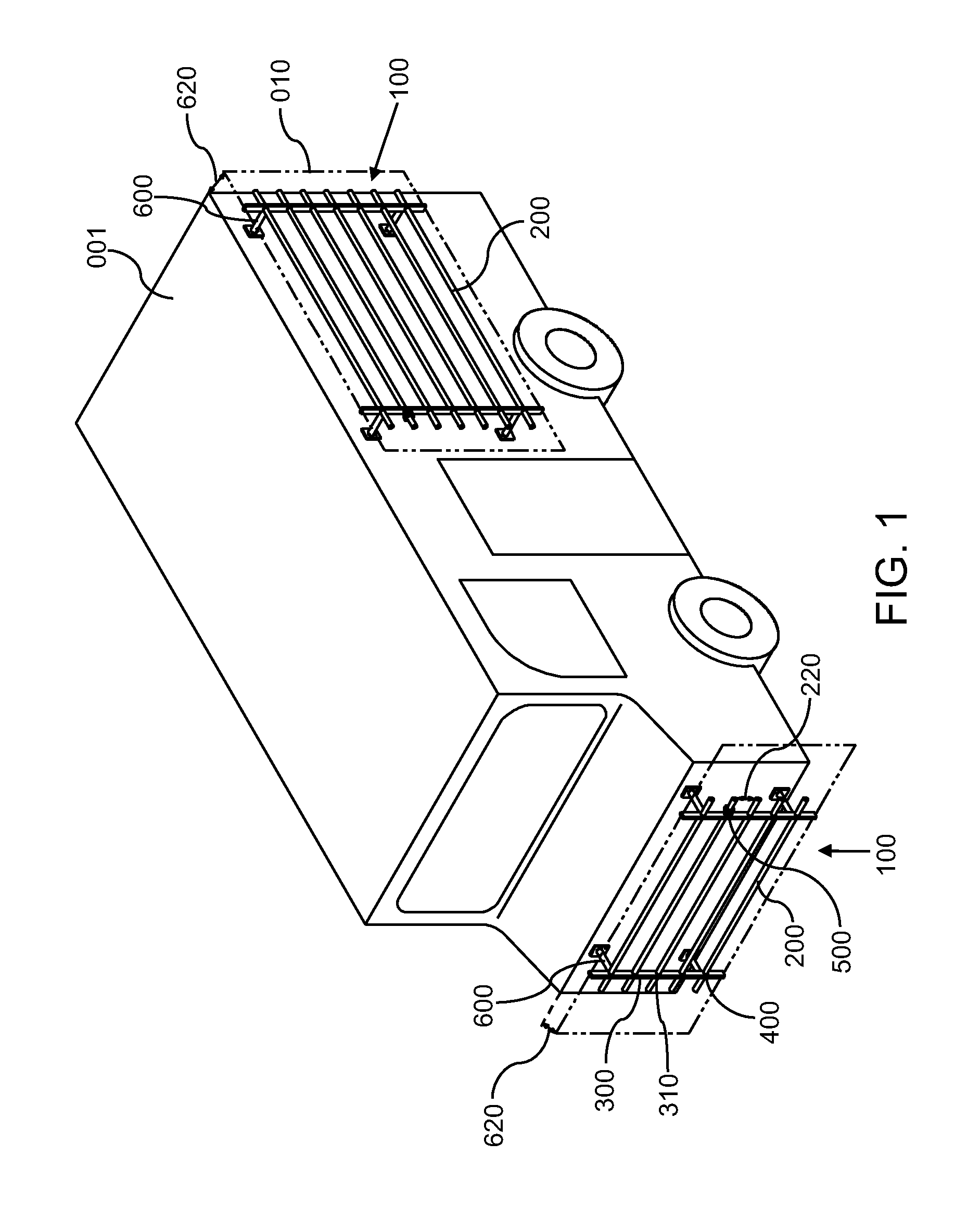

Bar armor system for protecting against rocket-propelled grenades

a technology of rocket-propelled grenades and armor systems, which is applied in the field of bar armor systems, can solve the problems of reducing the protection afforded by these systems, unable to prevent the detonation of rpgs, and cumbersome rpg standoff armor systems, and achieves the effects of preventing the translation of vertical bars, preventing the detonation of rpgs, and improving the geometry of rpg-shaped charge d

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

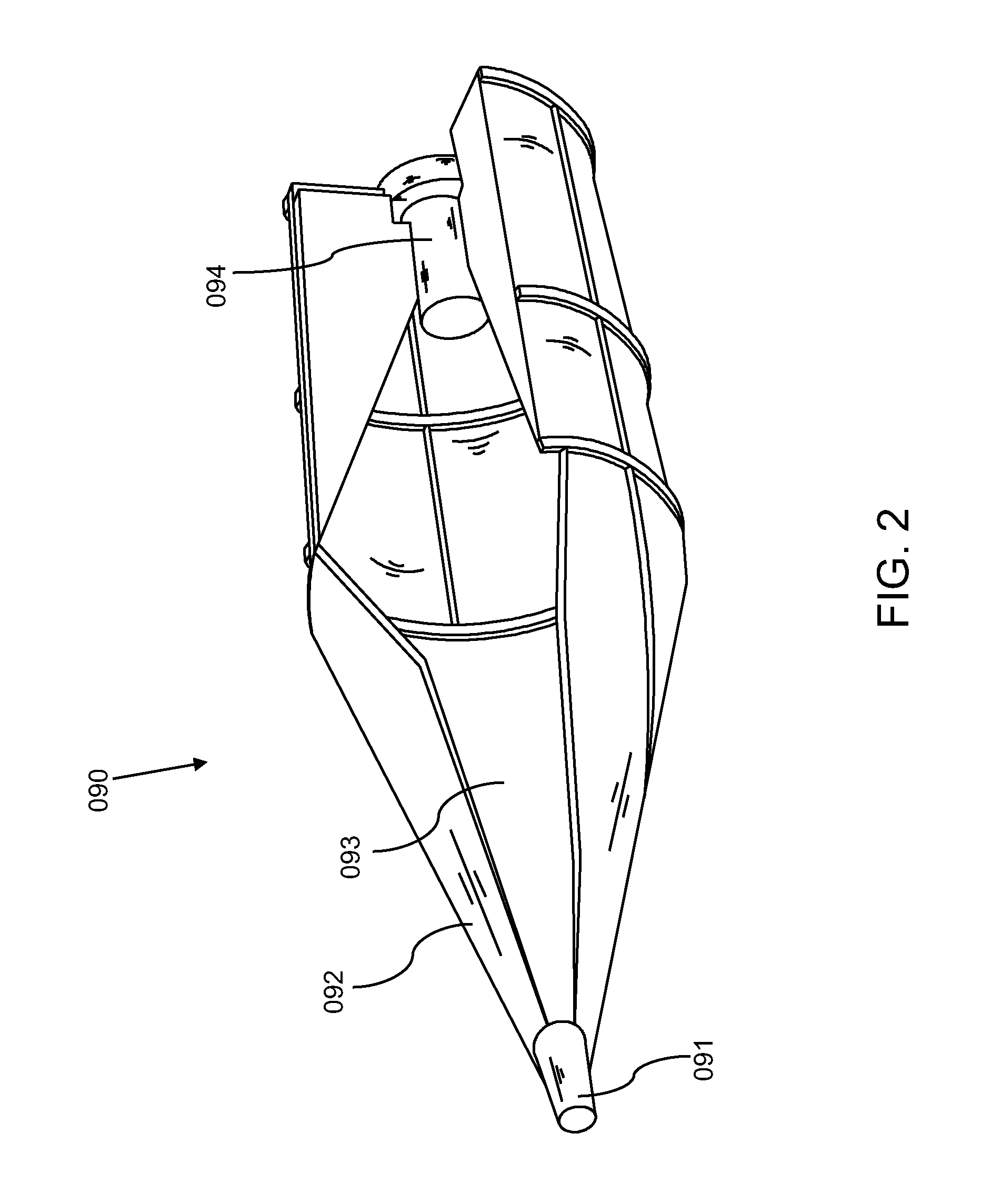

[0022]The bar armor system of the present invention is adapted to minimize damage caused by rocket-propelled grenades (“RPGs”) by reducing the incidence of shaped charges forming upon contact or near-contact with a vehicle sought to be protected. Shaped charges are directionally-oriented explosive detonations (i.e., combustions that propagate via self-sustaining supersonic shock waves) that have the particular effect and highest incidence in causing damage. Shaped charges can be very damaging. Depending on the particular RPG, a shaped charge can penetrate at least 30 cm into armored steel or more. It is unacceptable to attempt to combat shaped charges by simply increasing the thickness of the vehicle armor. The increased thickness would make the vehicle so massive and cumbersome that it could effectively render the vehicle immobile.

[0023]The present invention reduces the need for increased armor thicknesses by substantially reducing the risk of shaped charges causing damage to a tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com