Harvesting micro algae

a technology of micro algae and harvesting techniques, applied in the field of harvesting micro algae, can solve the problems of limited harvesting techniques of microalgae, limited harvesting efficiency of microalgae, and limitations of each present harvesting technique, and achieves low cost, low maintenance, and high concentration factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0064]The presently disclosed γ-Fe2O3@SiO2 composite particles may be well dispersed in solution. FIG. 3A, at left shows a solution of silica coated Fe-oxide nanoparticles in solution. The photo at right in FIG. 3A shows the solution shortly after introduction of an external magnetic field. This figure demonstrates that a homogeneous solution of the present composite particle devices may be rapidly, efficiently, and inexpensively concentrated. The presently disclosed composite particles can be precipitated out of solution rapidly under magnetic field (FIG. 3A). FIG. 3B depicts similar results using Fe3O4 particles.

example 2

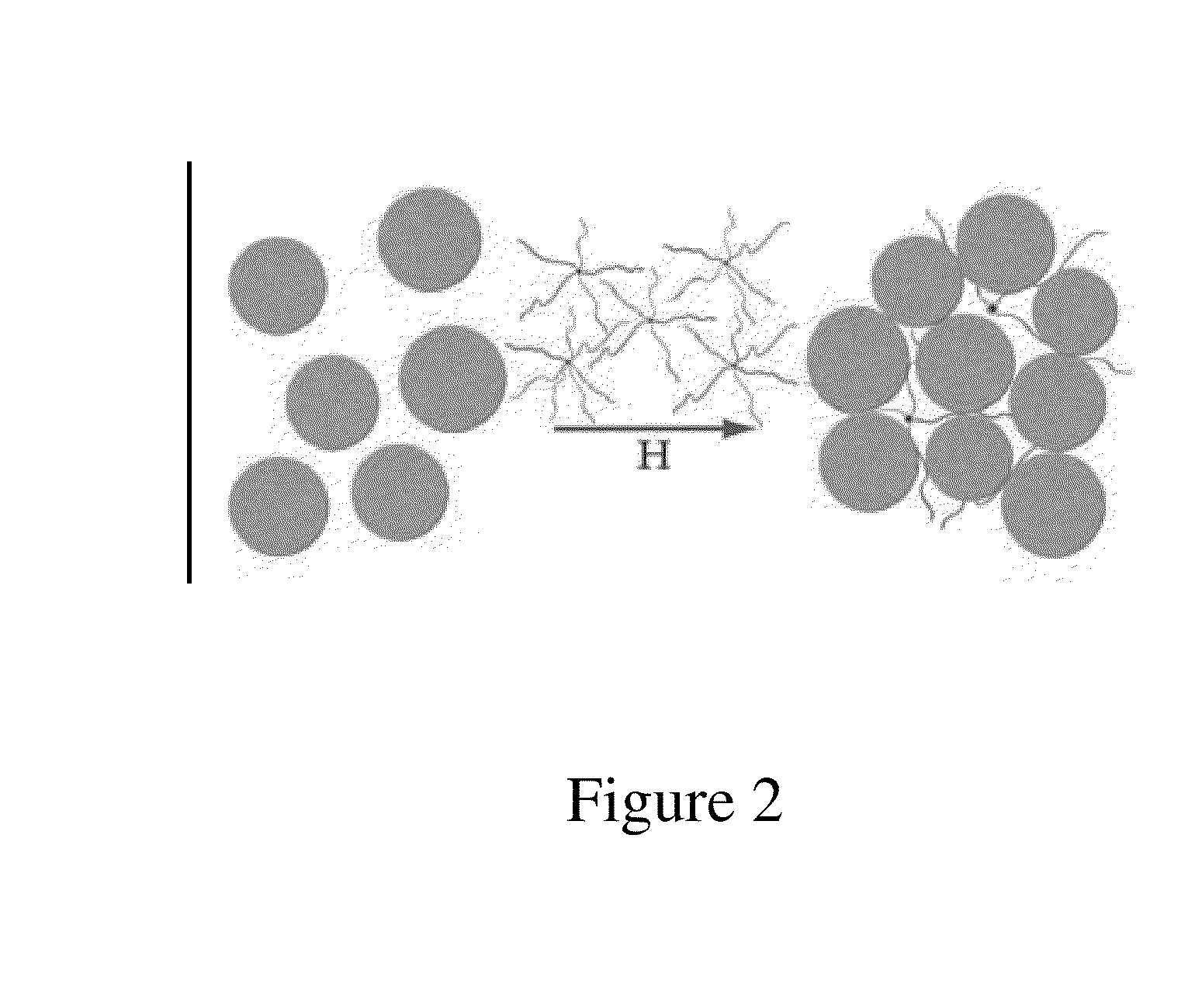

[0065]The presently disclosed γ-Fe2O3@SiO2@Polymer composite particles are used as coagulation agents to rapidly and efficiently concentrate microalgae from growth medium under external magnetic field (H), as schematically depicted in FIG. 2. The composite particles are able to be re-used after microalgae elution or biofuel extraction, thus greatly reduce the cost.

example 3

[0066]Fe3O4@SiO2@Polymer composite particles were used as coagulation agents to rapidly and efficiently concentrate microalgae from a rich algal growth medium. A moderate external magnetic field (H) was provided by a magnetic stirrer bar. The microalgal strain used was Nannochloropsis, which has a small diameter (˜2 μm) and low specific density due to high oil content (˜50% by dry weight). Nannochloropsis is extremely hard to harvest via conventional methods. FIG. 4 shows nearly 100% coagulation of Nannochloropsis occurs in a few seconds after adding a few milligrams of the presently disclosed Fe3O4@SiO2@Polymer composite particles (right: before coagulation; left: after coagulation).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com