Chrome free water-based wellbore fluid

a wellbore fluid, chrome free technology, applied in the direction of fluid removal, wellbore/well accessories, chemistry apparatus and processes, etc., can solve the problems of potential gel formation, fluid loss control is an issue, and fluid loss control becomes a major challenge, and achieve the desired rheological profile and good fluid loss properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

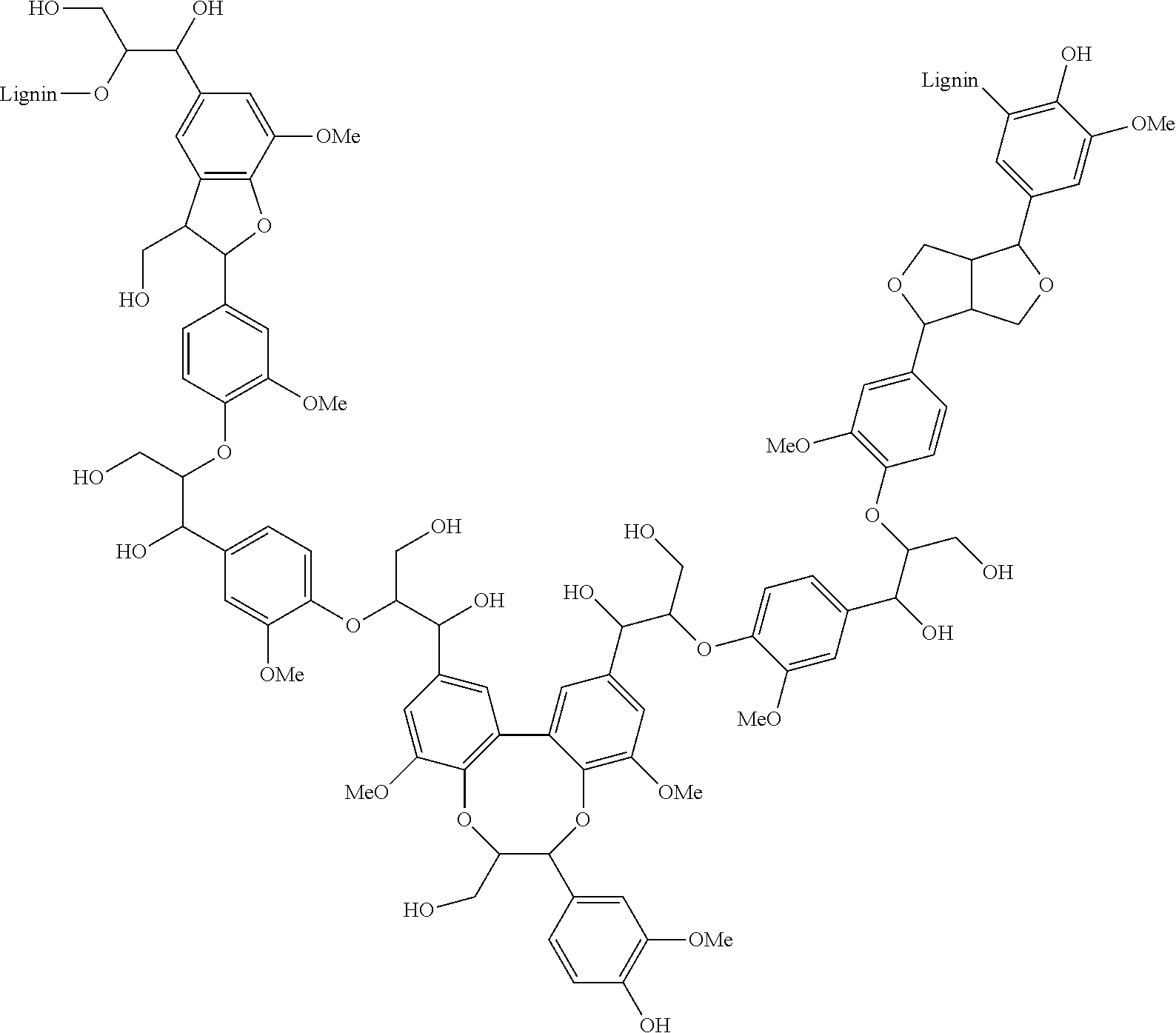

Image

Examples

example 1

[0054]Chrome-free, aqueous-based wellbore fluid A was evaluated for fluid loss control and rheology stability. Wellbore fluid A was formulated as indicated in Table 1, optimized through careful selection of the components for the system, at proper concentration levels of the components. Water was mixed with DUROGEL, a chrome-free sepiolite clay commercially available from M-I L.L.C. Houston, Tex., U.S.A., at the stated concentrations. A chrome-free polyacrylamide, such as Driscal D, commercially available from Drilling Specialties (The Woodlands, Tex., U.S.A.), was included as a chrome-free fluid loss control additive in Fluid A at the indicated concentration. Optimization was achieved with using EMI-1048 as the temperature stabilizer at the indicated concentration. EMI-1048 is a polycarboxylate based temperature stabiliser, commercially available from M-I L.L.C. (Houston, Tex., U.S.A). The concentration of the temperature stabilizer may be in the range of about 1 ppb to about 5 ppb...

example 2

[0057]Fluid B was formulated as indicated in Table 3. EMI-1045 is a chrome-free polyacrylamide fluid loss control additive commercially available from M-I L.L.C. (Houston, Tex., U.S.A.). Dristemp is a synthetic polymer commercially available from Drilling Specialties (The Woodlands, Tex., U.S.A.). The test results are given in table 4.

TABLE 3Formulations using EMI-1045Product / ppbFluid BWater206.8Soda Ash0.25DUROGEL2.0Caustic soda0.5EMI-10453.0RESINEX8.0POLYPAC UL1.0HMP15.0Dristemp0.5Barite500.8PTS 2002.0TANNATHIN10.0SAFESCAVNA0.5Lime1.0

TABLE 4Properties of fluids of Table 3AHR @ 450° F.Fluid B600150300842006010036 66 34PV66YP18pH10.94Gels6 / 22 / 33(10 second / 10minute / 30minute)HTHP @ 350° F.16Static Shear145Strength

[0058]As indicated in Table 4, optimized Fluid B yielded fluid loss less than 20 mL, with a plastic viscosity less than 70 cP. Further, Fluid B provided reduced gelation, with static shear strength less than 200 lb / 100 ft2, and a 10-minute gel of less than 45 lb / 100 ft2.

[0059...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com