Method and device for producing a tubular solid body from a refractory tungsten heavy metal alloy, particularly as a semi-finished product for the production of a penetrator for a kinetic energy projectile with fragmentation effect

a technology of heavy metal alloys and solid bodies, which is applied in the direction of liquid bottling, packaging goods, special packaging, etc., can solve the problems of inconvenient production and high technical cost, and achieve the effect of good fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

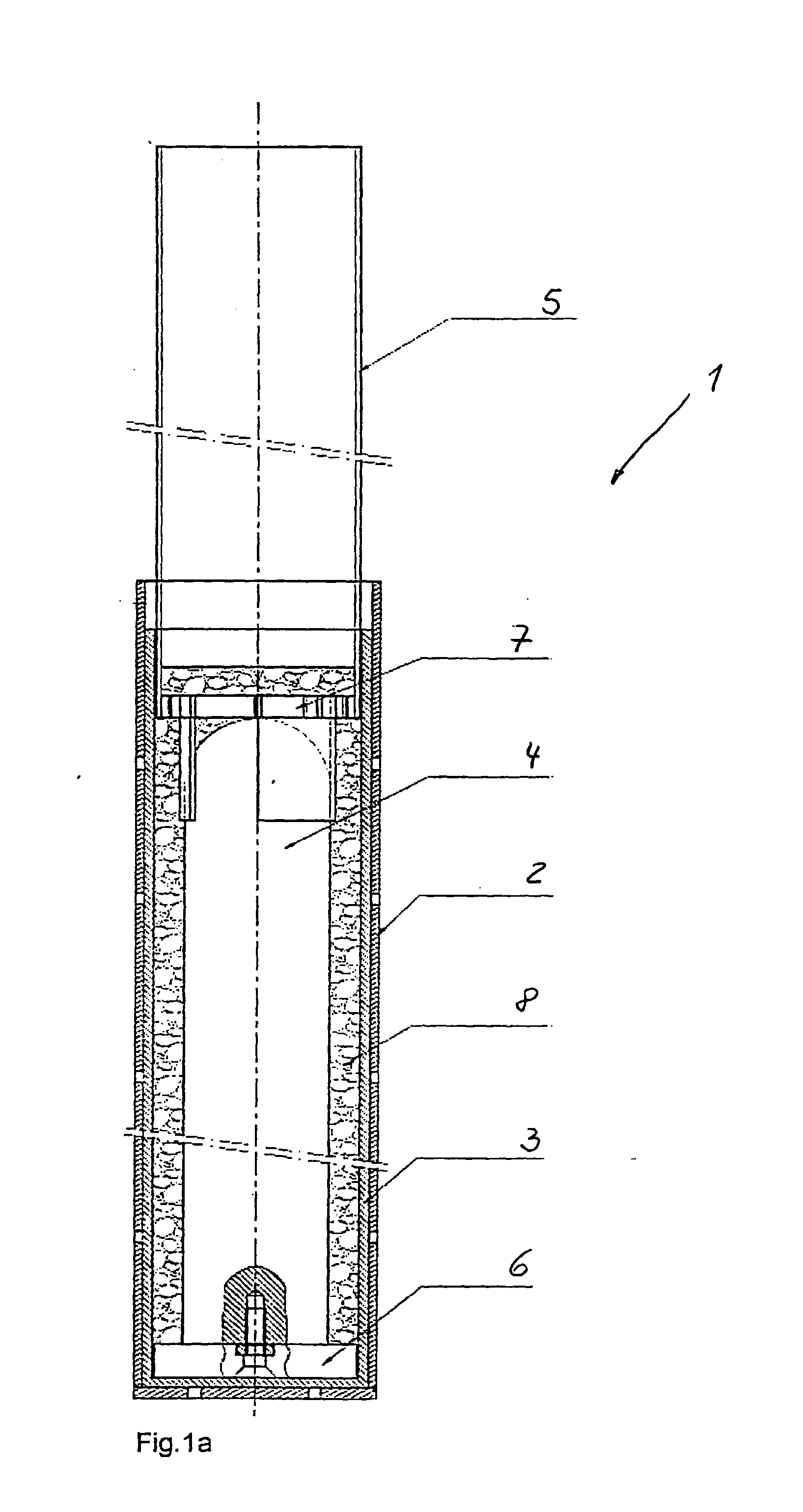

[0021]FIGS. 1a, b show a filler device or filler mold 1 for the production of a tubular solid body 10, here closed on one side (c.f., FIG. 2). The filler device, as shown in FIG. 1a, comprises an outer tube 2 (preferably made of steel), in which bores are situated on the jacket- and base surface at regular intervals. In this outer tube 2, an extrusion die 3 (preferably made of polyurethane), a filler piece 4 (preferably made of metal), and a filler tube 5 are attached concentrically. The concentricity of the filler piece 4 is ensured by a centering disk 6 (preferably made of polyurethane) at the bottom end, and the centering part 7 of the filler tube 5 placed on the filler piece at the top end. The centering part 7 and the filler tube 5 are permanently connected to one another. An intermediate space 8 forming between the extrusion die 3 and filler piece 4 is filled thereby. After the filler device of FIG. 1a has been filled with the metal powder mixture up to the upper end of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inner diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com