Placket straightener

a straightener and placket technology, applied in the field of improved clothing, can solve the problems of wearer discomfort, awkward gestures or body positioning, unusable opening, etc., and achieve the effect of preventing the device from falling out of or off the garment, reducing the separation and increasing the resistance to the opening of the placket panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

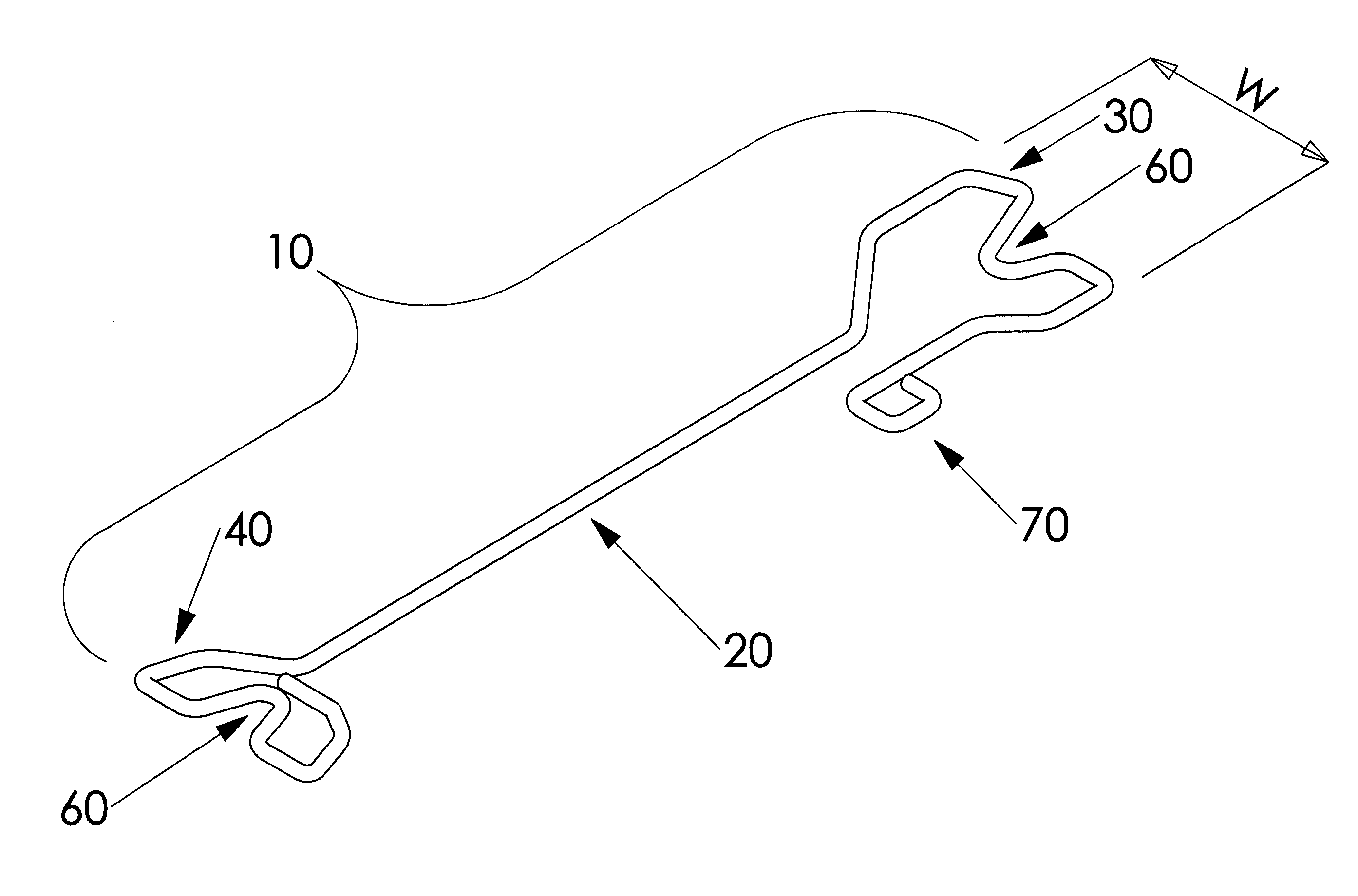

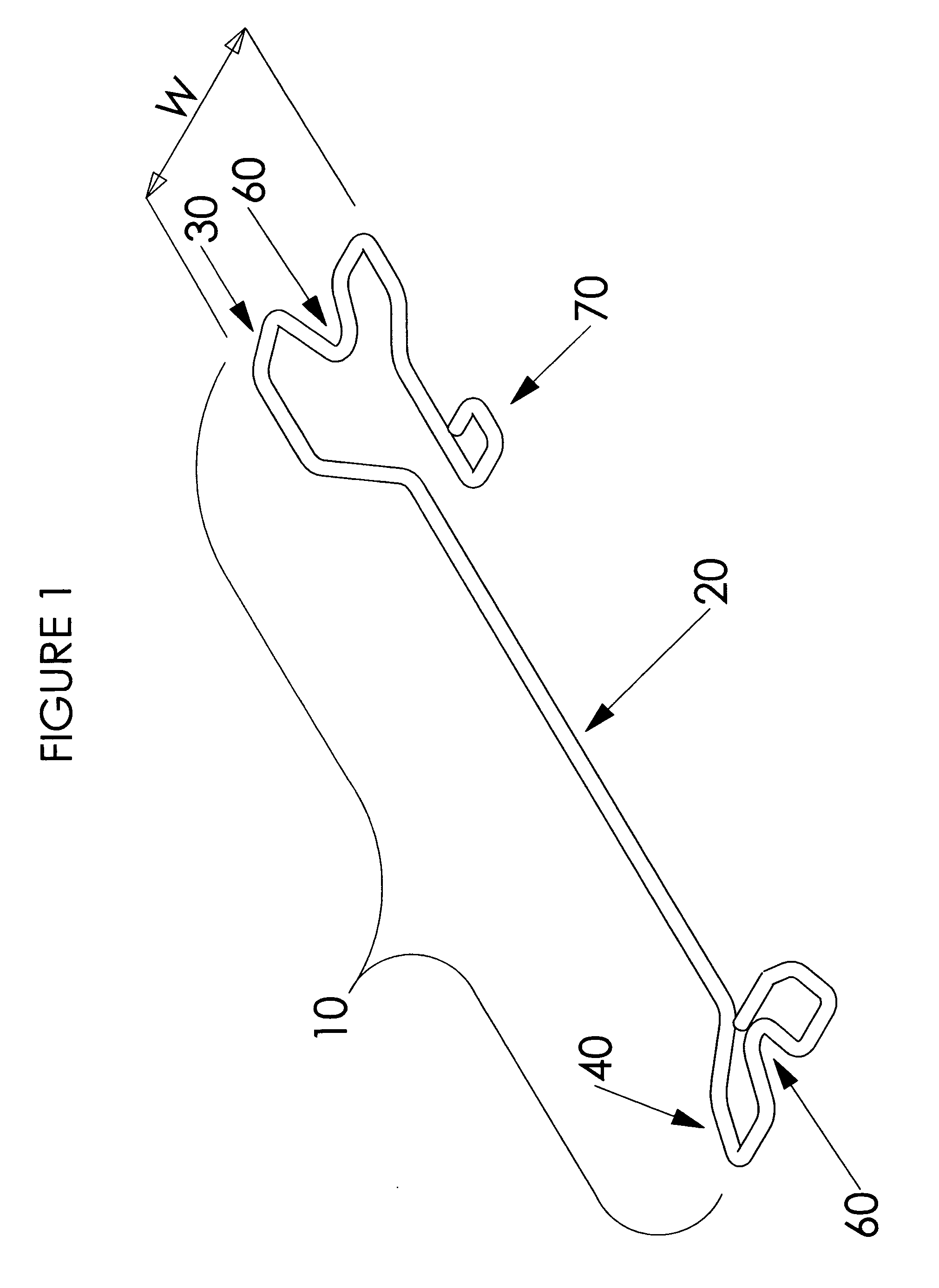

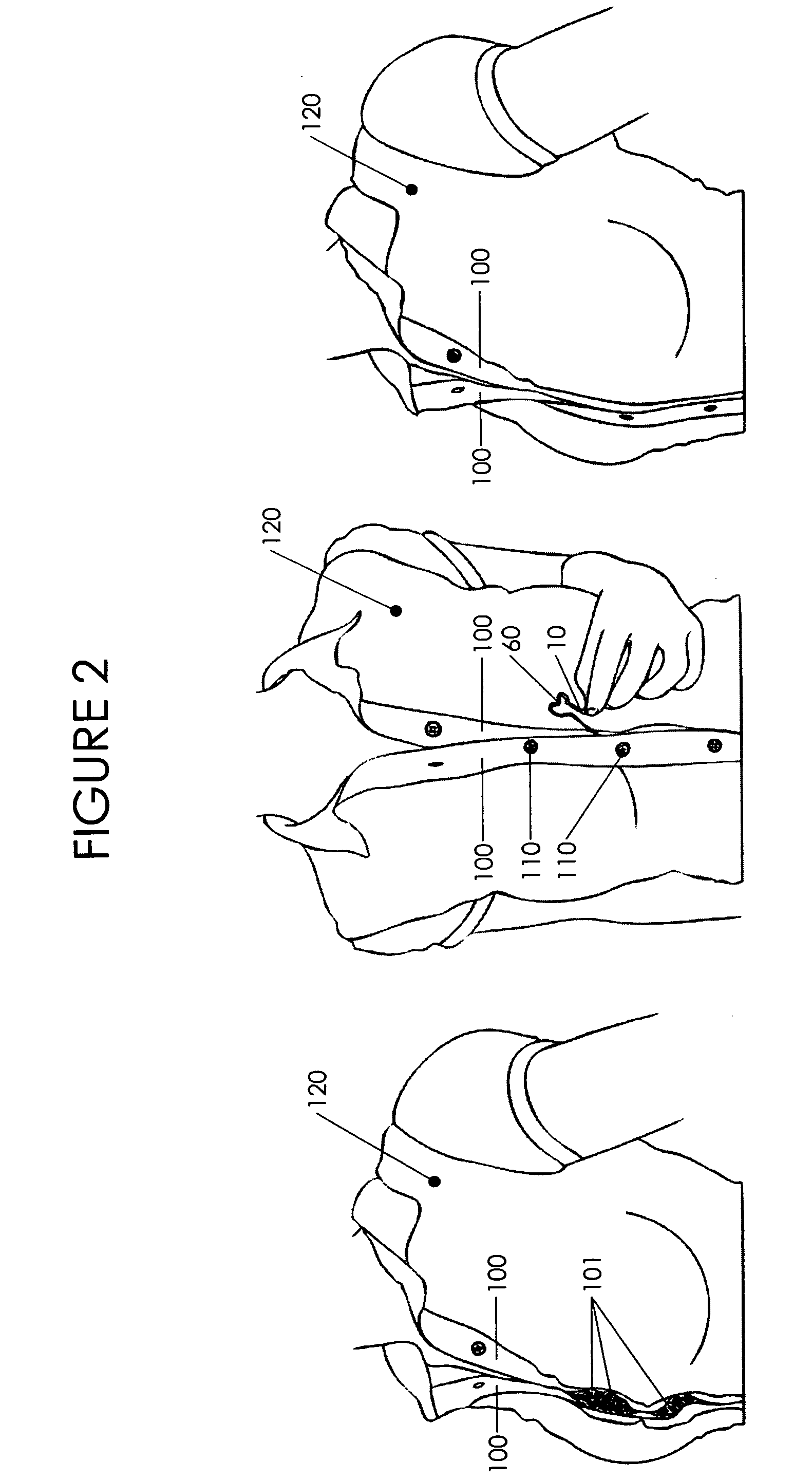

[0045]Referring to the figures, FIG. 1 is one embodiment of a removable placket straightener device shown in accordance with the principles of the present invention. As will be described in greater detail below, the placket straightener 10 is made up of a central component or body 20, in this embodiment shown configured in the shape of wire or tubing (made from one or more of a variety of materials that may include metals and / or plastics), a first end 30 and a second end 40. In the embodiment shown in FIG. 1, the first end 30 and second end 40 are fixedly attached to body 20. As described below for other embodiments, the first end and / or the second end may be removably attached to the body and / or the first end and / or second end may be detachable using a mechanism located on the body. As will be described below for alternative embodiments, the interconnectivity of parts of the device, including the ends, allow for alternative sizes and also for adaptability to different fasteners on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com