High-lethality low collateral damage fragmentation warhead

a fragmentation warhead and high-lethality technology, applied in the field of fragmentation warheads, can solve the problems of increasing the potential for collateral damage without improving the lethality of the warhead, and tight timing tolerances for aimpoint and detonation to engage and destroy the threat while minimizing collateral damage, and achieve the effect of high-lethality low collateral damage fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

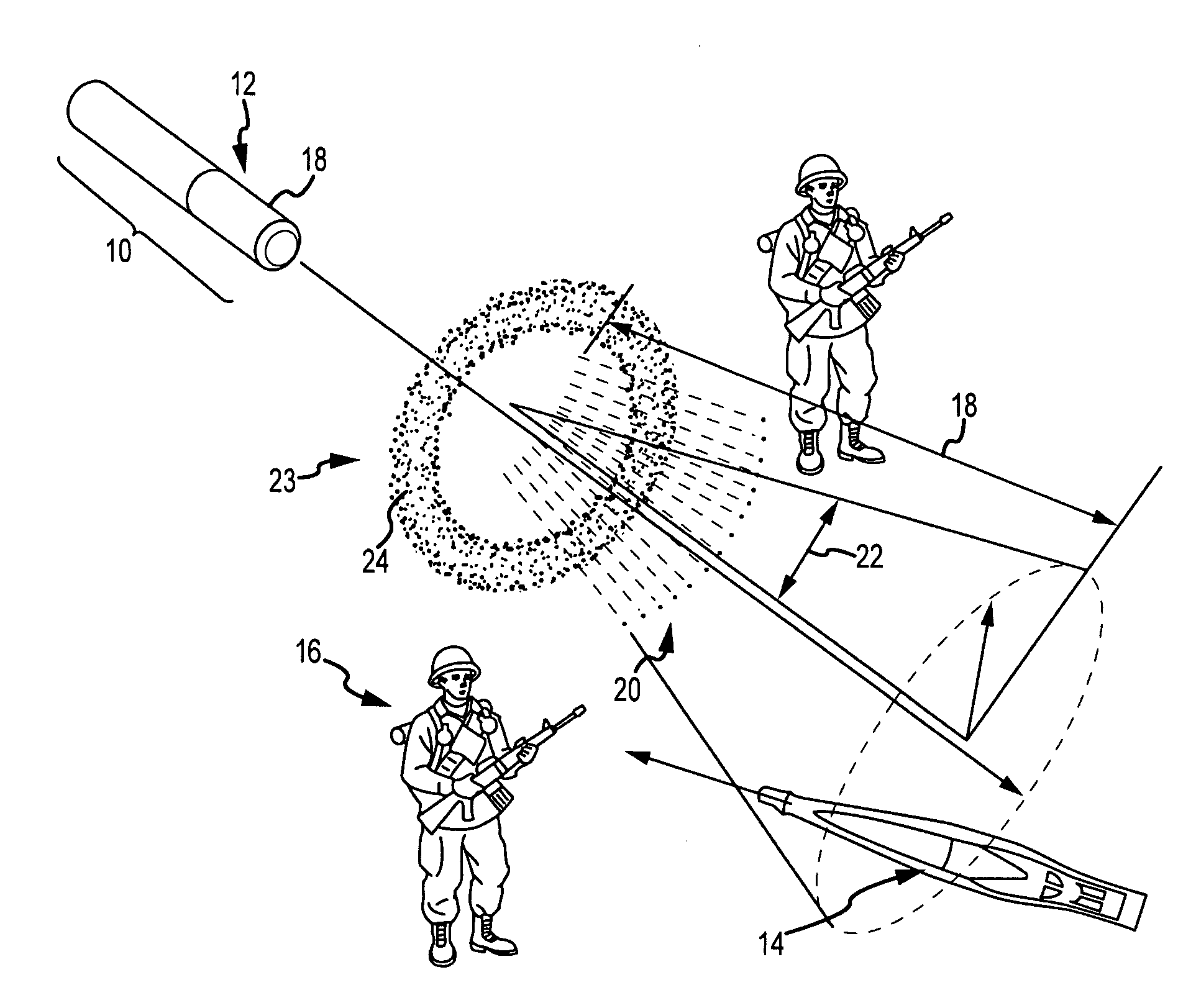

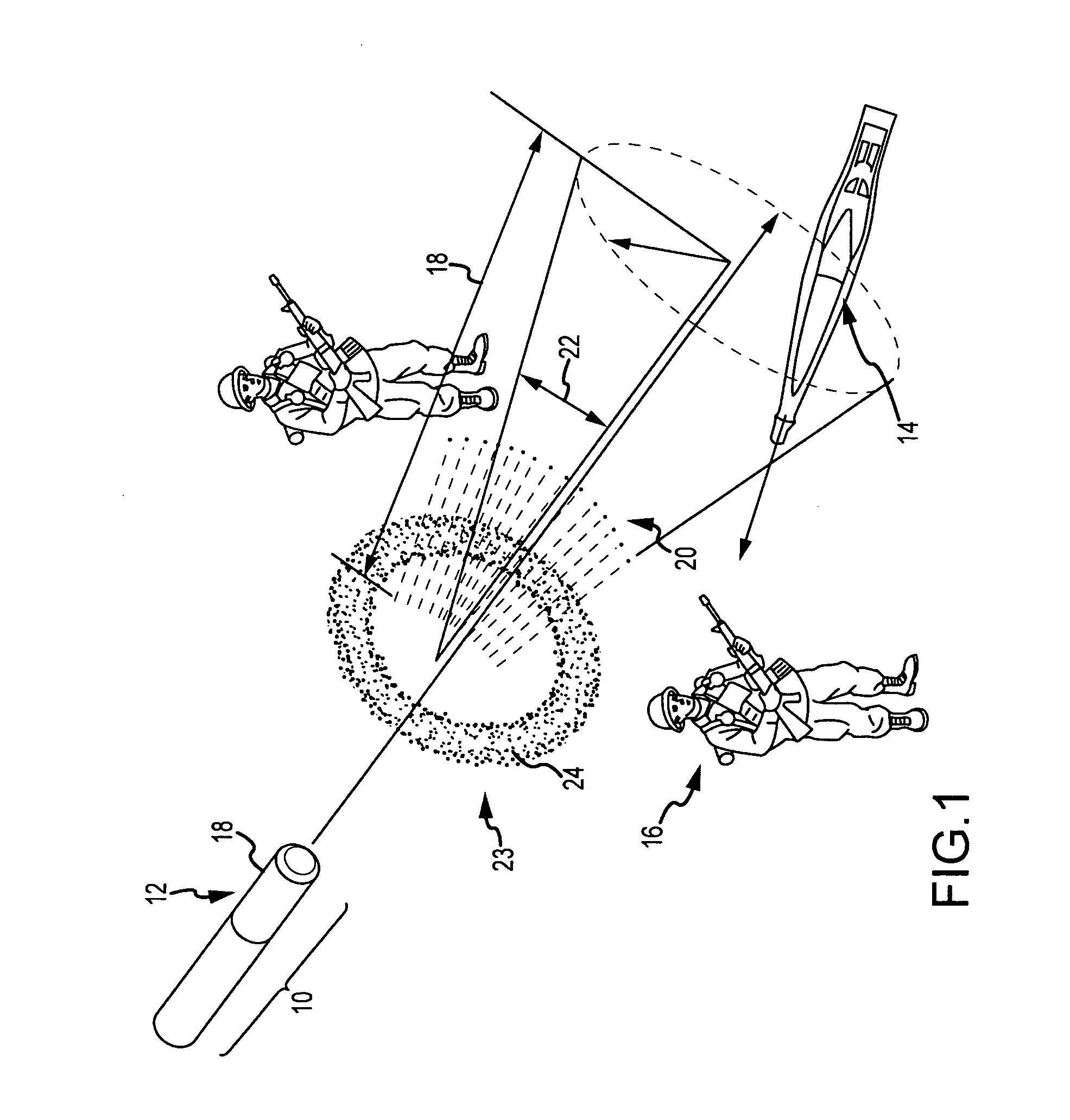

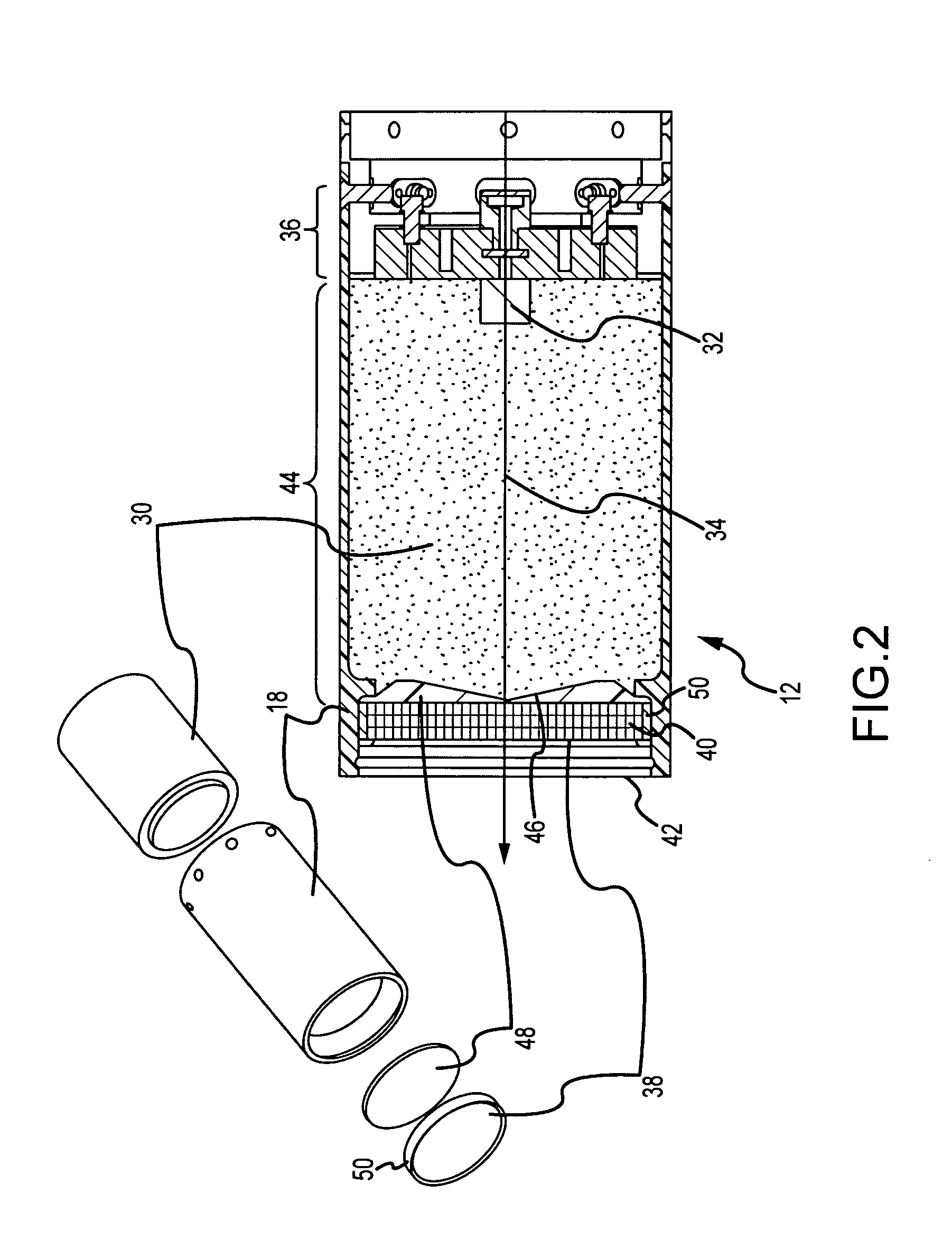

[0021]The present invention provides a high-lethality low collateral damage fragmentation warhead. This is accomplished by forming the case of a material that is pulverized upon detonation of the explosive. As a result, the lethality radius of the pulverized case fragments is no greater than that of the gas blast, thus reducing potential collateral damage. Warhead lethality is improved by placing a pattern shaper between the fragment assembly and the explosive. The explosive and pattern shaper have a conformal non-planar interface that shapes the pressure wavefront caused by detonation of the explosive as it propagates there through to expel metal fragments from the fragmentation assembly with a desired pattern density over a prescribed solid angle.

[0022]The fragmentation warhead can be used in conjunction with a wide range of interceptors including projectiles and self-propelled missiles and spinning or non-spinning and various guidance systems. The aiming and detonation sequence m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com