Apparatus and method for treating ballast water

a ballast water and apparatus technology, applied in the nature of the treatment water, multi-stage water/sewage treatment, separation process, etc., can solve the problems of high cost of use electrodes, easy pollution of electrobath, and destruction of the body of the ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

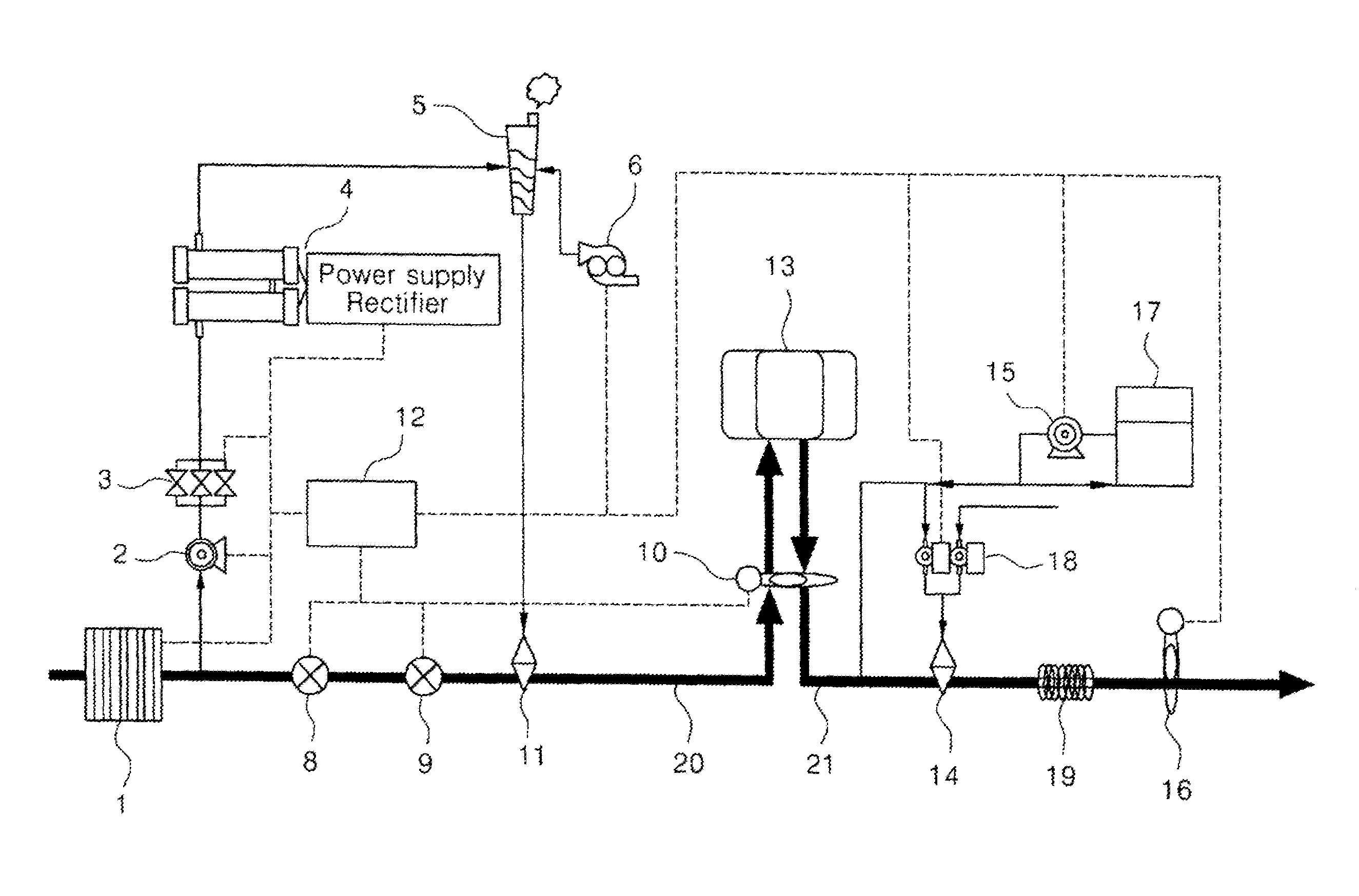

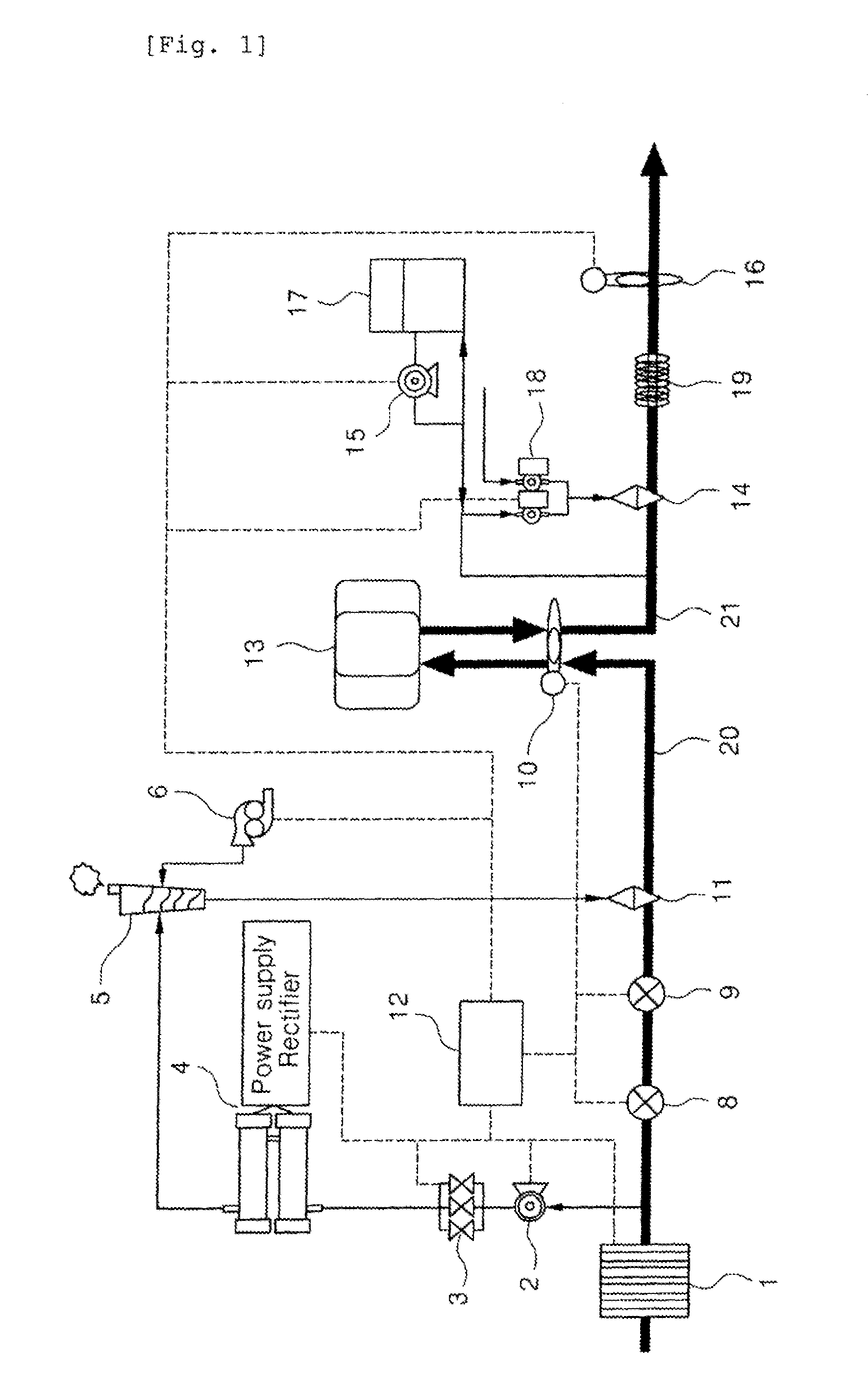

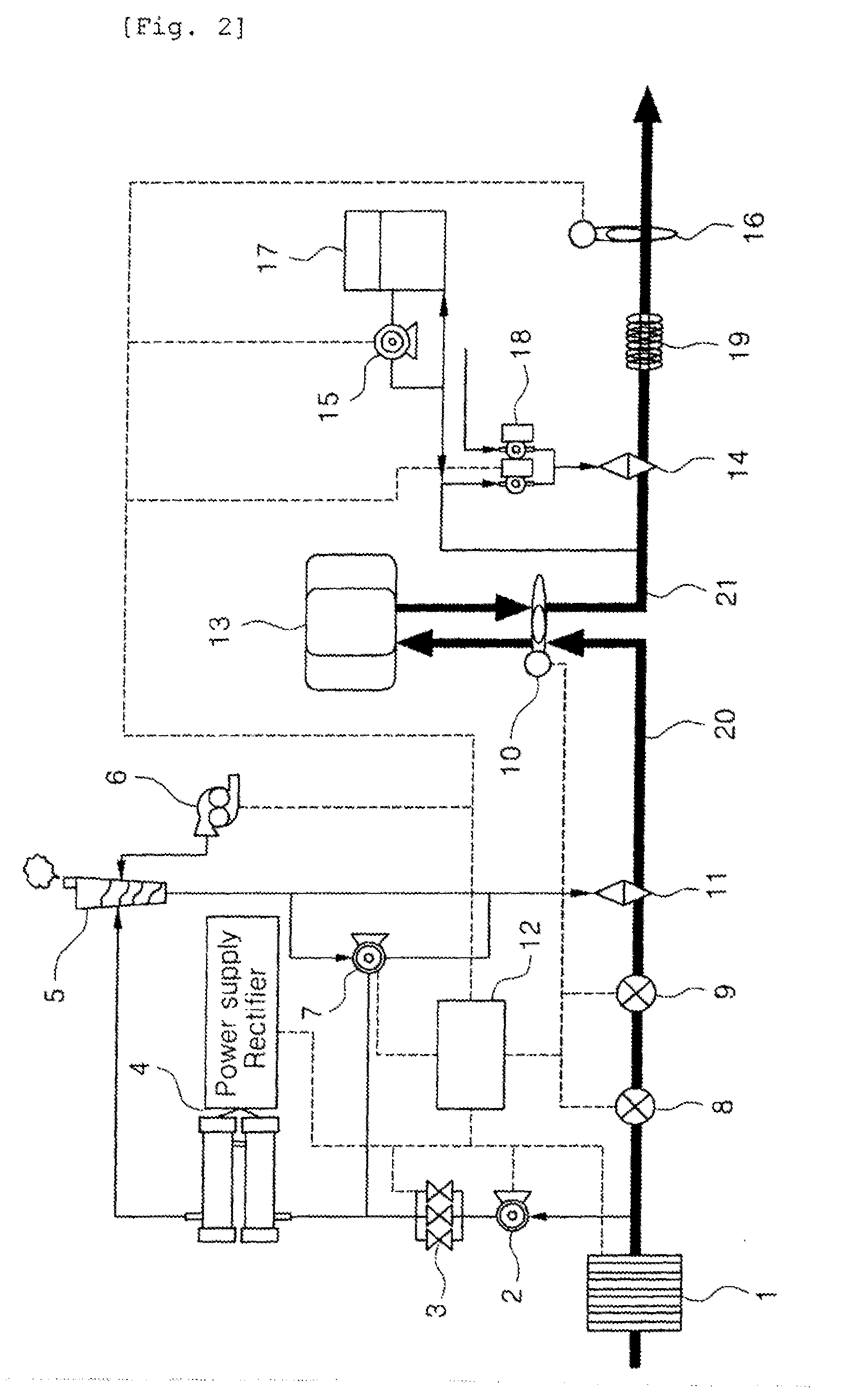

FIG. 2 is a circuit diagram showing a schematic configuration of an apparatus for treating ballast water according to the present invention, wherein most of the configuration thereof is the same as that in FIG. 1. Hereinafter, only components different from those in FIG. 1 will he explained.

According to a second embodiment of the present invention, the apparatus for treating ballast water further includes a cleaning / injection pump 7 connected at one side thereof to the line branched from the sodium hypochlorite supply line between the gas-liquid separator 5 and the automatic injector 11 and connected at the other side thereof to the line branched between the flow rate control valves 3 and the electrolysis module 4, so as to continuously or periodically circulate the sodium hypochlorite passed through the gas-liquid separator 5 to the electrolysis module 4 in which the production of the sodium hypochlorite stops.

If the activation of the electrolysis module 4 stops, the ballast water ...

third embodiment

FIG. 3 is a circuit diagram showing a schematic configuration of an apparatus for treating ballast water according to the present invention, wherein most of the configuration thereof is the same as that in FIG. 1.

According to the third embodiment of the present invention, however, the apparatus is provided at the back portion of the ballast tank 13, and therefore, the residual chlorine measurer 10, as shown in FIG. 1, which is disposed in the seawater intake and discharge lines 20 and 21 at the front and back of the ballast tank 13, is not provided therein. Instead of the formation of the residual chlorine measurer 10, the pre-processing filter 1 as shown in FIG. 1 is disposed in the seawater line at the front of the ballast tank 13, and after the formation of the ballast tank 13, a branch pipe is disposed between the salinometer 8 and the flow rate meter 9 and is connected to the electrolysis module 4 wherein the sodium hypochlorite is produced. Then, the ballast water is passed th...

fourth embodiment

FIG. 4 is a circuit diagram showing a schematic configuration of an apparatus for treating ballast water according to the present invention, wherein since the basic configuration and operating principles thereof are the same as those in FIG. 2, and an explanation on them will be avoided.

FIG. 5 is a circuit diagram showing a schematic configuration of an apparatus for treating ballast water according to a fifth embodiment of the present invention, wherein the basic configuration thereof is the same as that in FIG. 1, except that the seawater used to produce the sodium hypochlorite is not supplied from the seawater intake line 20 flowing to the ballast tank 13 but supplied selectively from a cooling seawater line before heat exchange 22 and from a cooling seawater line after heat exchange 23.

Generally, the seawater used for other proposes as well as the ballast water exist in the ship. That is, when various equipment and an engine in the ship are cooled, freshwater is used for direct ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com