Pet containers with enhanced thermal properties

a technology of thermal properties and enhanced containers, applied in the direction of transportation and packaging, rigid containers, other domestic articles, etc., can solve the problem of all peak shifts by the same amount, and achieve enhanced thermal stability, enhanced thermal properties, and enhanced thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

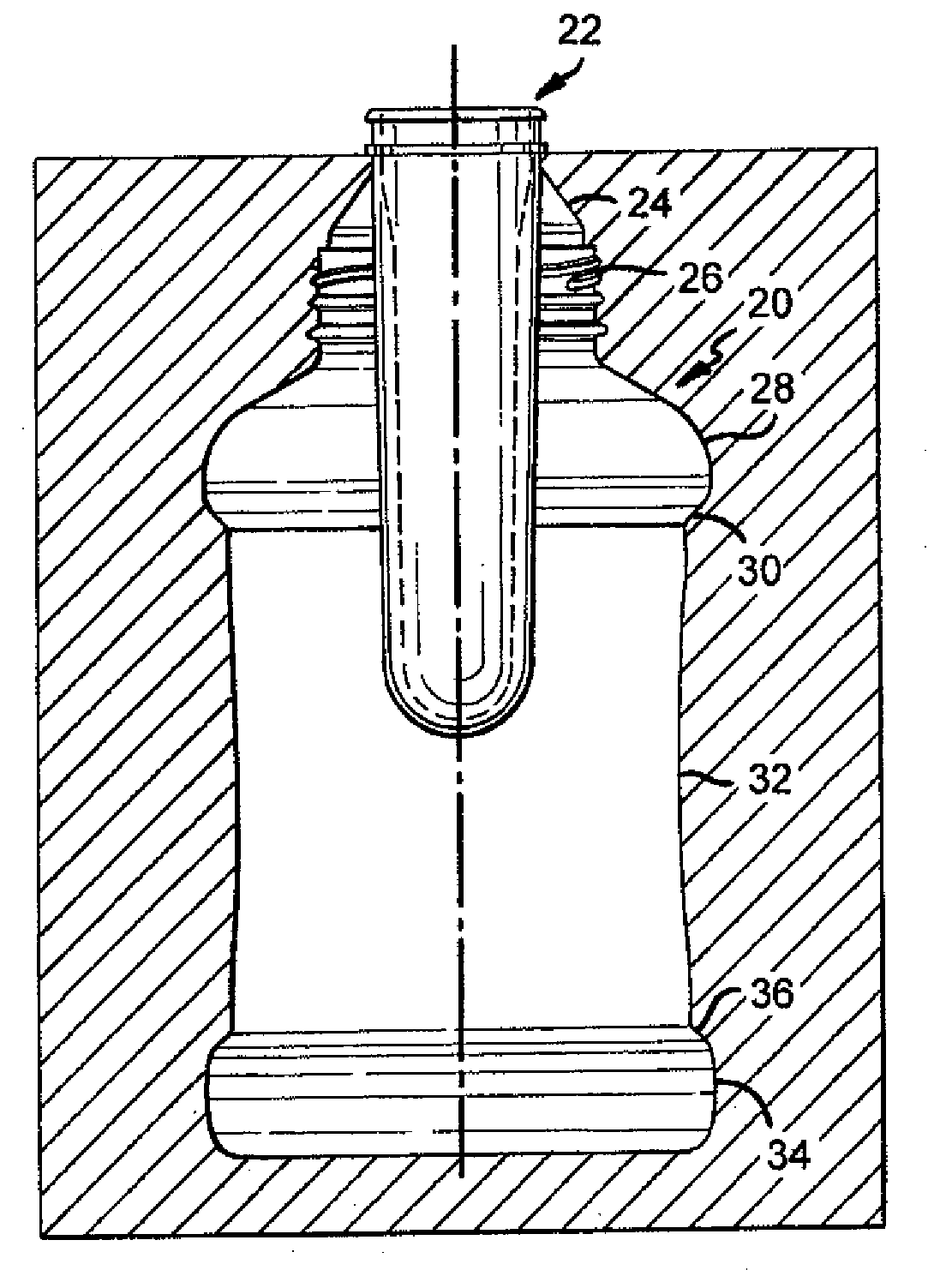

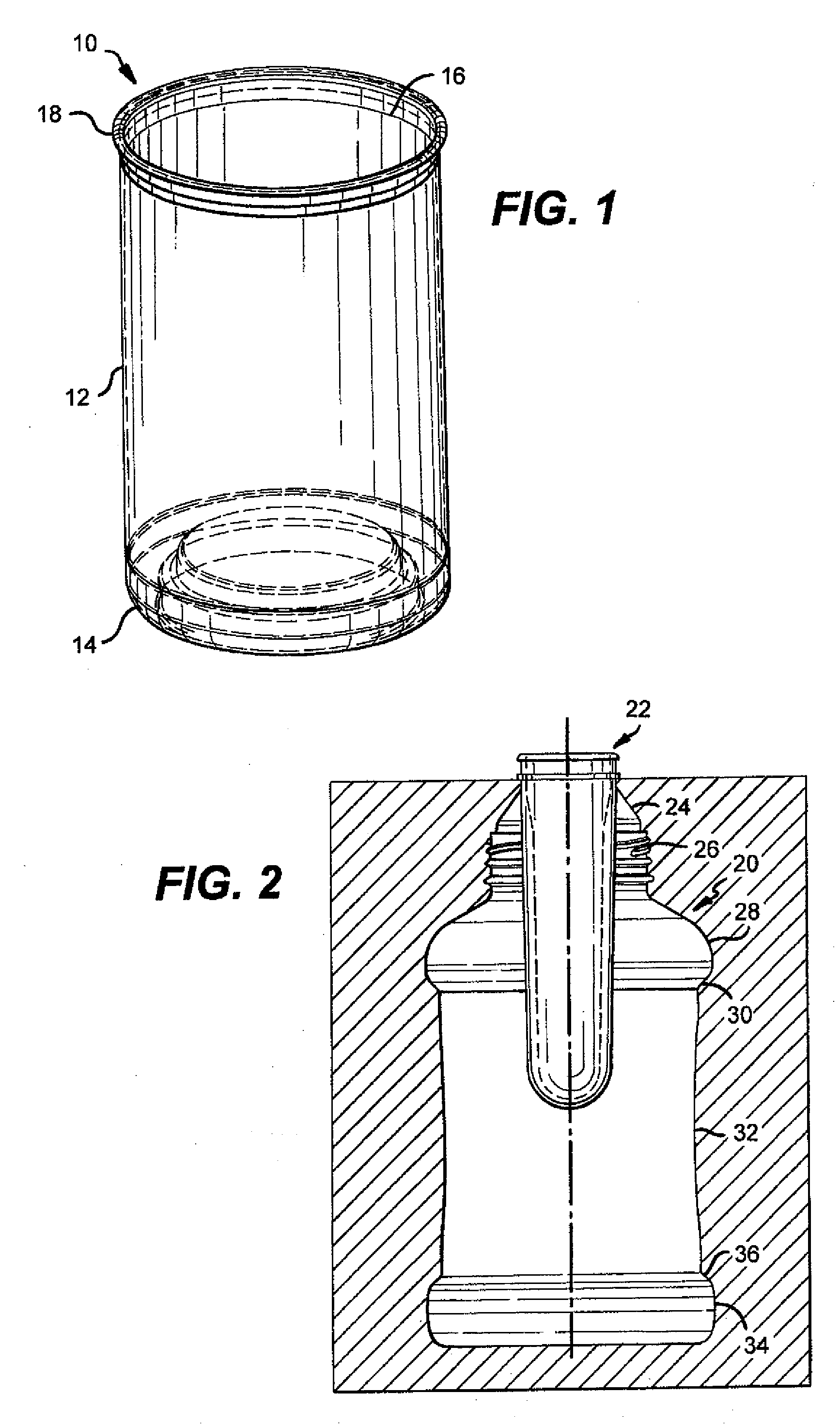

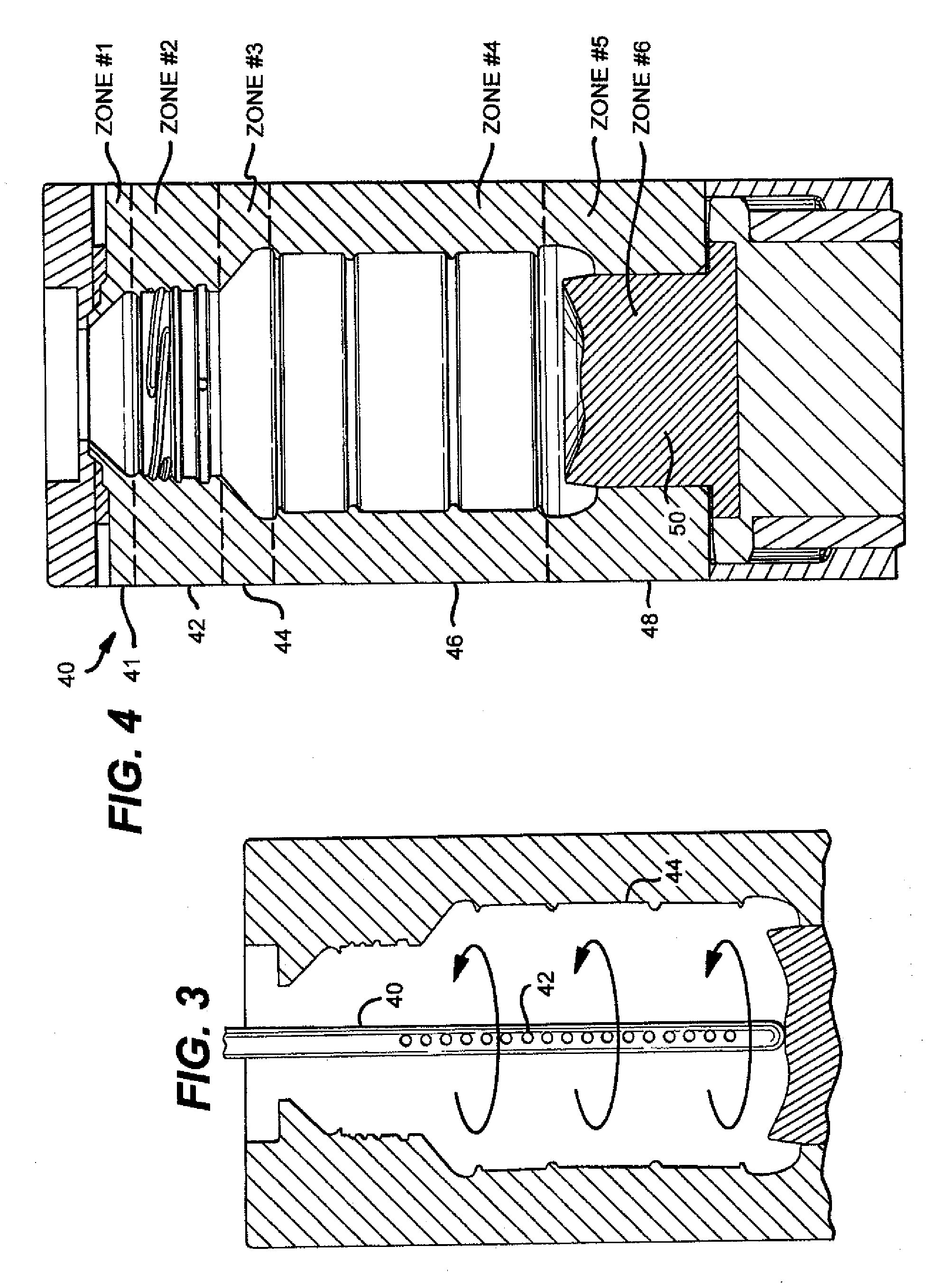

[0036]While this invention is susceptible of embodiment in many different forms, there is shown in the drawings, and will be described herein in detail, specific embodiments thereof with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the invention to the specific embodiments illustrated.

[0037]The present invention provides a container of a crystallizable polymer having enhanced thermal properties while still providing a container with high clarity. Suitable crystallizable polymers include, for example, homopolymers of poly (ethylene terephthalate) and phthalic based copolymers (“PET”). In a preferred form of the invention, the containers will be fabricated from PET resin having an intrinsic viscosity from 0.72 to about 0.86. Suitable PET resins include bottle grade PET resins including PARASTAR resins sold by the Eastman Chemical Company, PET resins sold by Wellman, Inc. and CLEA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| second endothermic transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com