Fluid flow conditioner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

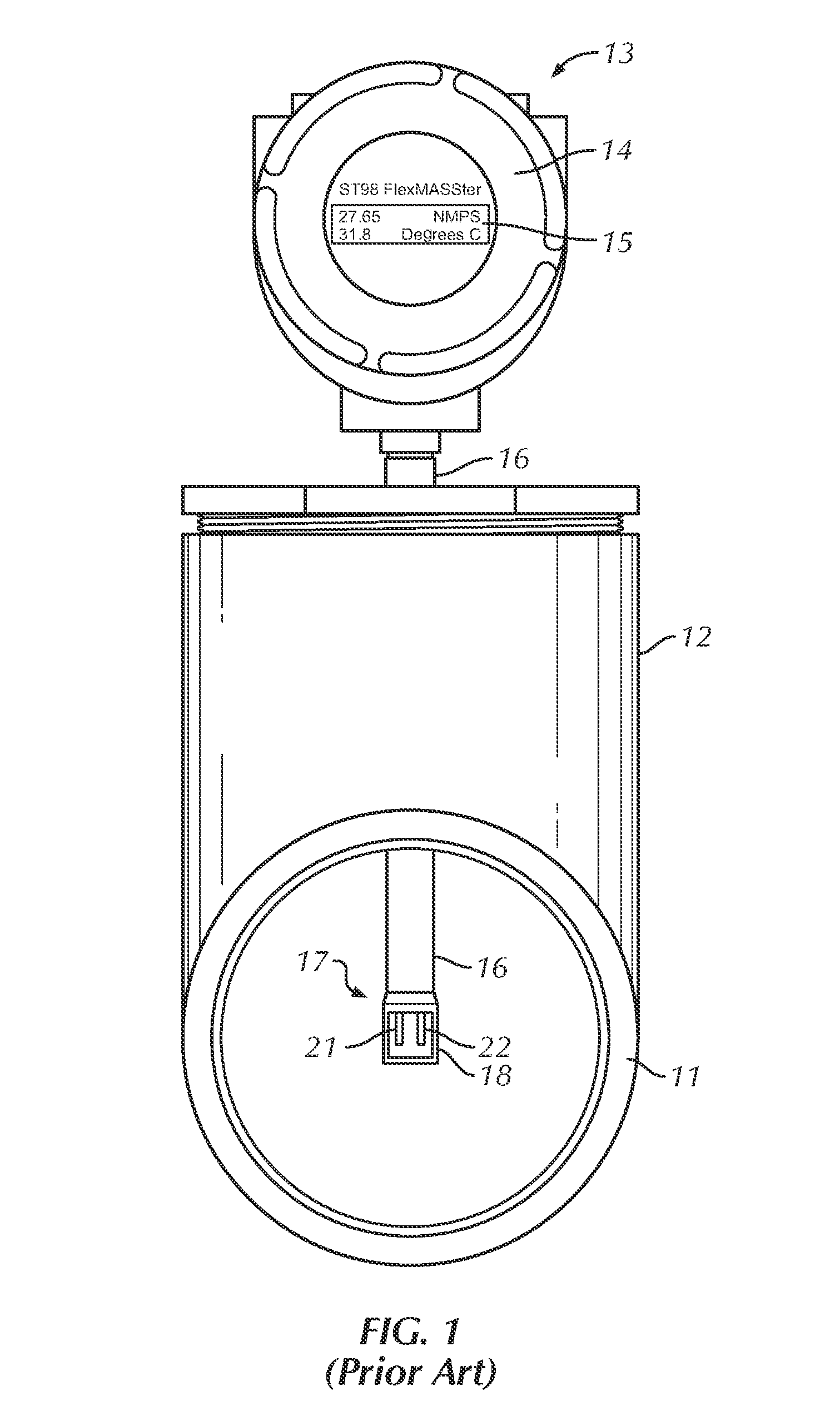

[0023]According to various embodiments for flow conditioning, the media that flows within a conduit can be either a gaseous or a liquid substance, so the term “fluid” may be used to include both. Therefore, the embodiments described herein should not be seen as limiting and the scope of the invention should be measured as defined by the appended claims. These embodiments generally describe gaseous media flowing within a conduit, but it should be understood that liquid embodiments are also envisioned. Also, the metering systems illustrated in these embodiments are generally thermal flow meters to measure flow of media within a conduit using transducer elements and it should be understood that other measuring elements can also be used with the flow conditioners described herein. Any type of thermal flow metering system may be employed, including differential temperature, differential power, and differential current, for example. It is also envisioned that alterations may be made to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com