Priming mix

a technology of priming mix and priming compound, which is applied in the direction of looms, explosives, textiles and papermaking, etc., can solve the problems of increasing the reactivity of the priming mix that is neither sufficient nor desirable, and the incidence of accidental firing of the cartridge or shell increases, so as to improve the balance sensitivity, stability, and other desirable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

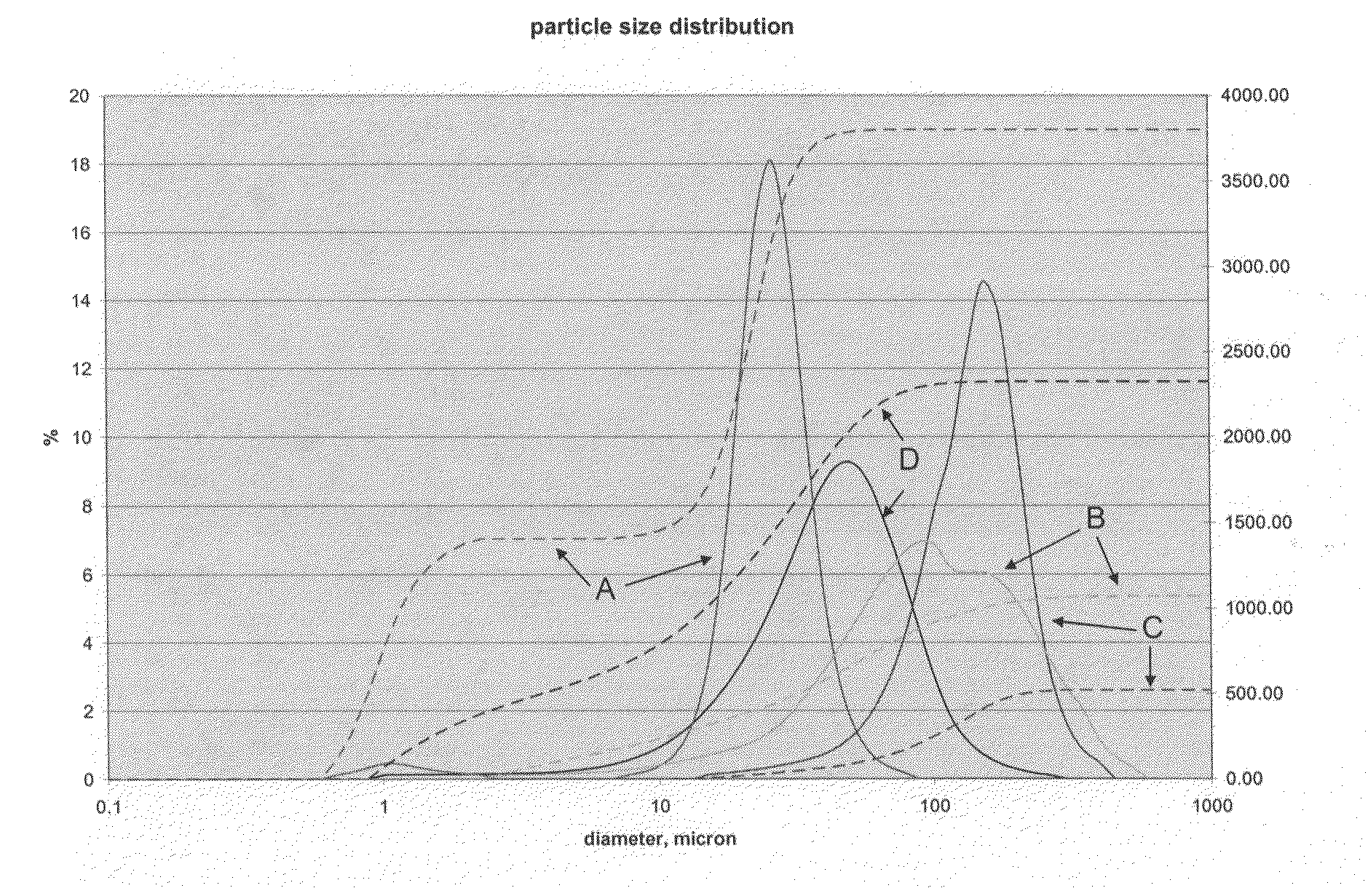

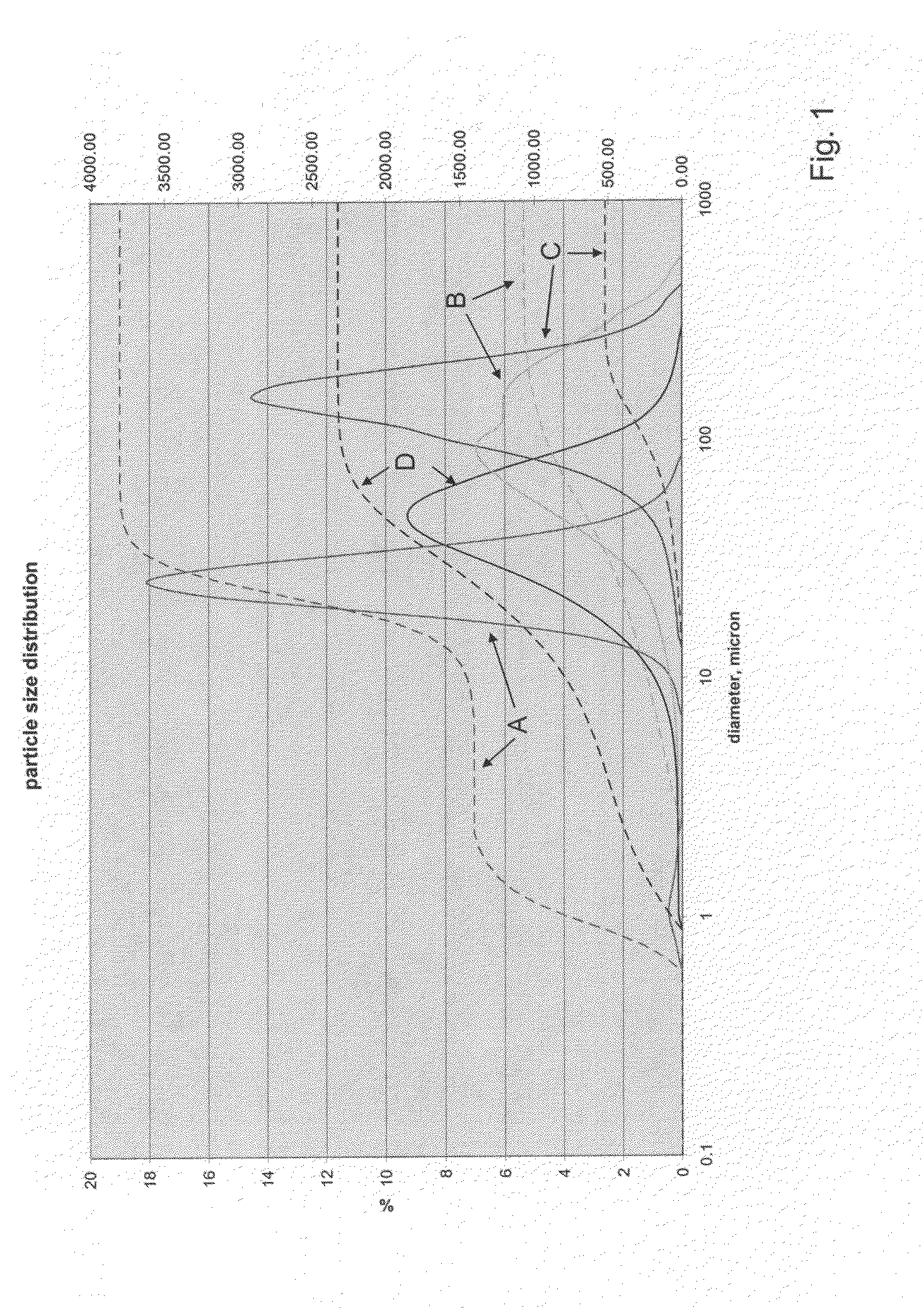

Image

Examples

example 1

[0027]In a first preferred embodiment, a priming mix is made with from 30% to 40% lead styphenate, 2% to 6% tetrazene, 0% to 6% PETN, 3% to 8% superfines; 2% to 5% aluminum, and 35% to 55% Ba(NO3)2. More specifically, an exemplary priming mix was made with about 35% lead styphenate, about 5% tetrazene, about 3% PETN, about 5% propellant superfines, about 3% aluminum, and about 50% Ba(NO3)2.

[0028]More specifically, an exemplary composition of a priming mix and a control of the compositions shown in Table 1 were prepared, and tested in three sets of steel die drop tests. The results of which are reported in Table 2.

[0029]As shown in Table 2, the performance of the exemplary composition is superior at 5″, where there was at least one misfire out of fifty for the control in each set compared to no misfire for the exemplary composition; at 4″, where there was at least eight and as many as eighteen misfires out of fifty for the control in each set, compared to a maximum of four misfires o...

example 2

[0030]A primer composition was prepared with the following composition:[0031]35% KDNBF[0032]4% Tetrazene[0033]5% superfines[0034]15% iron sulfide (ferrous sulfide) FeS[0035]41% Potassium Nitrate KNO3

example 3

[0036]A primer composition was prepared with the following composition:[0037]42% KDNBF[0038]6% Tetrazene[0039]8% superfines[0040]7% Boron[0041]37% Potassium Nitrate KNO3

PUM

| Property | Measurement | Unit |

|---|---|---|

| median diameter | aaaaa | aaaaa |

| median diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com