Method and apparatus for carrying out nickel and hydrogen exothermal reaction

a hydrogen exothermal reaction and nickel technology, applied in lighting and heating equipment, nuclear reactors, greenhouse gas reduction, etc., can solve the problems of not providing useful and reliable systems capable of generating energy for normal, industrial or domestic applications, and reducing the risk of persons living near radioactive waste disposal off places. achieve the effect of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

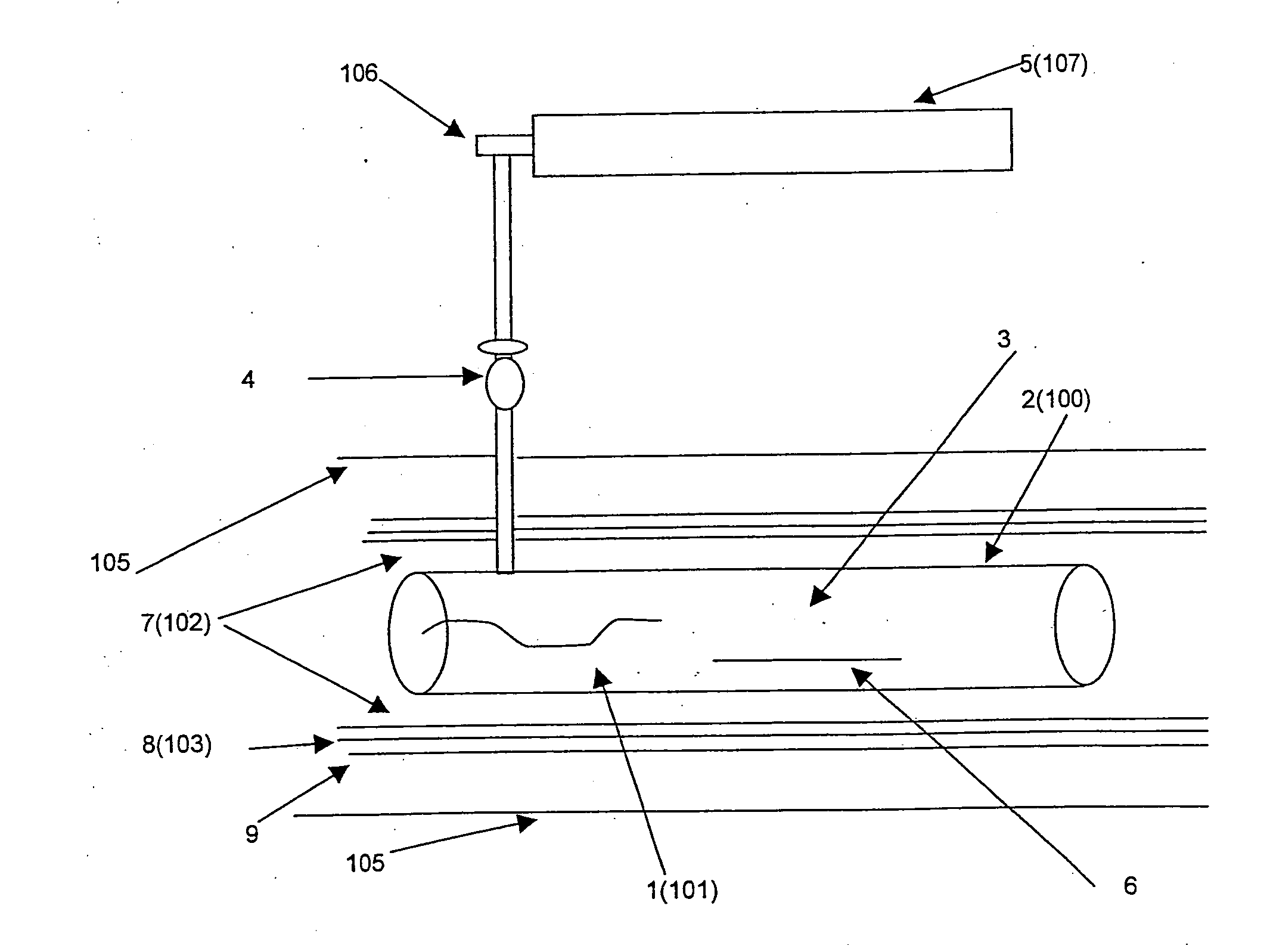

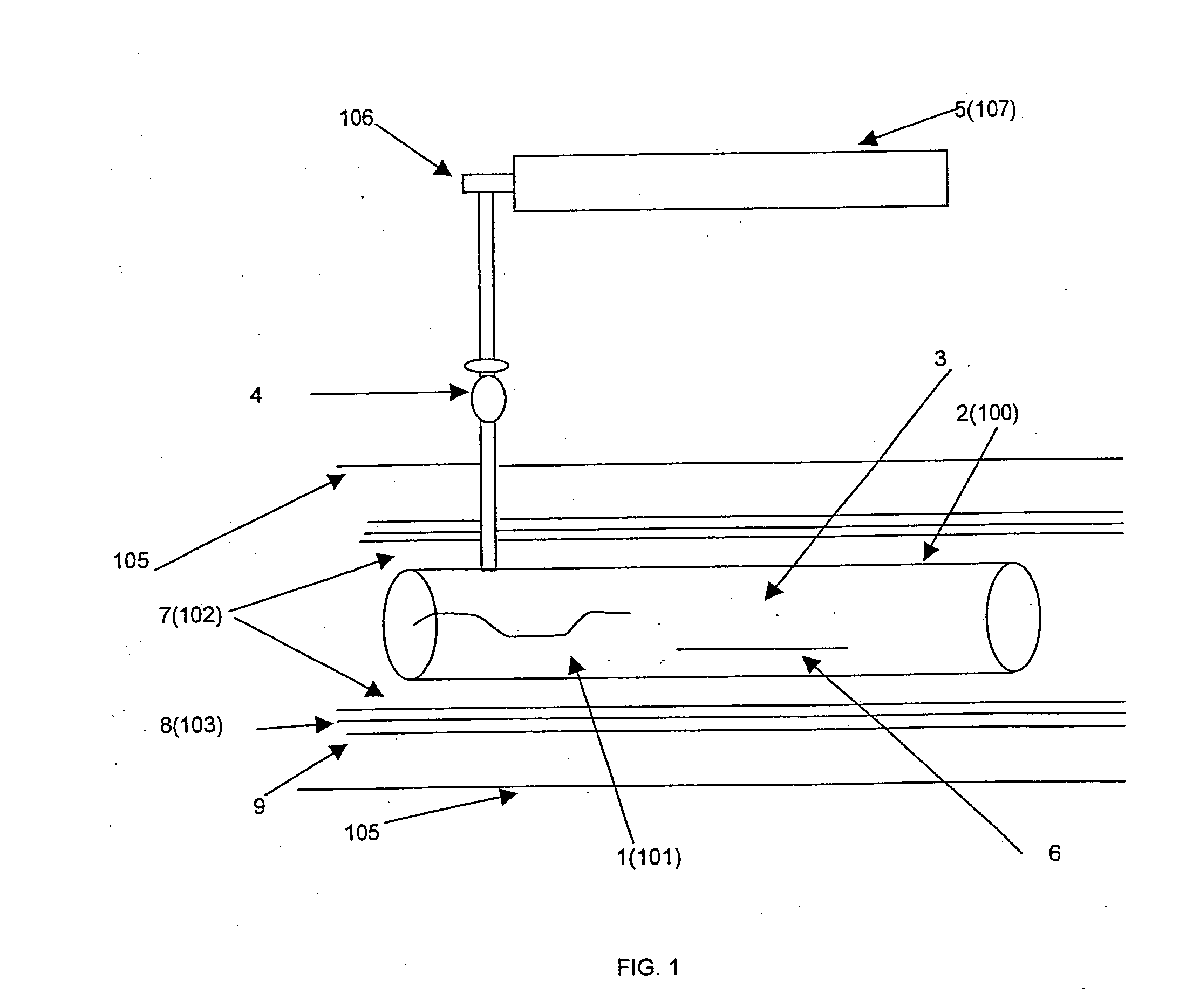

With reference to the number references of the above mentioned figures, the apparatus according to the present invention comprises an electric resistance 1, enclosed in a metal tube 2, further including therein a nickel powder 3.

A solenoid valve 4 adjusts the pressure under which hydrogen 5 is introduced into the metal tube.

Both the temperature generated by the electric resistance or resistor and the hydrogen injection pressure can be easily adjusted either to constant or pulsating values.

More specifically, the electric resistance, or other heat source, is switched off as the exothermal reaction generating energizing status is triggered. A thermostat will hold said heat source operating, depending on the temperature in the circuit.

The assembly comprising said electric resistance and nickel holding copper tube is shielded from the outer environment by using, respectively from the inside to the outside:

a) a jacket 7 including water and boron, or only boron

b) a further lead jacket 8, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com