Container of the type comprising a receptacle and a hinged lid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

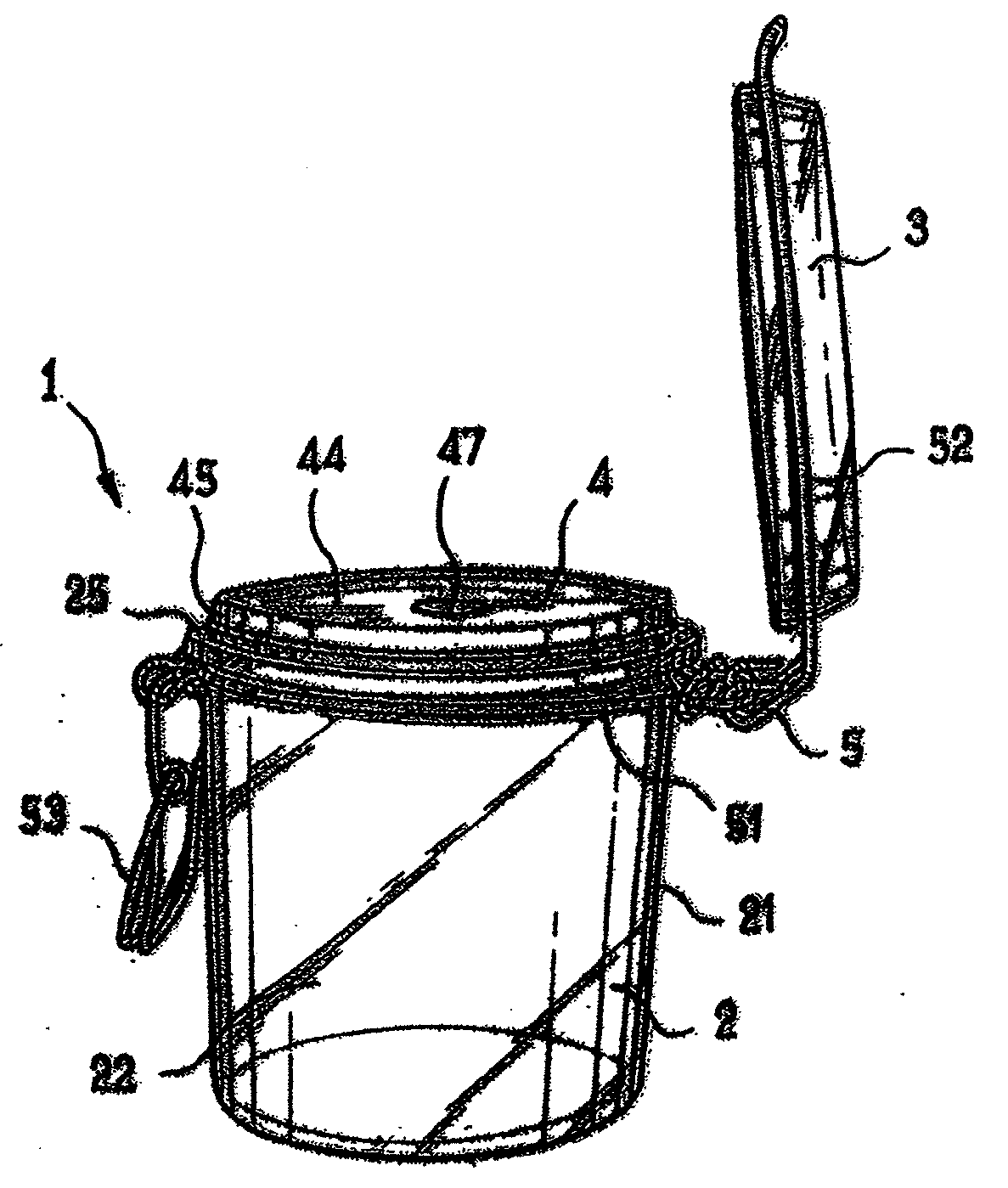

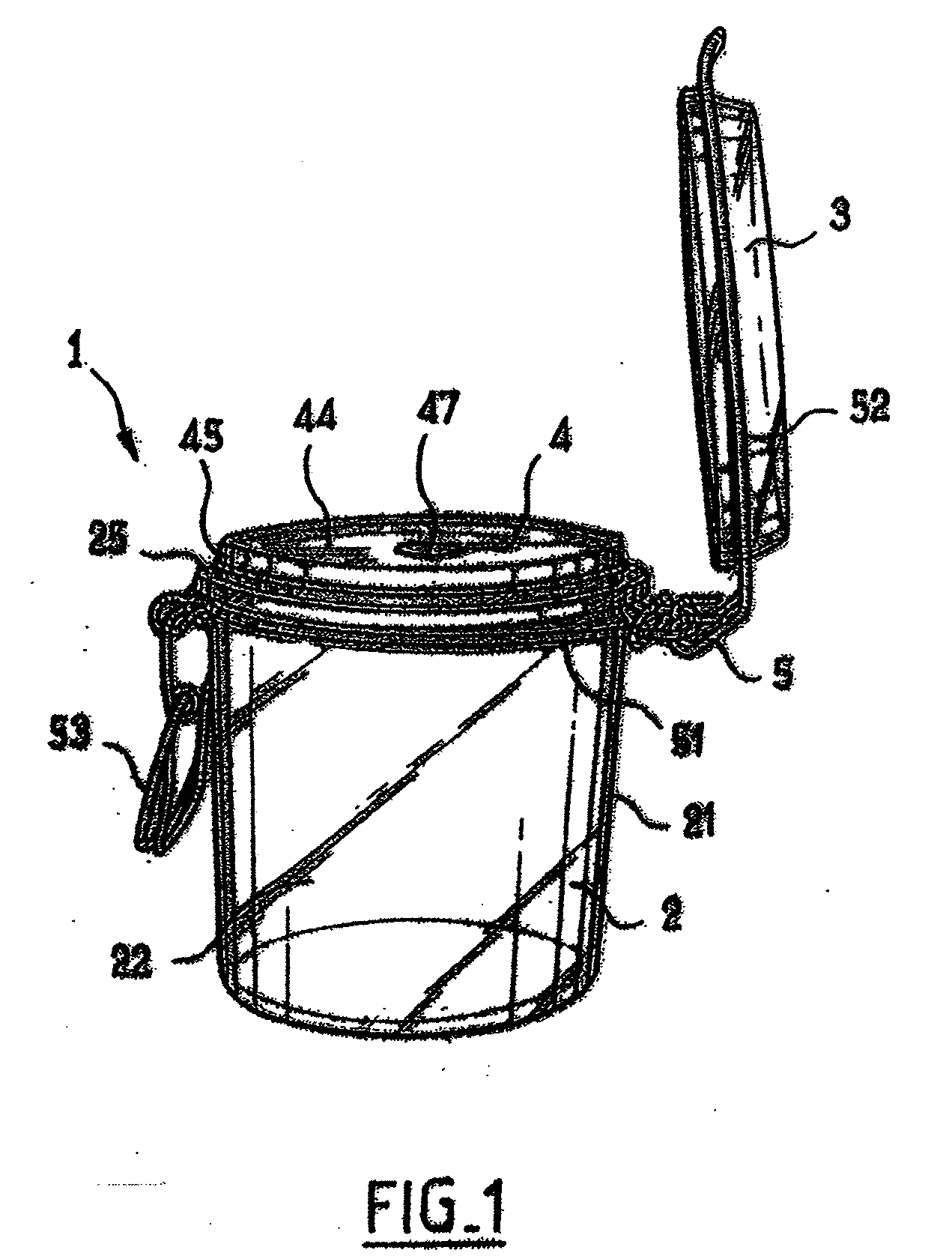

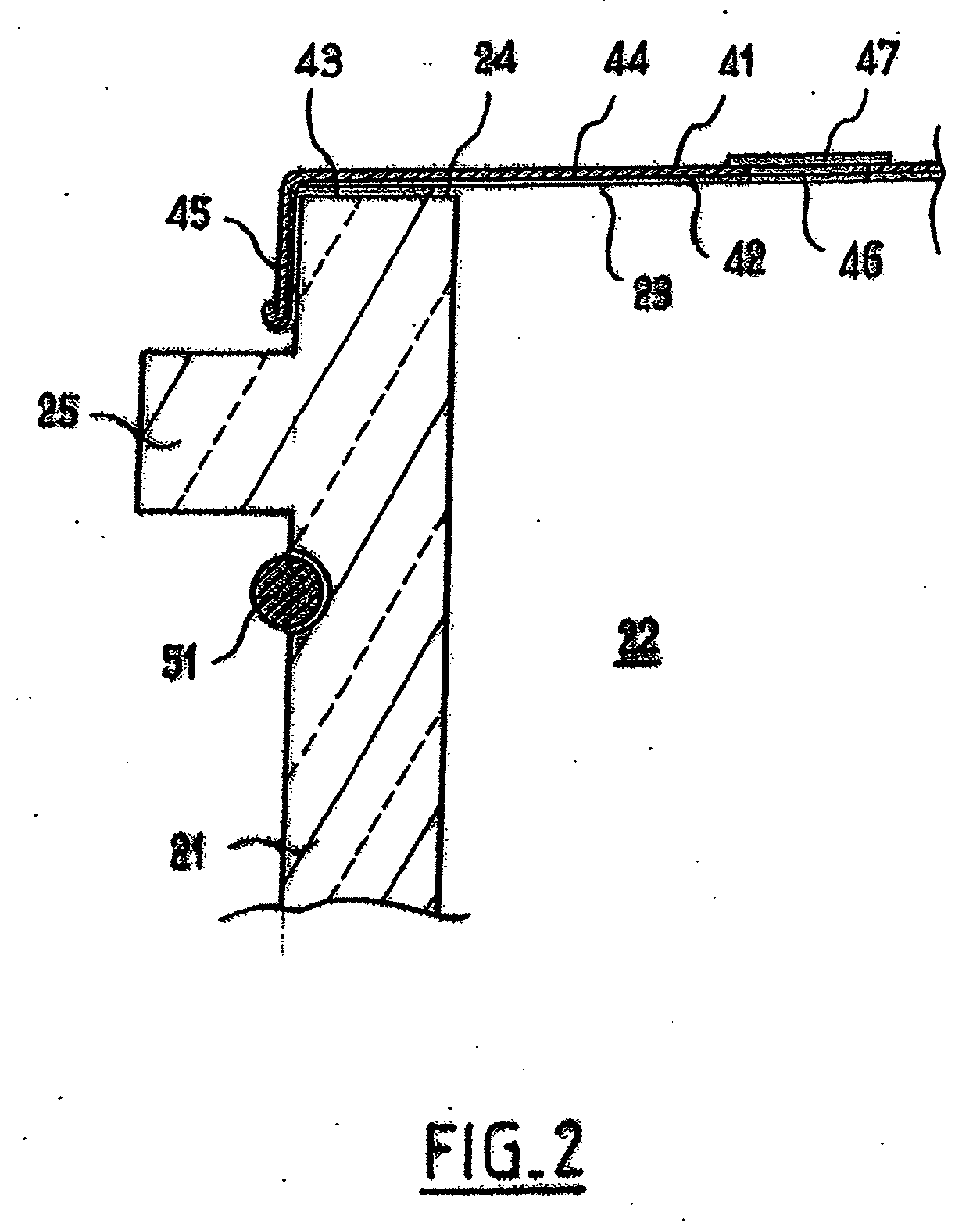

[0051]In FIGS. 1 and 2, the illustrated container 1 comprises a receptacle 2, a lid 3, a capsule 4, and means 5 for connecting the lid to the receptacle.

[0052]The receptacle 2 is a glass jar comprising a wall having a generally cylindrical shape defining an internal cavity 22 designed to accommodate contents, such as a food product for instance.

[0053]The receptacle 2 also comprises an opening 23 limited by an edge 24 of the wall 21 and a ring 25 protruding from the wall 21 in a radial direction with respect thereto, near the opening 23.

[0054]The lid 3 is formed of glass or any other transparent material. The lid 3 is hinged on the receptacle 2 via connecting means 5. In FIG. 1, the lid 23 is illustrated in the open position. The lid 3 can be transferred by rotation into a closed position in which it closes the opening 23.

[0055]As usual, the connecting means 5 comprise frames made of metal wires. The connecting means 5 comprise a first wire frame 51 fastened to the receptacle 2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com