Carrier-free adhesive film

a carrier-free, adhesive film technology, applied in the direction of film/foil adhesives without carriers, film/foil adhesives, paper/cardboard containers, etc., can solve the problems of time-consuming, messy, difficult to achieve, installation failure, etc., and achieve low or substantially no voc emissions, easy unrolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

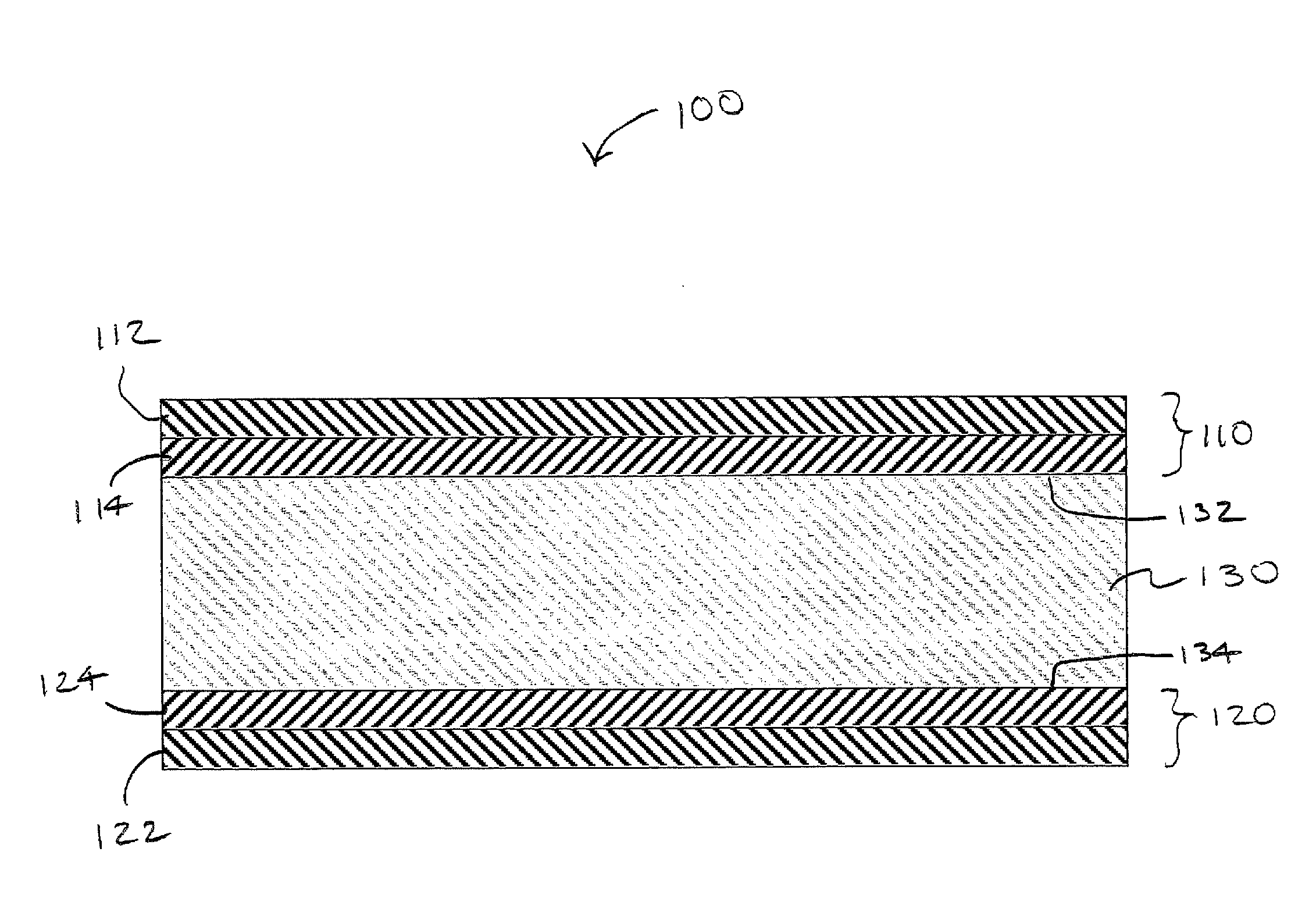

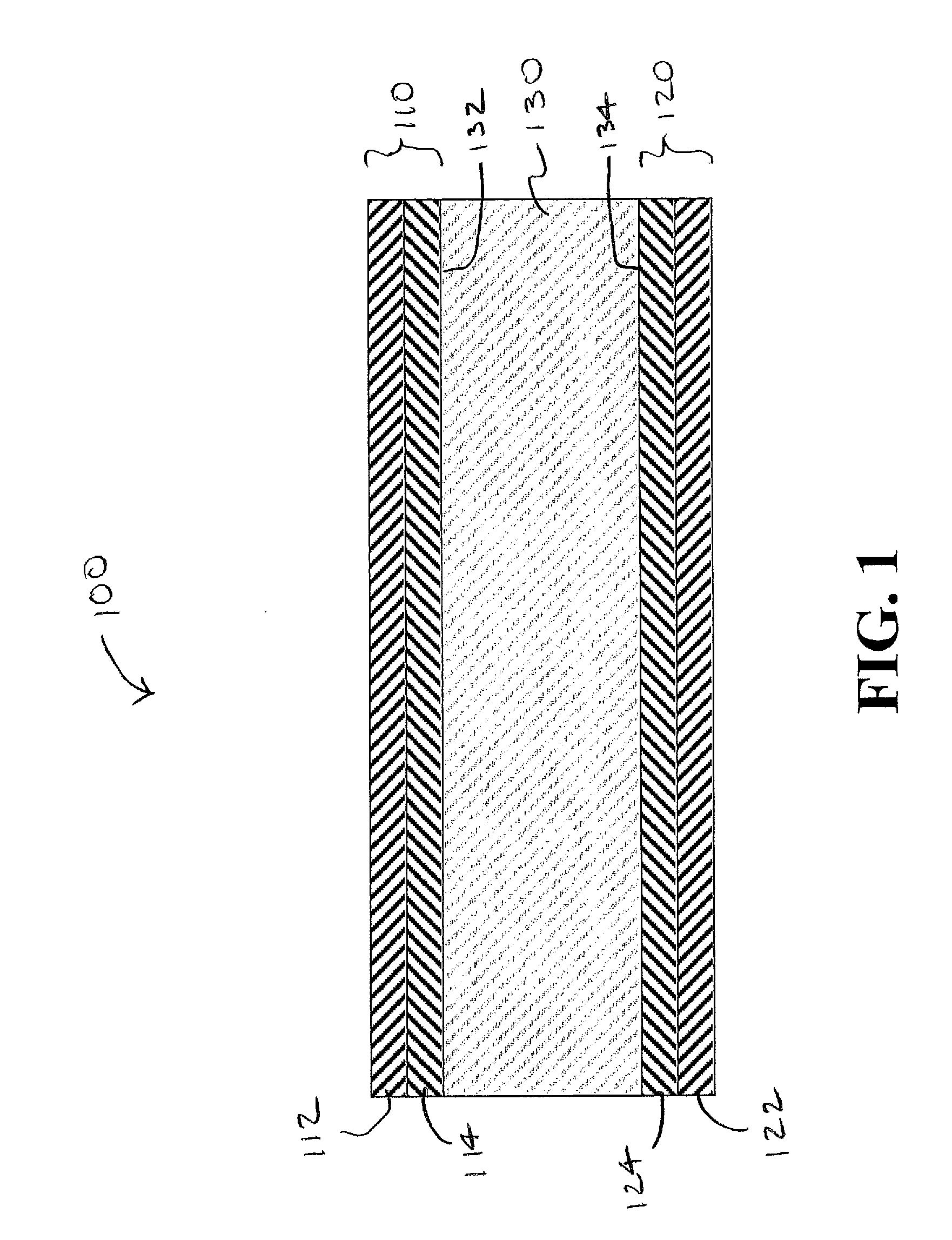

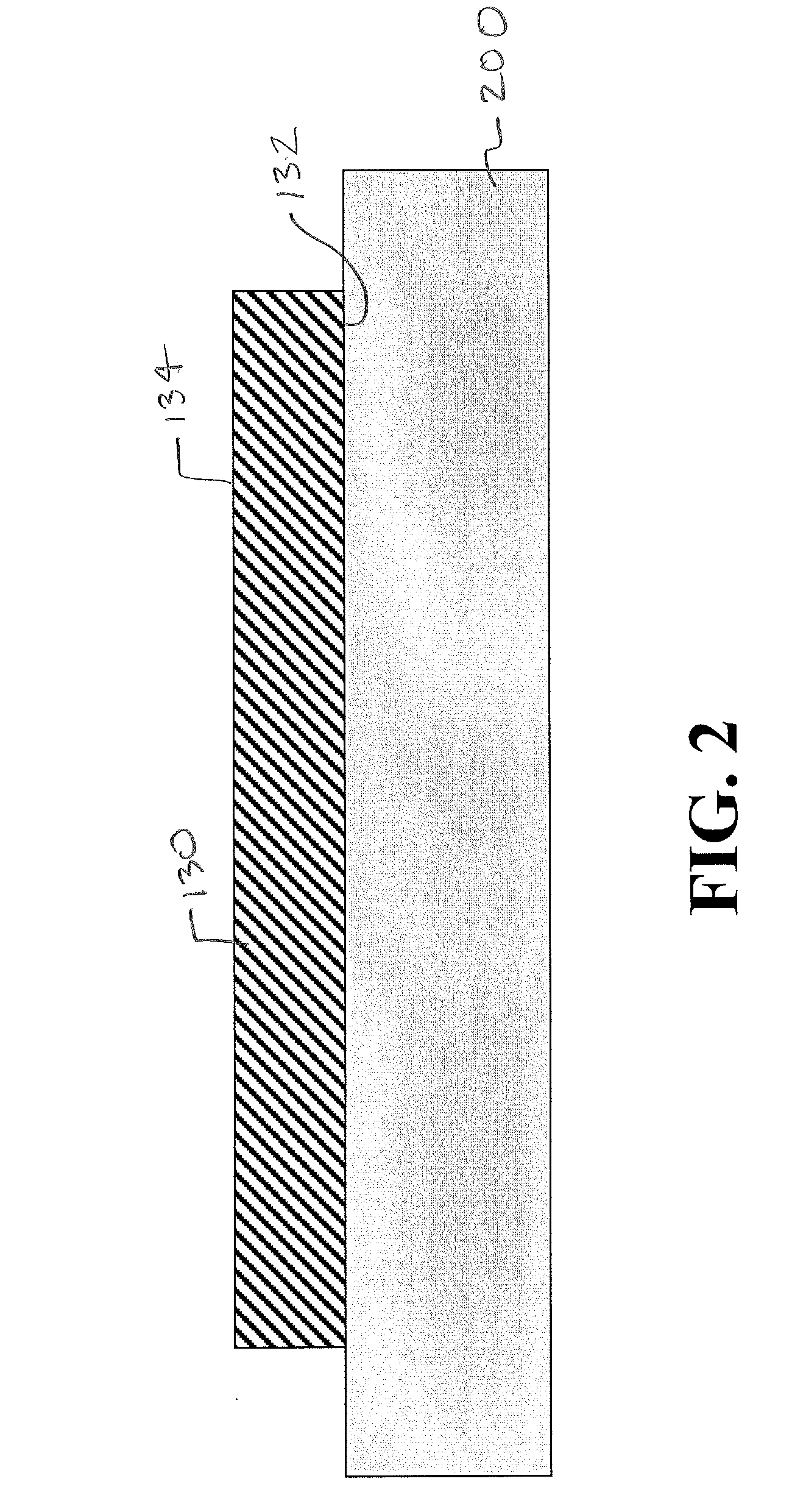

Image

Examples

example 1

Carrier Free Adhesive Film Composition

[0071]

IngredientAmount wt %Process1Drying Oil such as Linseed oil, Tung 4 to 10Blend ingredients that make up theOil, Sunflower Oil, Blown and Heated-aliphatic C-5 hydrocarbon resonbodied Oil, Cashew Shell Oil, Castorwith ingredient 1 (the drying oil)Oil, Coconut Oil, Cotton Seed Oil,resulting in a mixture with a ratio ofDicyclopentadiene Copolymers, Fattybetween 30:60 and 60:40.Acids, Fish Oil, Oiticica Oil, RapeseedOil, Safflower Oil, Sesame Oil, SoybeanOil, Sythentic Oils, Tall Oil,Vinyltoluene Copolymers, Walnut Oil,Naptheneic Oil, Parrafinic Oil.2Aliphatic C-5 Hydrocarbon Resin with a 4 to 10softening point of between 75° and 115° C.,produced from Acyclic Aliphaticmonomers such as Cis 1,3 Pentadiene,Trans 1,3 Pentadiene, 2-Methyl 2Butene3Alkylated Aromatic C-9 Resin with a10 to 20Ingredient 3 is dissolved in thesoftening point of between 100° andabove mixture (ingredients 1 and 2)140° C., produced from C8 to C-10at temperatures of between 2...

example 2

Carrier Free Adhesive Film Composition

[0072]

IngredientAmount wt %Process1Process Oils such as; Naptheneic Oil, 4 to 15Ingredient 2 is dissolved in theParrafinic Oil.above mixture (ingredients 1) at2Tackyfying Resins such as; Alkylated 9 to 20temperatures of between 240° andAromatic C-9 Resin with a softening point of300° F. to form a homogenousbetween 100° and 140° C., produced from C8solution.to C-10 monomers such as Styrene, VinylToluene, Indene, Methyl Indene, Alpha MethylStyrene.Aliphatic C-5 Hydrocarbon Resin with asoftening point of between 75° and 115° C.,produced from Acyclic Aliphatic monomerssuch as Cis 1,3 Pentadiene, Trans 1,3Pentadiene, 2-Methyl 2 ButeneDerivatives of natural tackifiers such as GumRosin, Tall Oil Rosin, Wood Rosin. Examplesof these are Rosin Esters with softening pointbetween 25° C. and 130° C.3Surfactants, such as 1 to 40 mole ethoxylates0.50 to 2.00Ingredients 1 through 5 must beof nonylphenols.premixed and then heated andmaintained at temperature bet...

example 3

Carrier Free Adhesive Film Composition

[0073]

IngredientAmount wt %Process1Process Oils such as; Naptheneic Oil, 4 to 15Parrafinic Oil.2Tackyfying Resins such as; Alkylated10 to 20Ingredient 2 is dissolved in theAromatic C-9 Resin with a softeningabove mixture (ingredients 1) atpoint of between 100° and 140° C.,temperatures of between 240° andproduced from C8 to C-10 monomers300° F. to form a homogenoussuch as Styrene, Vinyl Toluene, Indene,solution.Methyl Indene, Alpha Methyl Styrene.Aliphatic C-5 Hydrocarbon Resin with asoftening point of between 75° and 115° C.,produced from Acyclic Aliphaticmonomers such as Cis 1,3 Pentadiene,Trans 1,3 Pentadiene, 2-Methyl 2Butene3Surfactants, such as 1 to 10 mole0.50 to 1.50Ingredients 1 through 5 must beethoxylates of nonylphenols.premixed and then heated and4Non-Silicon Anti-foaming agents0.05 to 0.10maintained at temperature between240° and 260° F.5Latex Polymer such as Acrylic, Styrene30 to 60Pre-heat and maintain theButadiene, EVA, VAE.tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com