Liquid crystal display and manufacturing method thereof

a technology of liquid crystal display and manufacturing method, which is applied in the field of liquid crystal display, can solve the problems of increasing affecting the performance of limited exposure, so as to improve the response speed against voltage, increase the luminance of the black display, and improve the effect of contras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

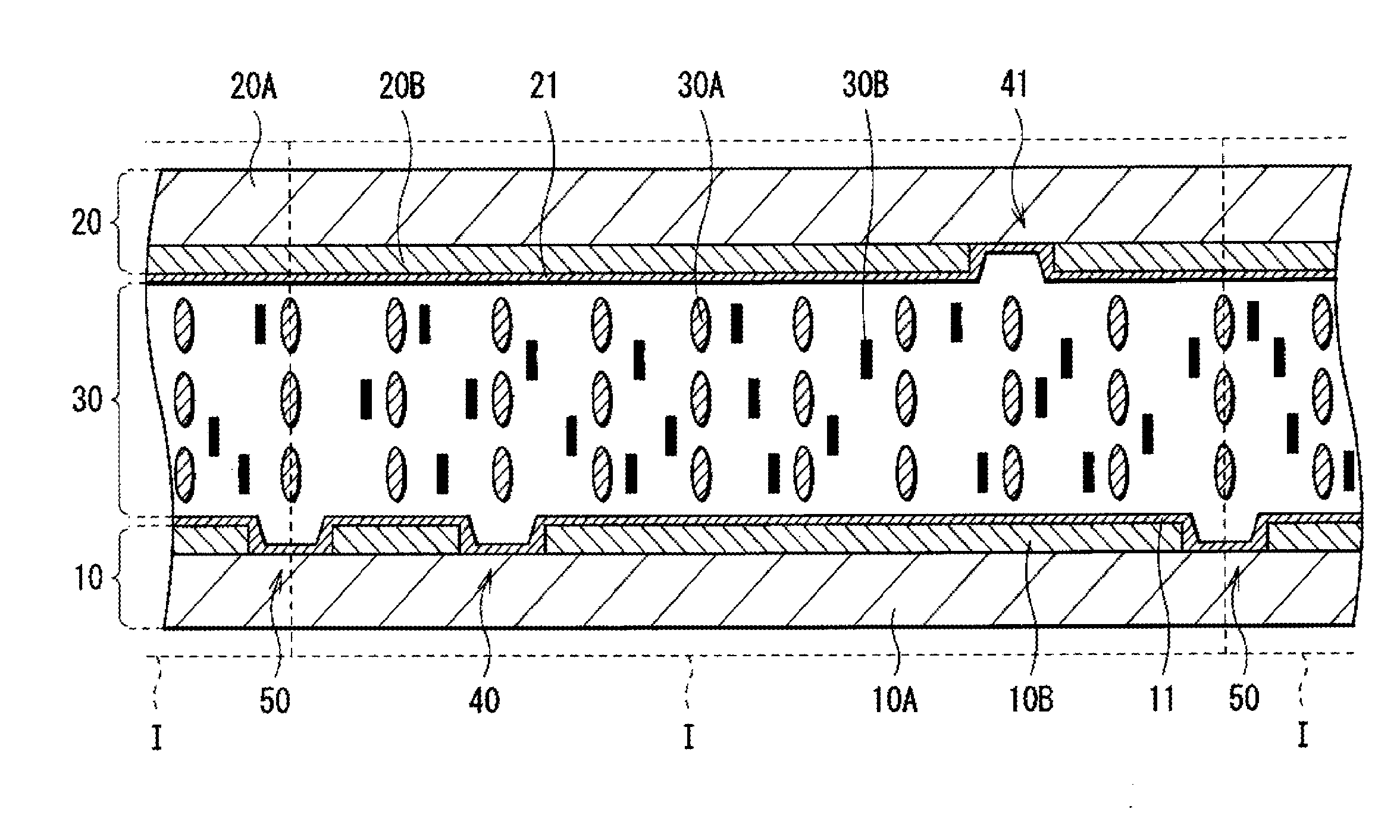

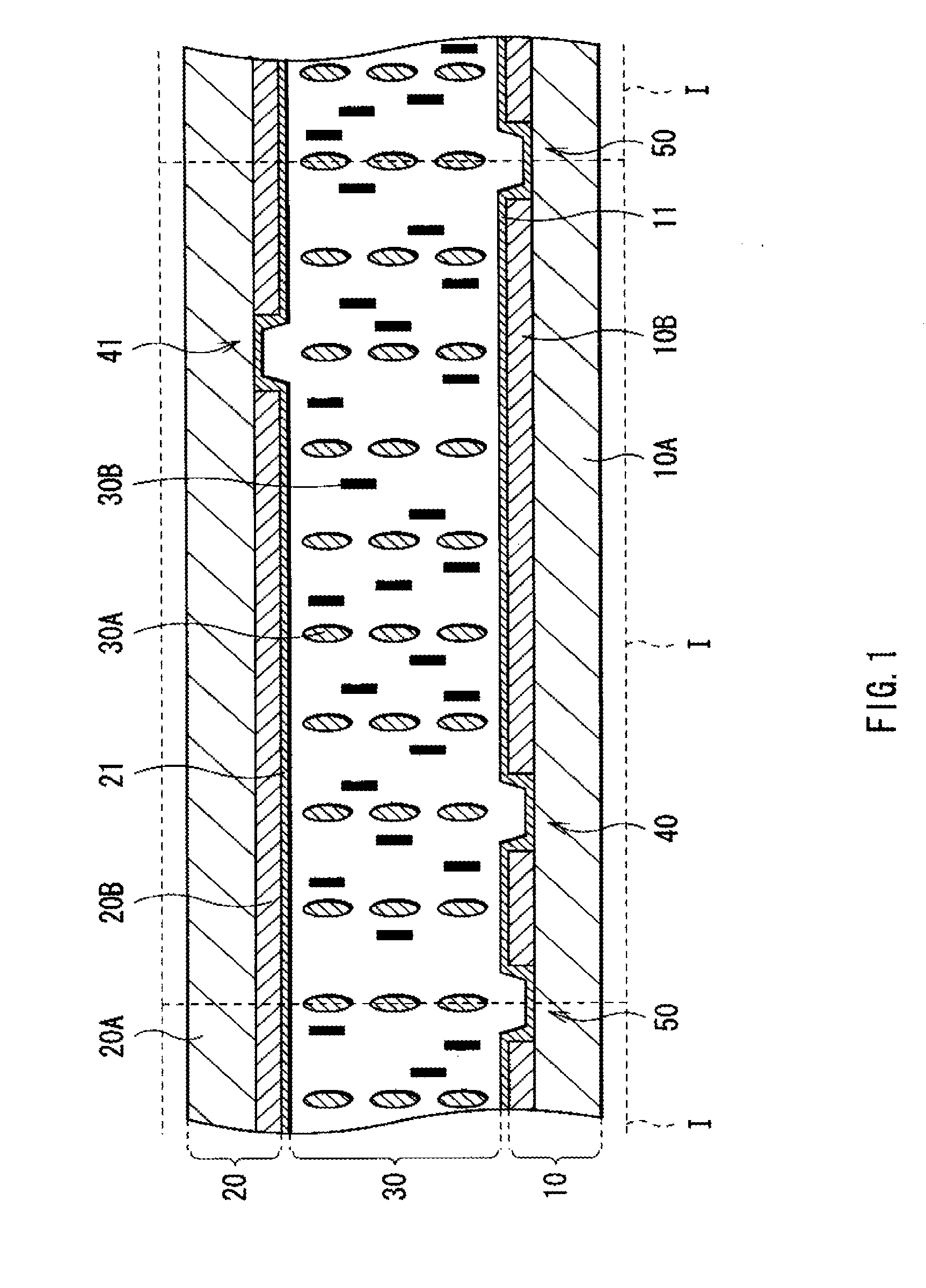

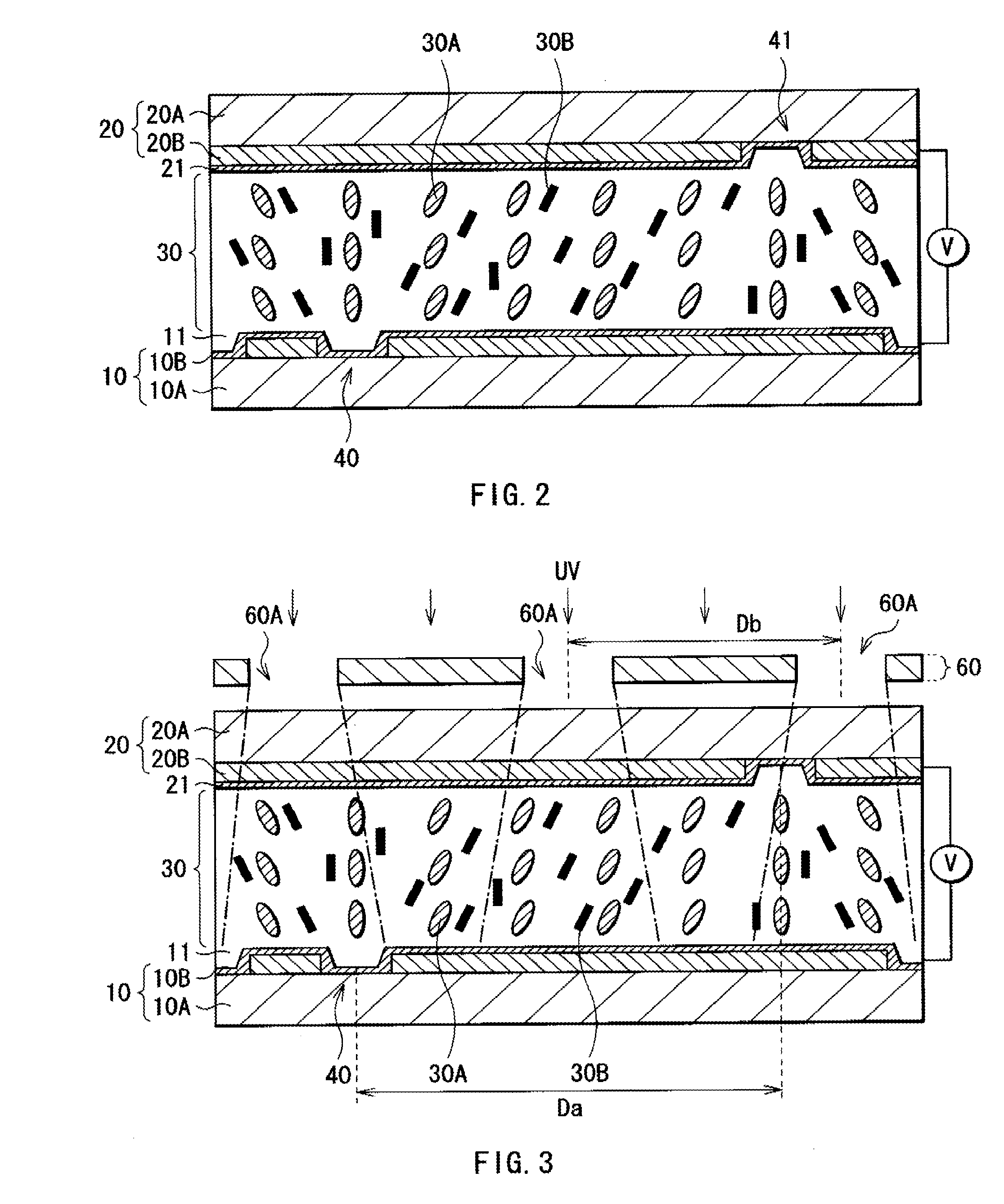

[0033]FIGS. 1 to 4 are cross-sectional views schematically illustrating the manufacturing steps of a liquid crystal panel according to a preferred embodiment of the present invention. The method of manufacturing a liquid crystal display includes the step of forming electrodes having predetermined slit parts on surfaces of a pair of boards, respectively, and then sealing a liquid crystal layer between the boards; and the step of exposing the liquid crystal layer through a predetermined light shielding film, under an applied voltage. This method is for manufacturing a liquid crystal panel where a plurality of pixels are formed between the boards, as shown in FIG. 1. For sake of simplicity, FIGS. 2 and 3 show only a region I (a pixel) in FIG. 1. In FIGS. 1 to 4, specific configurations of each board are omitted.

[0034]Firstly, as shown in FIG. 1, a TFT (thin f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com