Mist Dispersal System for Air Conditioners

a technology of air conditioner and dispersal system, which is applied in air humidification systems, heating types, lighting and heating apparatus, etc., can solve the problems of increased pollution, increased energy consumption, and shorten the life of cooling systems, so as to prevent unwanted scale deposits or corrosion, reduce the electrical energy of device operation, and inhibit the corrosion of condenser parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

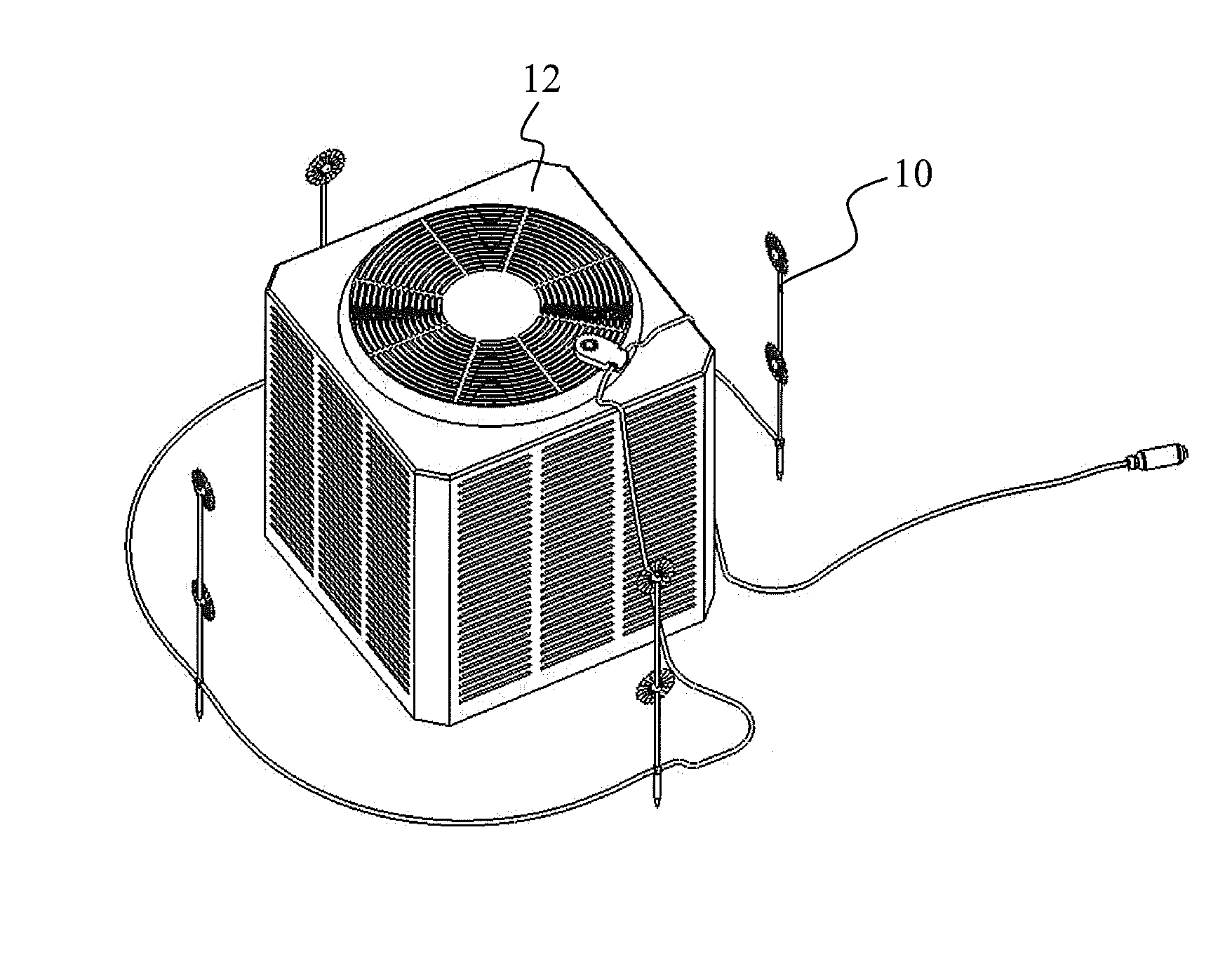

[0034]FIG. 1 shows an embodiment of the present invention improving on prior art systems that apply water or mist to a condenser by utilizing a mist dispersal system 10 for dispersing a water or vapor mist over a condenser unit 12. As described herein, dispersing water or vapor mist onto the condenser of an air cooling unit, improves the efficiency of the air cooling function in air conditioners. The present invention provides a novel apparatus and method for increasing the efficiency of the air conditioner.

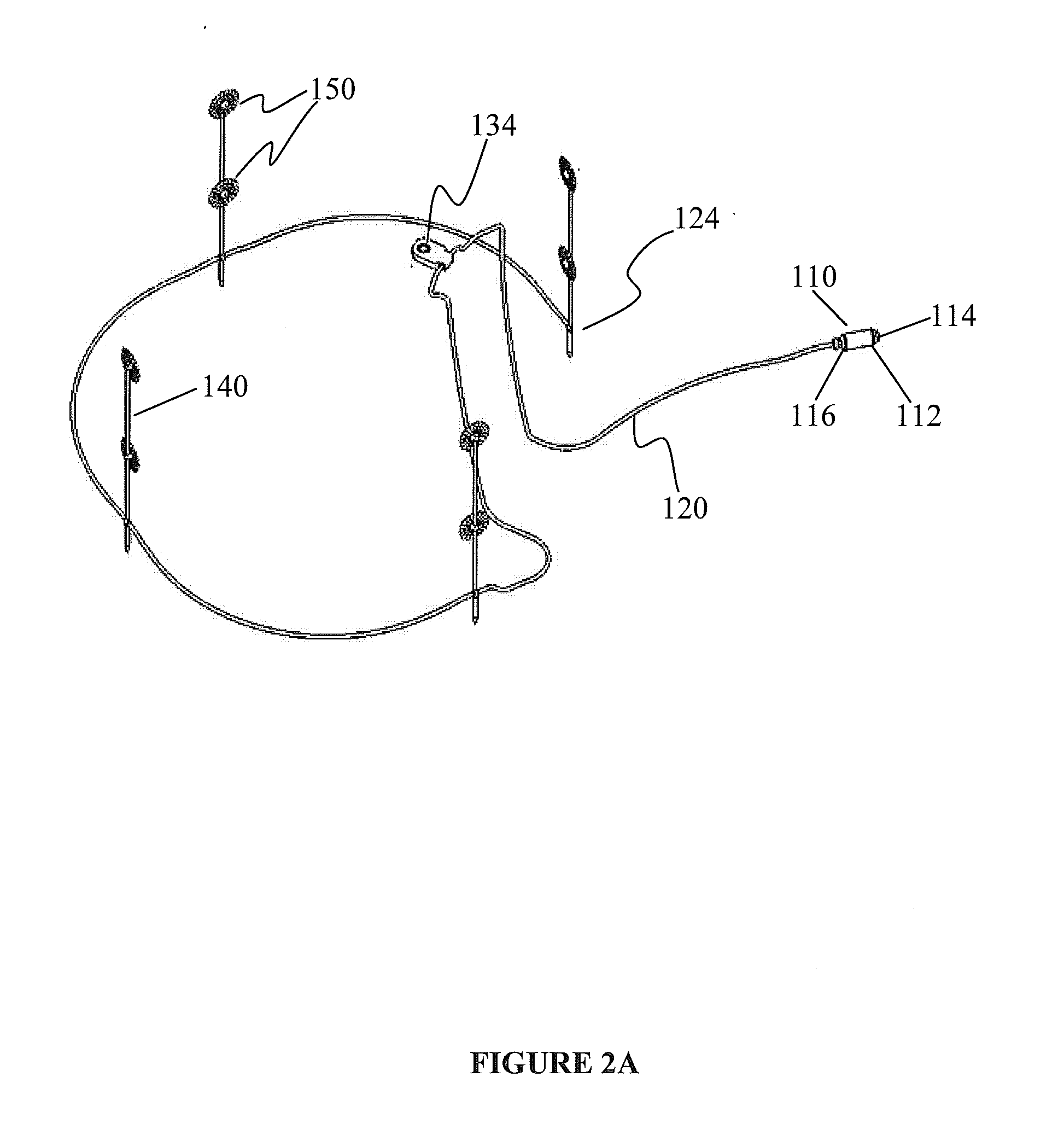

[0035]FIG. 2A shows the mist dispersal system 10 of the present invention which includes a number of components, including the system's main filter 110. In the preferred embodiment the filter 110 is an in-line particulate filter such as a polyphosphate crystal filter 110, although other types of filters may be used. The system's filter 110, which can also serve as a coupling attachment, is shown as containing a garden hose fitting 112. This is the point of connection to a fluid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com