Electromagnetic wave reflecting member

a technology of electromagnetic waves and reflective members, applied in the field of electromagnetic waves reflecting members, can solve the problems of cholesteric liquid, high cost of selectively reflective members, high cost of chemically synthesized and thus high cost, and achieve the effect of high efficiency and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

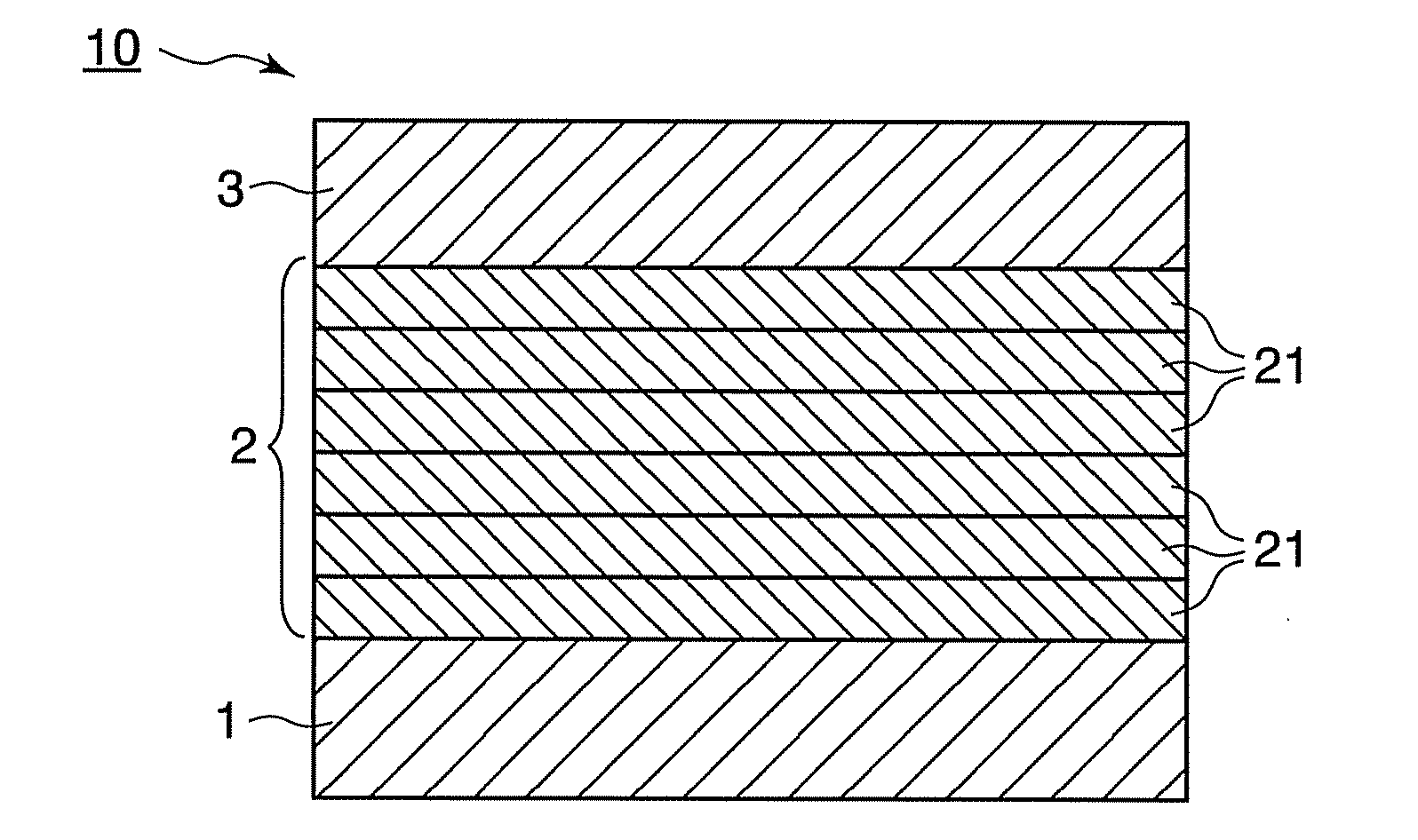

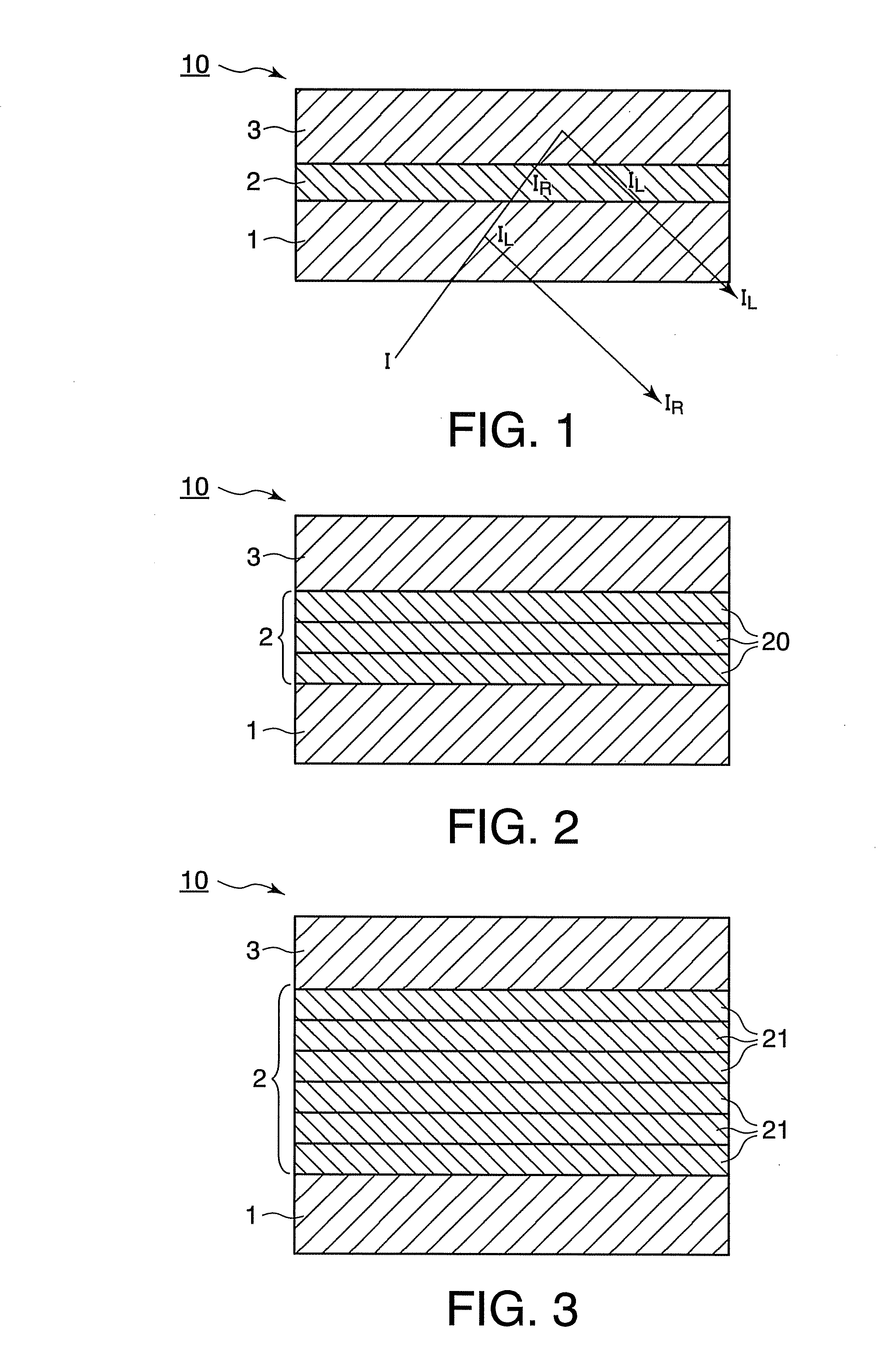

Method used

Image

Examples

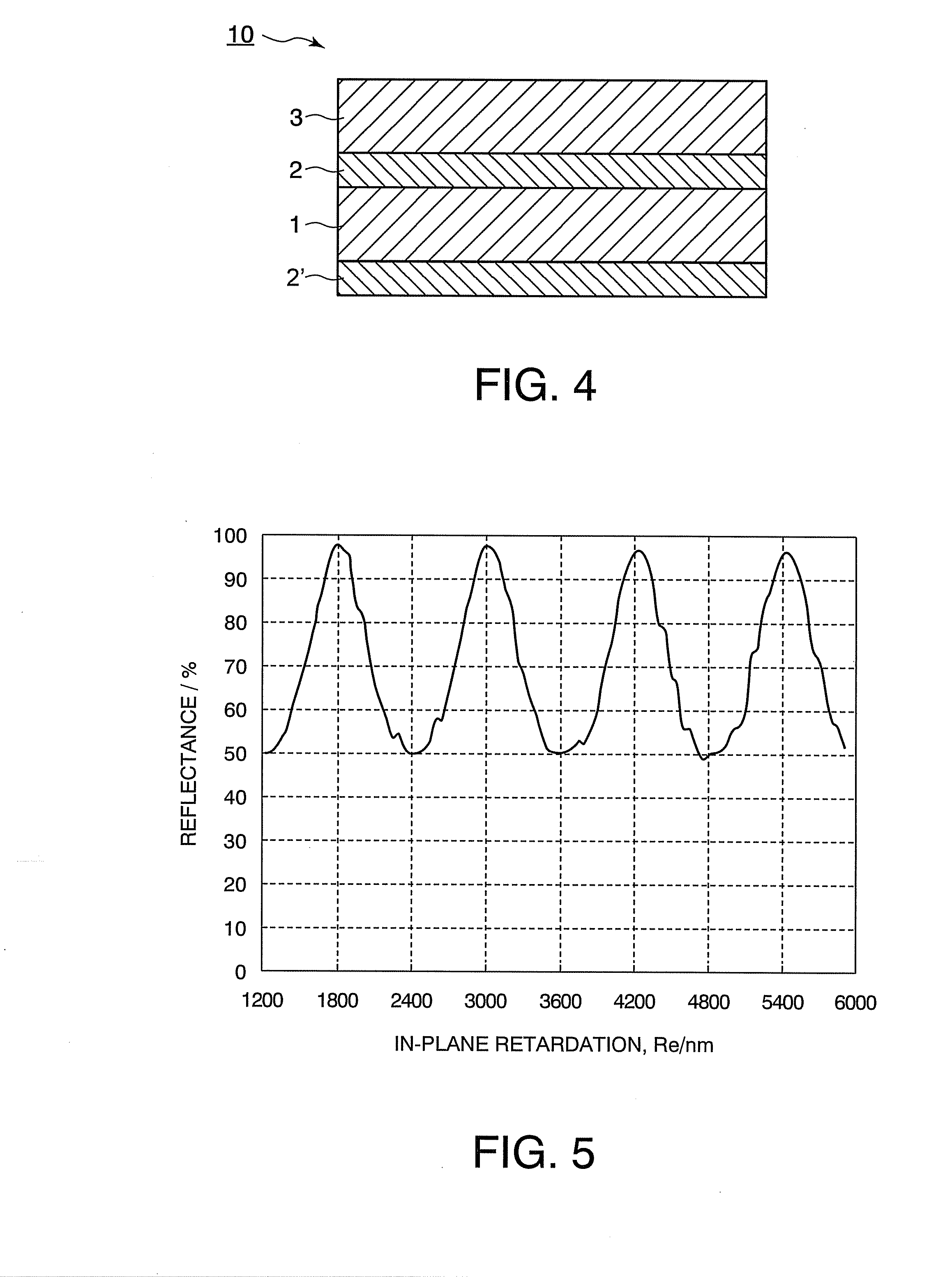

example 1

Provision of Phase Difference Layer

[0068]A biaxially stretched film of polyethylene terephthalate (Lumirror (registered trademark) U35, manufactured by Toray Industries, Inc.) was provided as a phase difference layer. The thickness of the film was 188 μm. The average retardation was measured with KOBRA-WX100 / IR manufactured by Oji Scientific Instruments (measuring angle 0 degree, wavelength 1200 nm) and was found to be about 4083 nm. Accordingly, the biaxially stretched film satisfied formula (1) wherein n=3. Further, the in-plane distribution of the retardation in a transverse direction (TD) of the biaxially stretched film and the in-plane distribution of the retardation in a machine direction (MD) of the biaxially stretched film were as shown in FIGS. 6 and 7.

[0069]A solution of 97.2 parts of liquid crystalline monomer molecules (Paliocolor (registered trademark) LC1057, manufactured by BASF) containing a polymerizable acrylate at both ends thereof and having a spacer between a me...

example 2

[0072]The biaxially stretched film as used in Example 1 was used as a phase difference layer. A selectively reflective layer was formed on one side of the biaxially stretched film in the same manner as in Example 1. Subsequently, the selectively reflective layer was also formed on the other side of the biaxially stretched film in the same manner as described just above to prepare an electromagnetic wave reflecting member. The reflecting properties of the electromagnetic wave reflecting member were measured at a regular reflection angle of 5 degrees with a spectrophotometer and were found to be the same as those shown in FIG. 8 (a solid line).

example 3

[0073]A biaxially stretched film of polyethylene terephthalate (Lumirror (registered trademark) T60, manufactured by Toray Industries, Inc.) was used, instead of the biaxially stretched film used in Example 1, as a phase difference layer. The thickness of the film was 38 μm. The average retardation was measured with KOBRA-WX100 / IR manufactured by Oji Scientific Instruments (measuring angle 0 degree, wavelength 1200 nm) and was found to be about 1944 nm. Accordingly, the biaxially stretched film satisfied formula (1) wherein n=1. Further, the in-plane distribution of the retardation in a transverse direction (TD) of the biaxially stretched film and the in-plane distribution of the retardation in a machine direction (MD) of the biaxially stretched film were as shown in FIGS. 9 and 10.

[0074]An electromagnetic wave reflecting member was prepared by forming a selectively reflective layer on both sides of the biaxially stretched film in the same manner as in Example 2. The reflecting prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com