Method for producing multilayer laminated film

a laminated film and multi-layer technology, applied in the direction of synthetic resin layered products, packaging, polarising elements, etc., can solve the problems of insufficient prevention of bubble production between resin films, wrinkles or stripe-like irregularities can also be produced, etc., to achieve good appearance, prevent wrinkles or stripe-like irregularities, and high in-plane uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Polarizing Plate

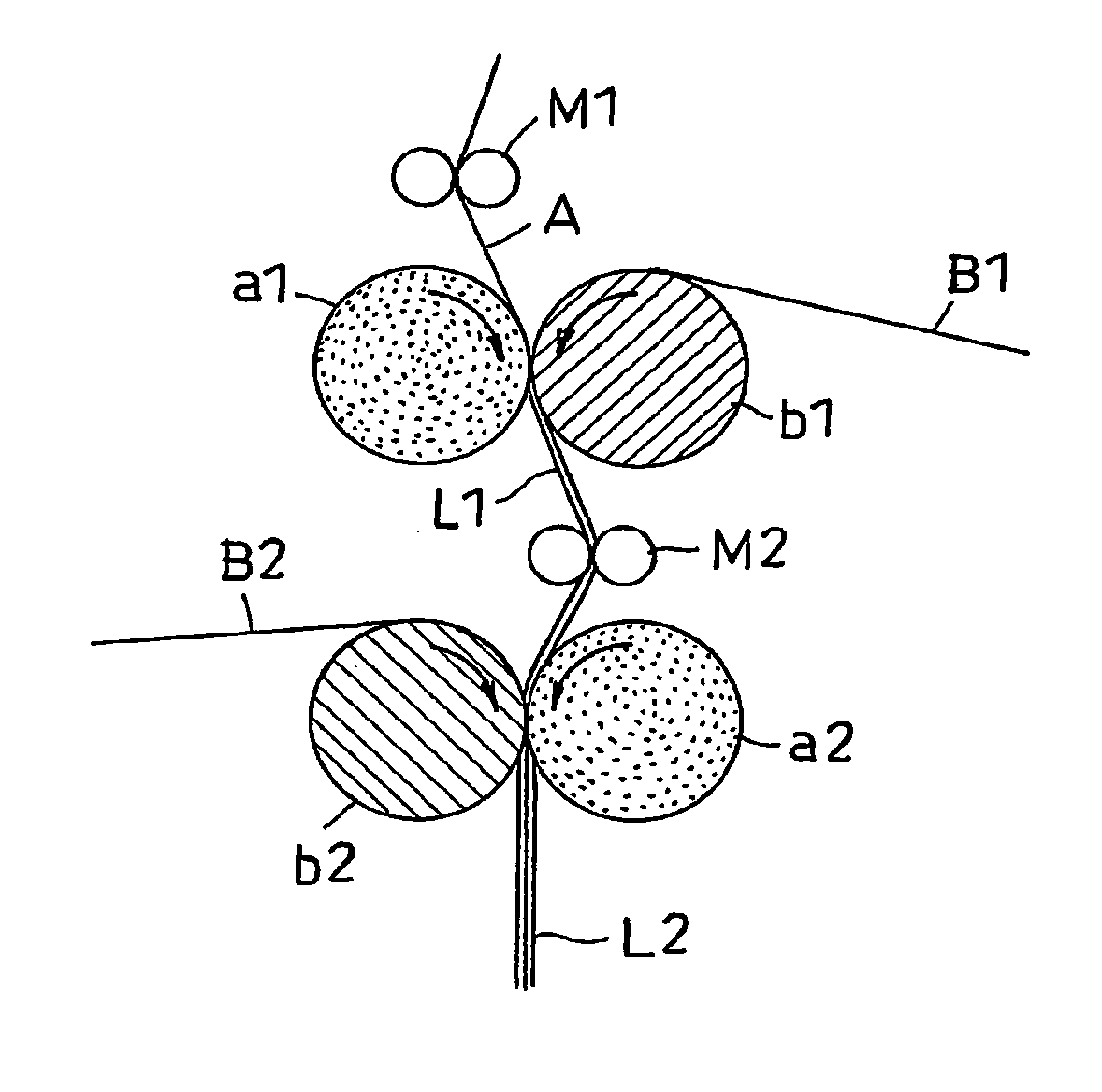

[0164]A polarizing plate was prepared using the method shown in FIG. 1. The polarizing film was used as the resin film A, and the adhesive layer-attached TAC film was used as each of the first and second transparent films B1 and B2. The feeding of the adhesive layer-attached TAC film was performed in such a manner that the TAC film side was placed on the first metal roll b1 side and on the second metal roll b2 side. An iron roll with a diameter of 200 mm was used as each of the first metal roll b1 and the second metal roll b2. A roll with a diameter of 200 mm composed of an iron core and a rubber layer (with a hardness of 90 degrees and a thickness of 3 mm) provided around the iron core was used as each of the first elastic roll a1 and the second elastic roll a2.

[0165]The polarizing film and the adhesive layer-attached TAC film were fed between the first elastic roll and the first metal roll and bonded to each other under pressure so that a laminated f...

examples 2 to 18

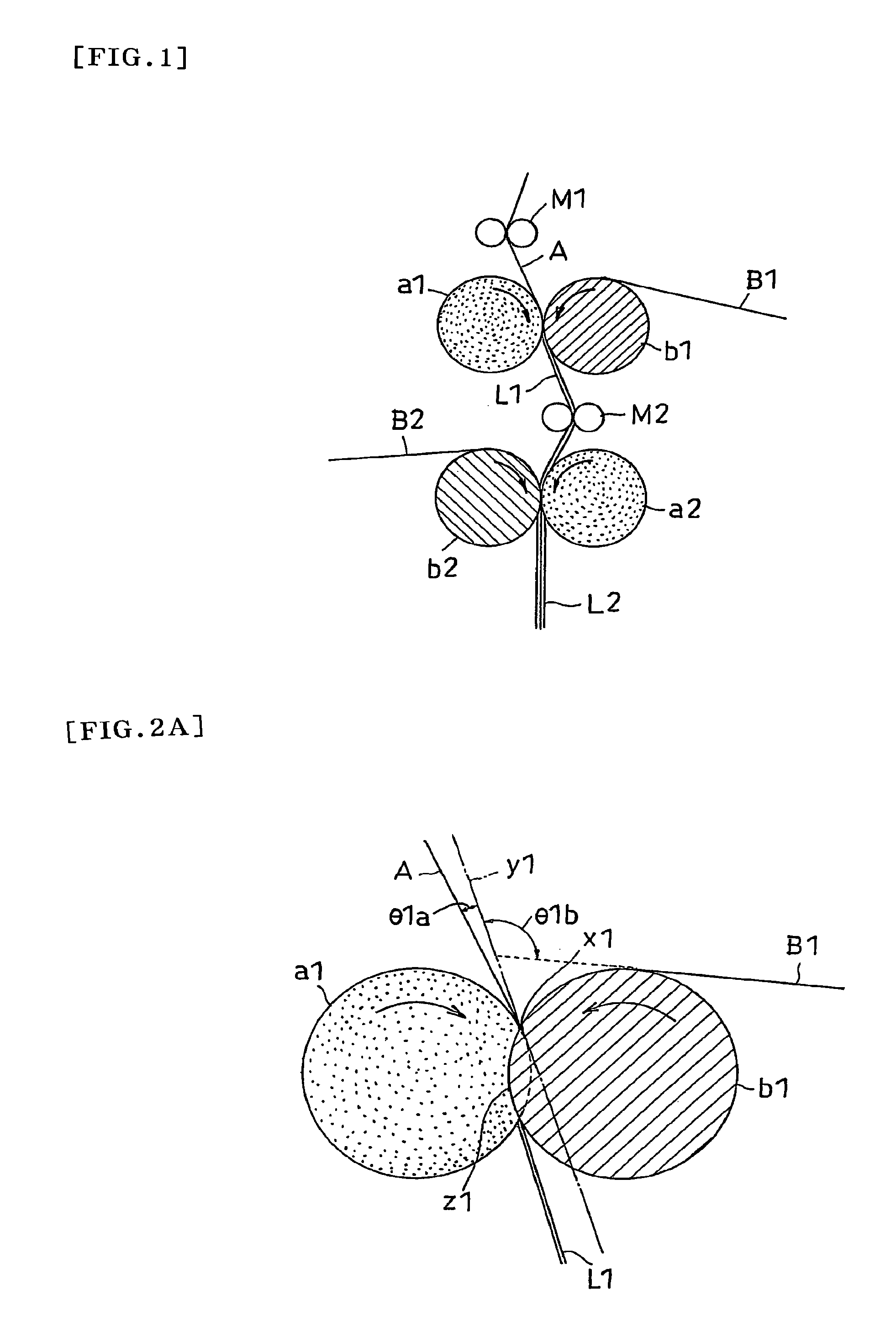

[0168]Polarizing plates were obtained using the process of Example 1, except that the angle (θ1a) or (θ1b) made by the line of feeding of each film with the tangent line (y1), the angle (θ2a) or (θ2b) made by the line of feeding of each film with the tangent line (y2), or the lamination pressure was changed as shown in Table 1.

example 19

[0169]A polarizing plate was obtained using the process of Example 16, except that the rubber layer of each of the first elastic roll and the second elastic roll was replaced by a rubber layer with a hardness of 65 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com