Iron-nickel-chromium-silicon alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0098]As already stated in the foregoing, Tables 1 to 3 reflect the prior art.

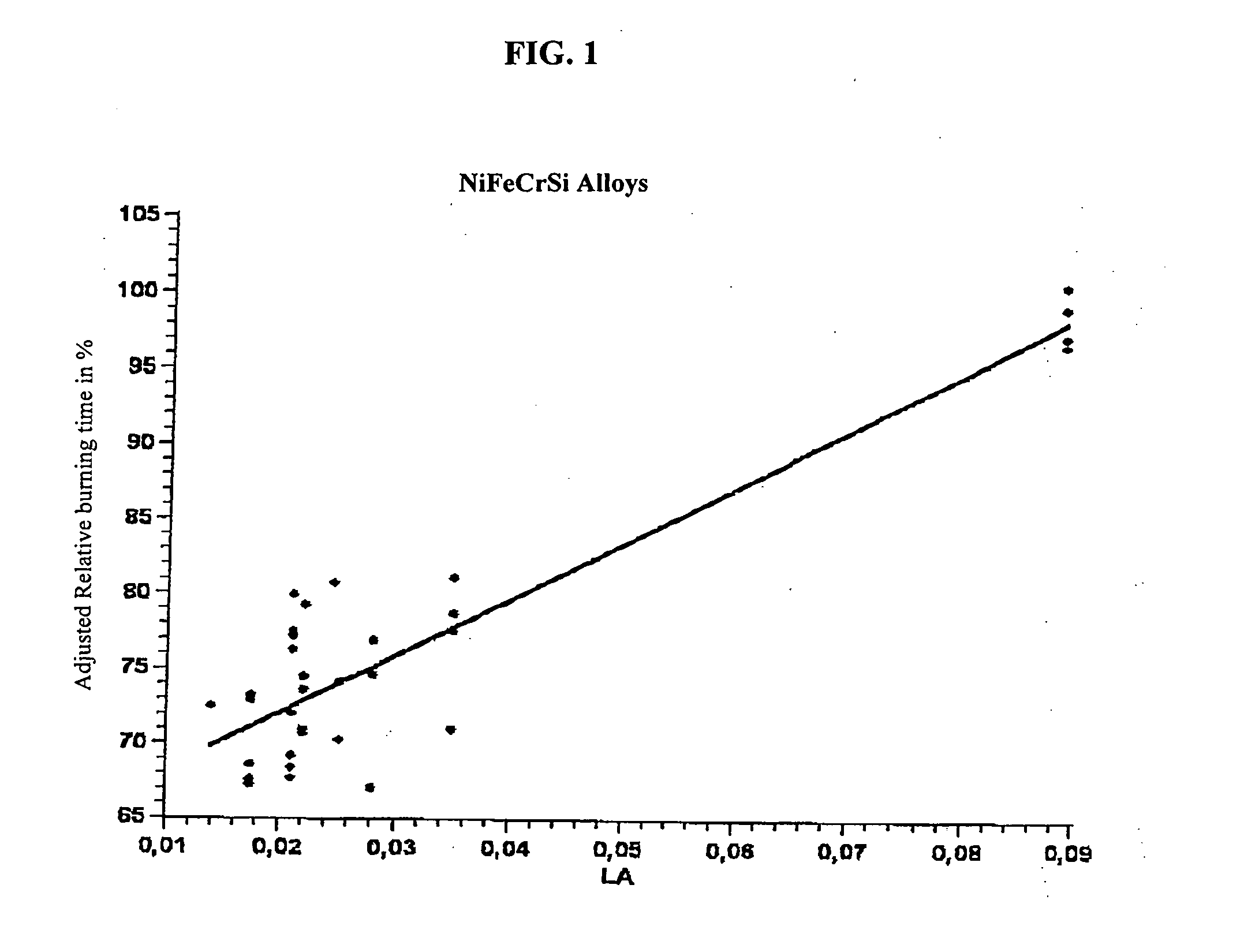

[0099]For the alloys smelted on an industrial scale in the following examples, a commercially produced and soft annealed specimen having a 1.29 mm diameter was taken. A smaller quantity of the wire, on a laboratory scale of up to 0.4 mm, was taken for the service life test.

[0100]For heating elements, especially heat conductors in the form of wire, accelerated service life tests for comparing materials to one another are possible and usual for example with the following conditions:

[0101]The heat conductor service life test is performed on wires that have a diameter of 0.40 mm. The wire is clamped between 2 power supplies spaced 150 mm apart and is heated to 1150° C. by applying a voltage. Each heating interval to 1150° C. is performed for 2 minutes and then the power supply is interrupted for 15 seconds. The wire fails at the end of its service life in that the rest of the cross-section melts through. The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com