Friction weld vibration quality monitoring system

a vibration quality monitoring and vibration technology, applied in the field of friction welding system and method, can solve the problems of insufficient reliability, high cost, and high cost of systems and equipment for damping, so as to reduce or eliminate the need, and improve the quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

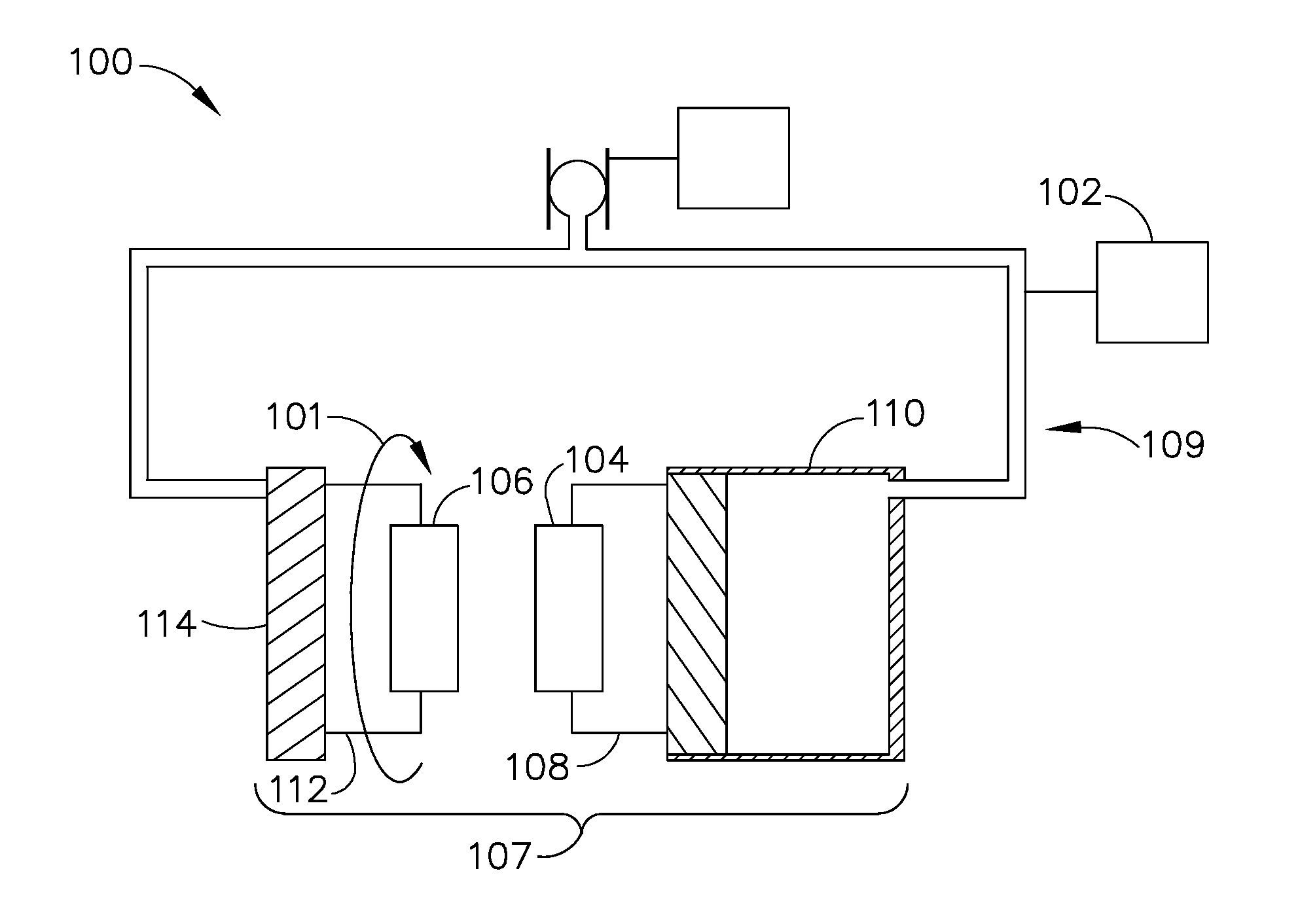

[0017]FIG. 1 shows a friction welding system 100. The friction welding system 100 may include an inertial welding arrangement 107, a force providing mechanism 109, and a sensor 102. Inertial welding arrangement 107 is configured to impart a kinetic friction between at least one surface of a first workpiece 104 and at least one surface of a second workpiece 106. Welding arrangement 107 can include a first securing mechanism 108 arranged and disposed for receiving and securing first workpiece 104. As shown, first workpiece 104 is detachably secured by first securing mechanism 108, which prevents rotation of first workpiece 104. First securing mechanism 108 can be attached to or integral with a hydraulic cylinder 110. Welding arrangement 107 can further include a second securing mechanism 112 arranged and disposed to receive and secure second workpiece 106. As shown, second workpiece 106 can be secured by second securing mechanism 112, while permitting second workpiece 106 to rotate (s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com