Assembly type oil cooler for intensively cooling hydraulic machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

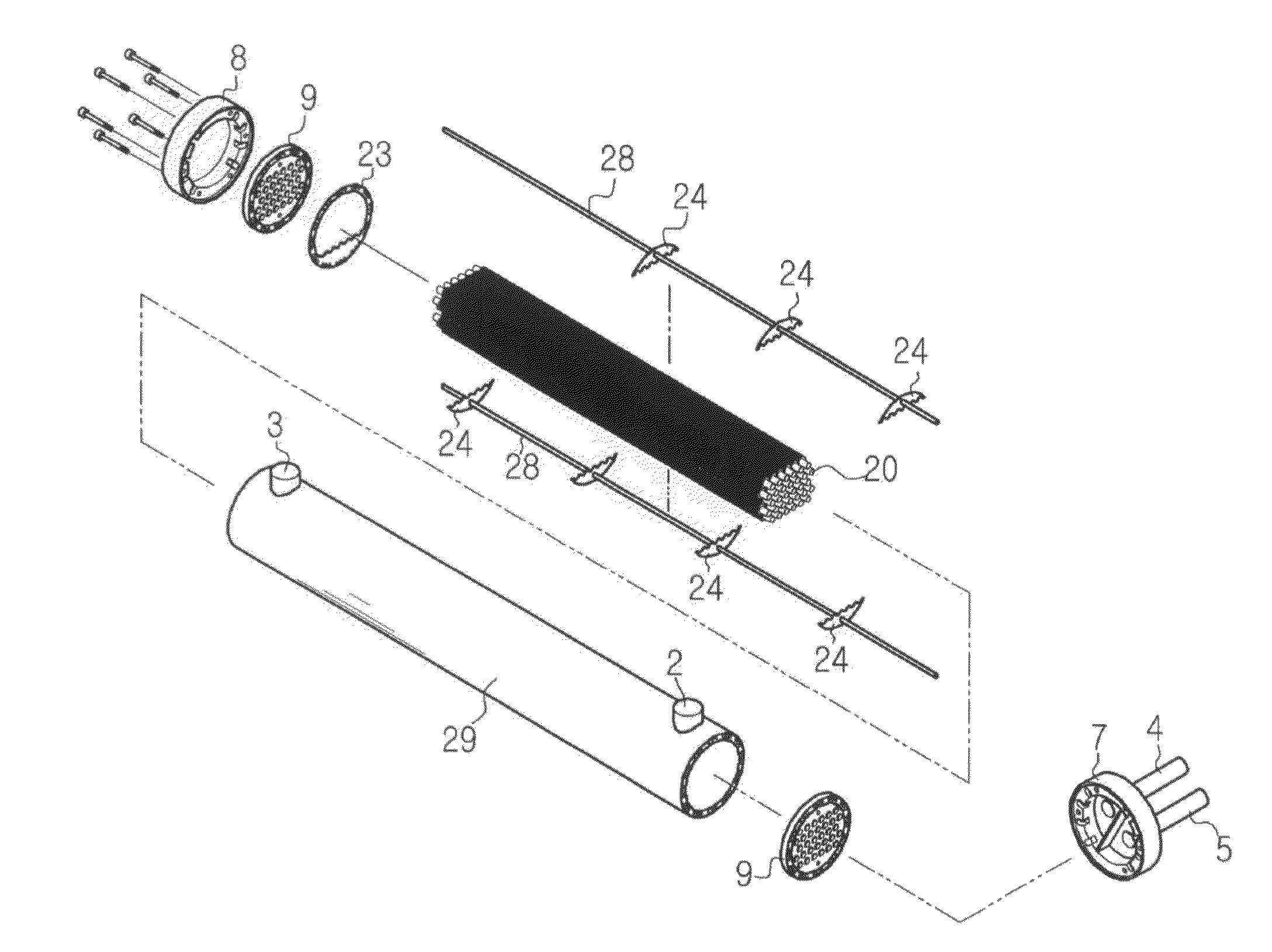

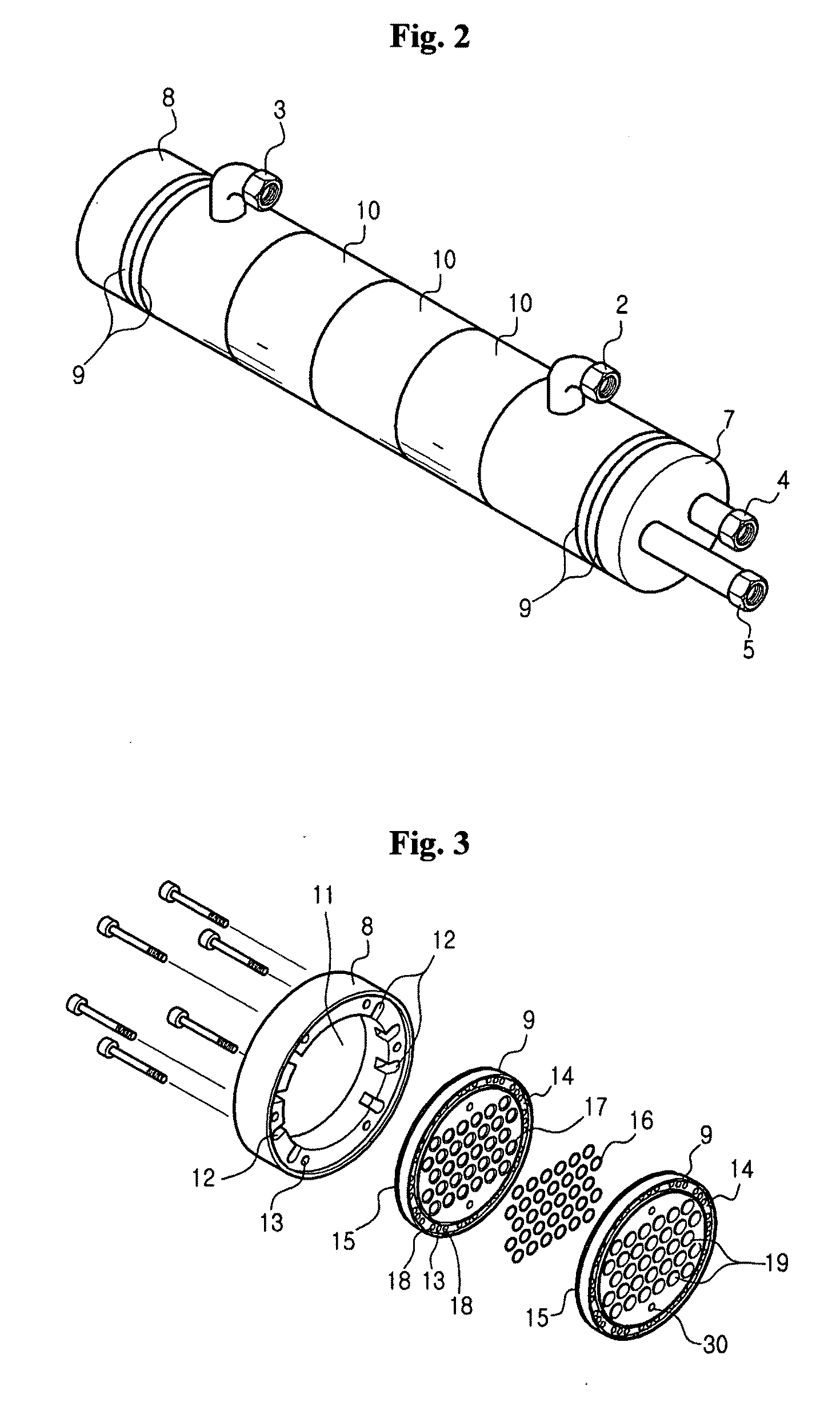

[0020]Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the appended drawings.

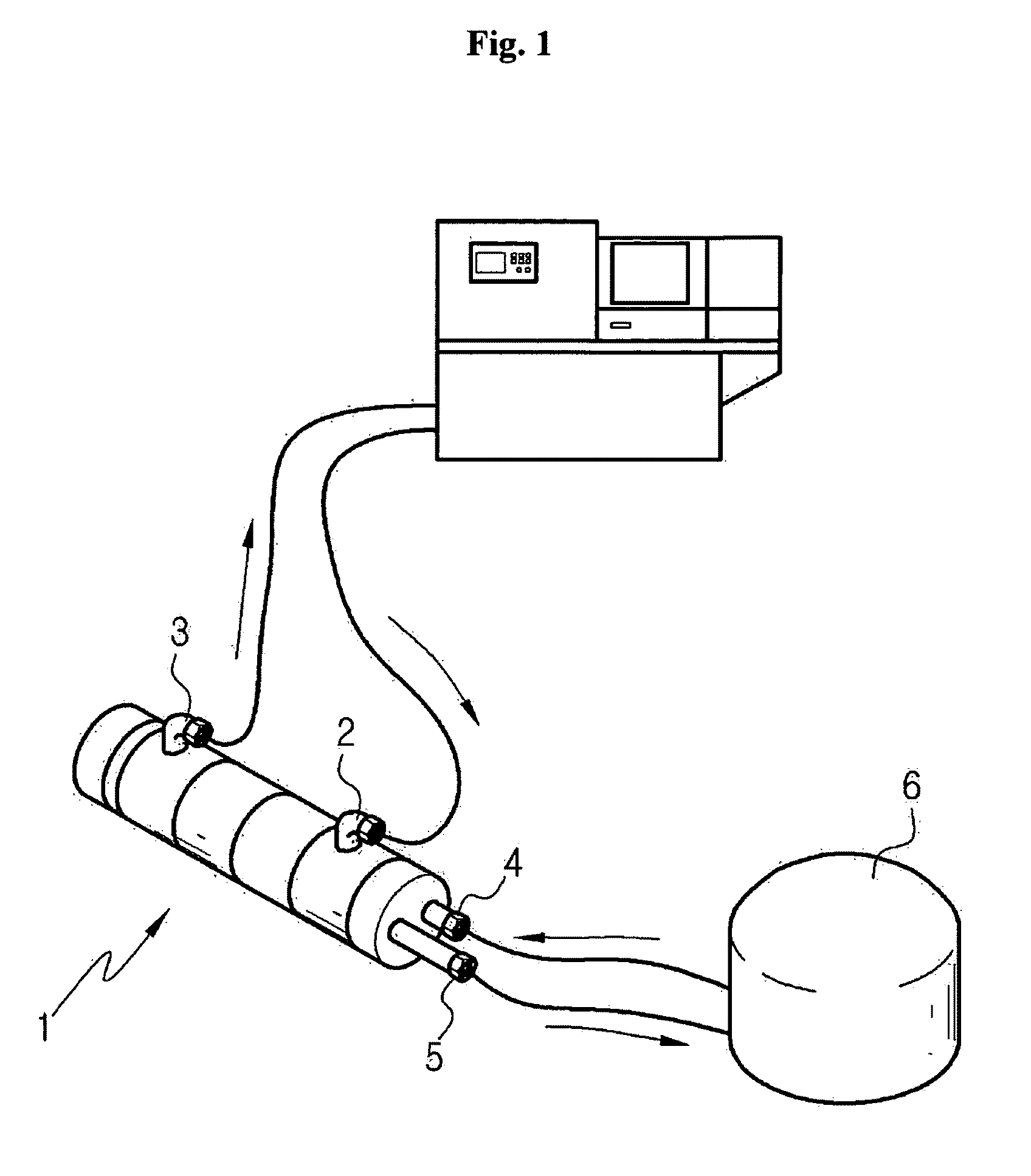

[0021]In the drawings, FIG. 1 is a view showing a use state of the present invention.

[0022]As shown in FIG. 1, a cooling water inlet 4 and a cooling water outlet 5 of a hydraulic-operating oil cooling apparatus 1 is connected to a cooling water tank 6 so that cooling water can circulate through the inside of a heat exchange pipe 20 disposed at the inside of the hydraulic-operating oil cooling apparatus 1, an oil inlet 2 and an oil outlet 3 of the hydraulic-operating oil cooling apparatus 1 are connected to a hydraulic machine so that hot hydraulic-operating oil can flow through the outer side of the heat exchange pipe 20 disposed at the inside of the hydraulic-operating oil cooling apparatus 1.

[0023]In this regard, heat exchange is produced between the hot hydraulic-operating oil, which is circulating from the hydraulic machine to the hydraulic-op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com