Mixtures For Forming Porous Constructs

a technology of porous constructs and mixtures, applied in the field of preparation of mixtures, can solve the problems of difficult mixing, inability to separate the respective constituents of the combination, and inability to meet the requirements of the patient,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Stability of Inventive Mixtures

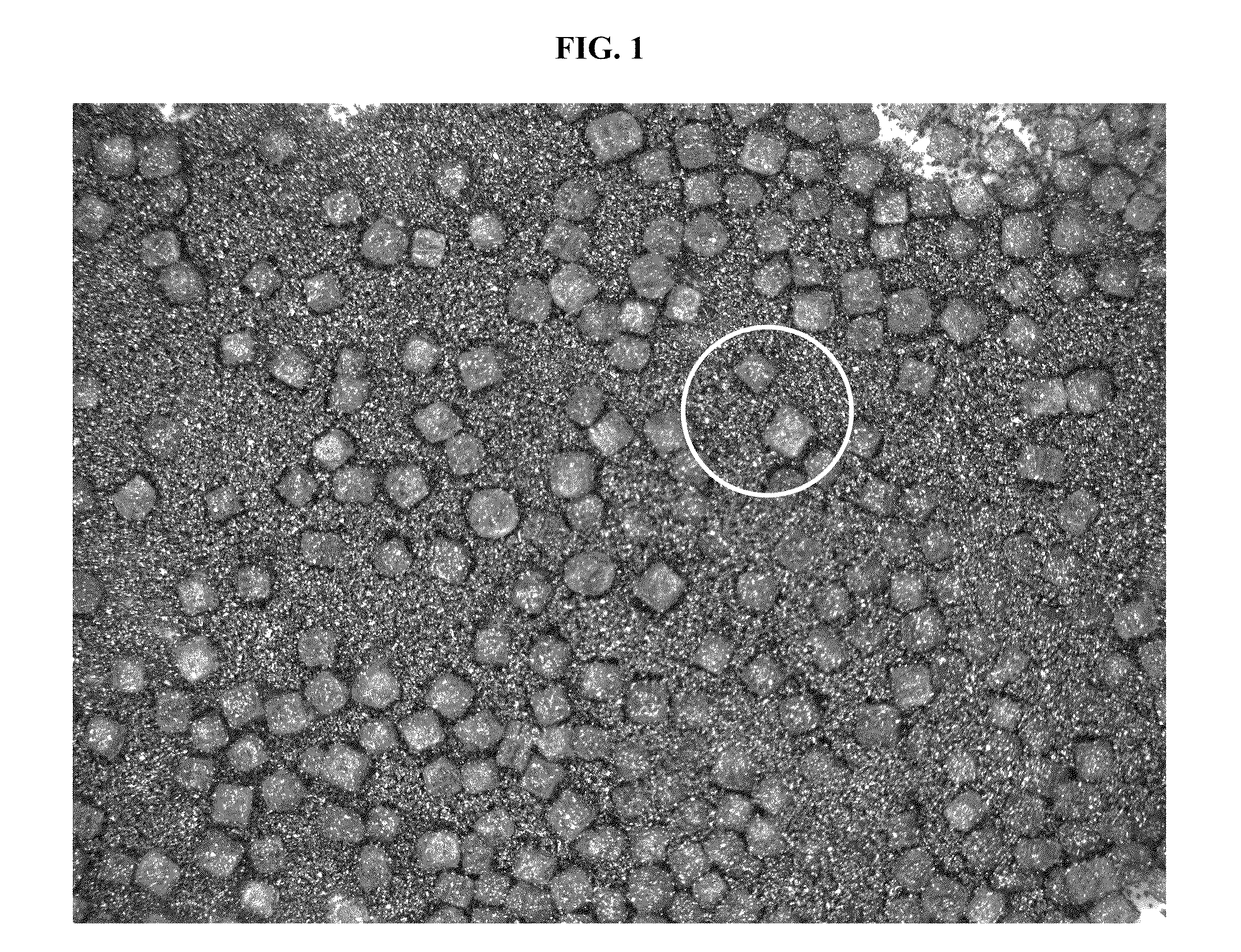

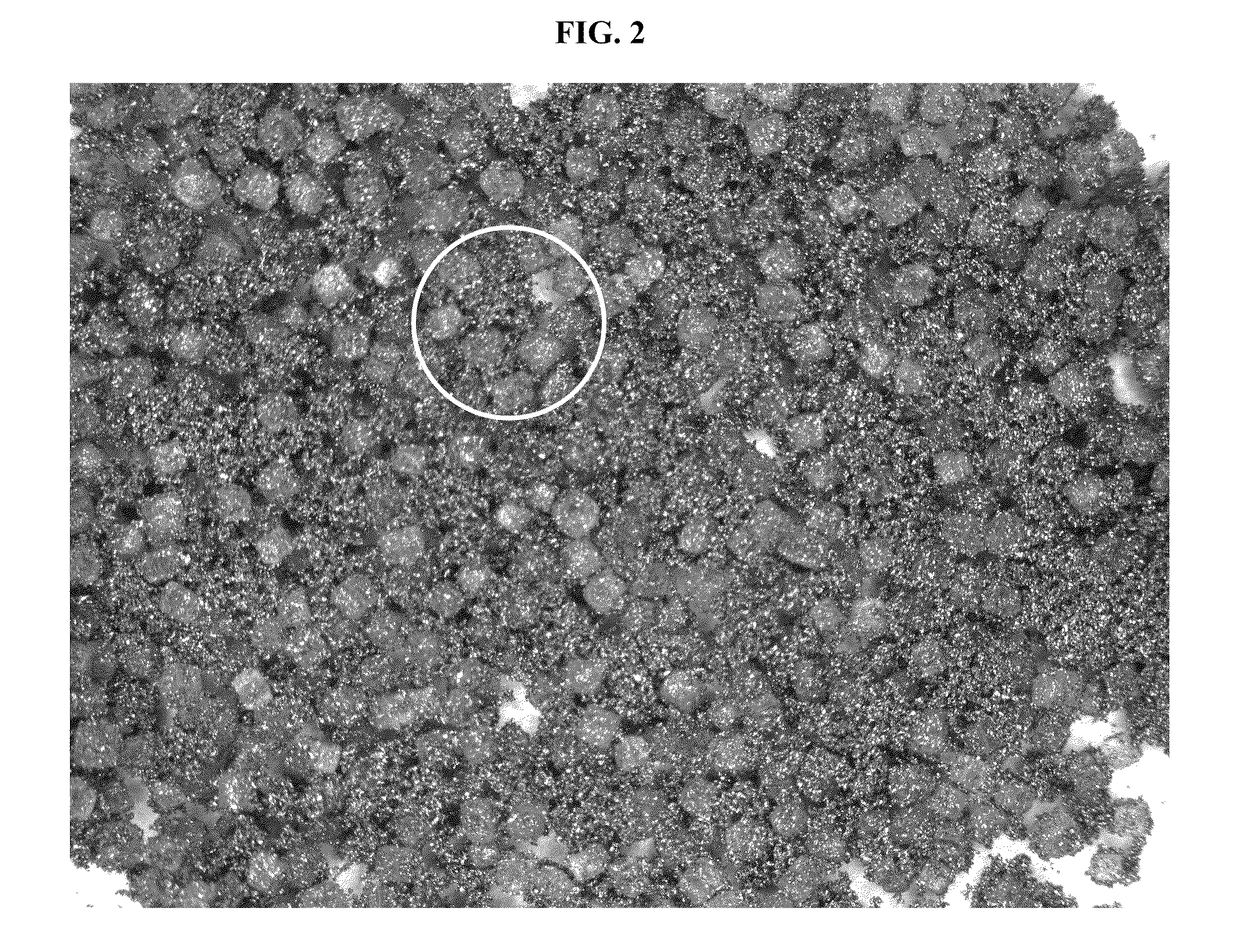

[0031]A first mixture comprising titanium metal powder, NaCl extractable material, and glycerol solution was prepared. A second mixture comprising titanium metal powder, NaCl and reverse osmosis (RO) water was also prepared, and both mixtures were placed under a fume hood in separate open containers. Both mixtures were left undisturbed under the fume hood for a period of four days. As shown in FIG. 1, the mixture that was prepared using RO water did not remain well-mixed following the four-day period; the circled portion of FIG. 1 clearly shows the segregation of NaCl particles from the particles of titanium. In contrast, the mixture that was prepared using glycerol solution remained well-mixed following the same four-day period, with no visible segregation of the salt particles from the metal powder (circled portion of FIG. 2). A third mixture, comprising titanium metal powder, NaCl extractable material, and glycerol solution, was prepared and placed ...

example 2

Porosity of Sintered Bodies

[0033]Three separate mixtures were prepared. The first mixture comprised a combination of titanium powder, NaCl, and 25% by volume glycerol solution as a homogenizing agent. The second mixture included the same ingredients but used a 50% glycerol solution instead of a 25% solution, and the third mixture also included titanium powder and NaCl, but made use of reverse osmosis (RO) water as the homogenizing agent rather than glycerol. Each of the three mixtures were subsequently compacted, exposed to aqueous solvent to remove the NaCl particles, and sintered to form a porous body. The three samples were otherwise alike with respect to titanium powder particle size, salt particle size, green porosity, the total quantity of homogenizing agent combined with the titanium powder and NaCl, compaction pressure, sintering temperature, and sintering time.

[0034]The porosity of each of the three samples was measured by an imaging process using Image-Pro®Plus software (M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com