Abnormality detecting method for automatic ice making machine

a technology abnormal detection method, which is applied in the field of abnormal detection method of automatic ice making machine, can solve the problems of increasing maintenance cost, abnormality cannot be detected, ice blocks may deform or damage the ice making plate, etc., and achieves the effect of delay or shortening the ice making time and quick detection of abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

(Operation of Embodiment)

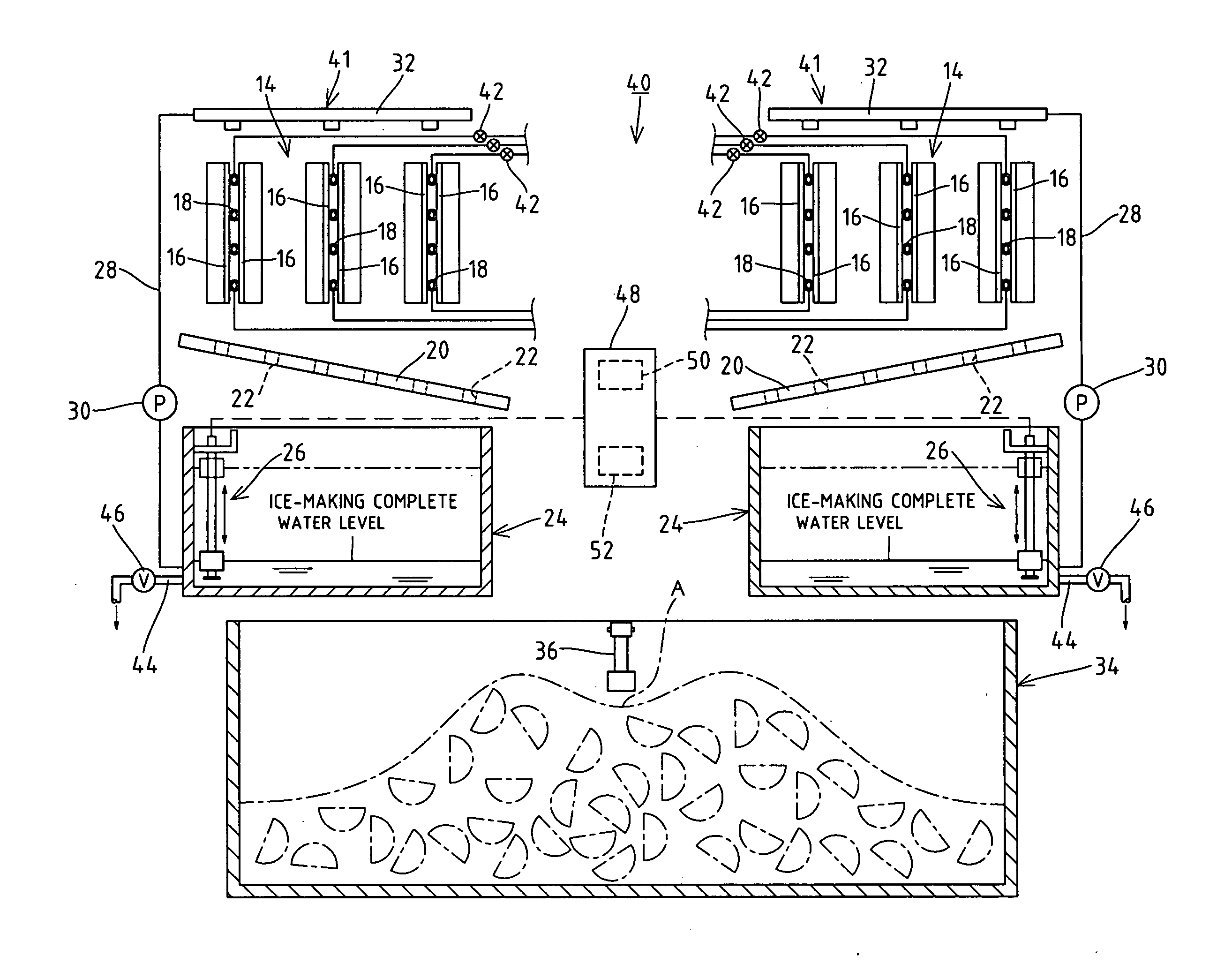

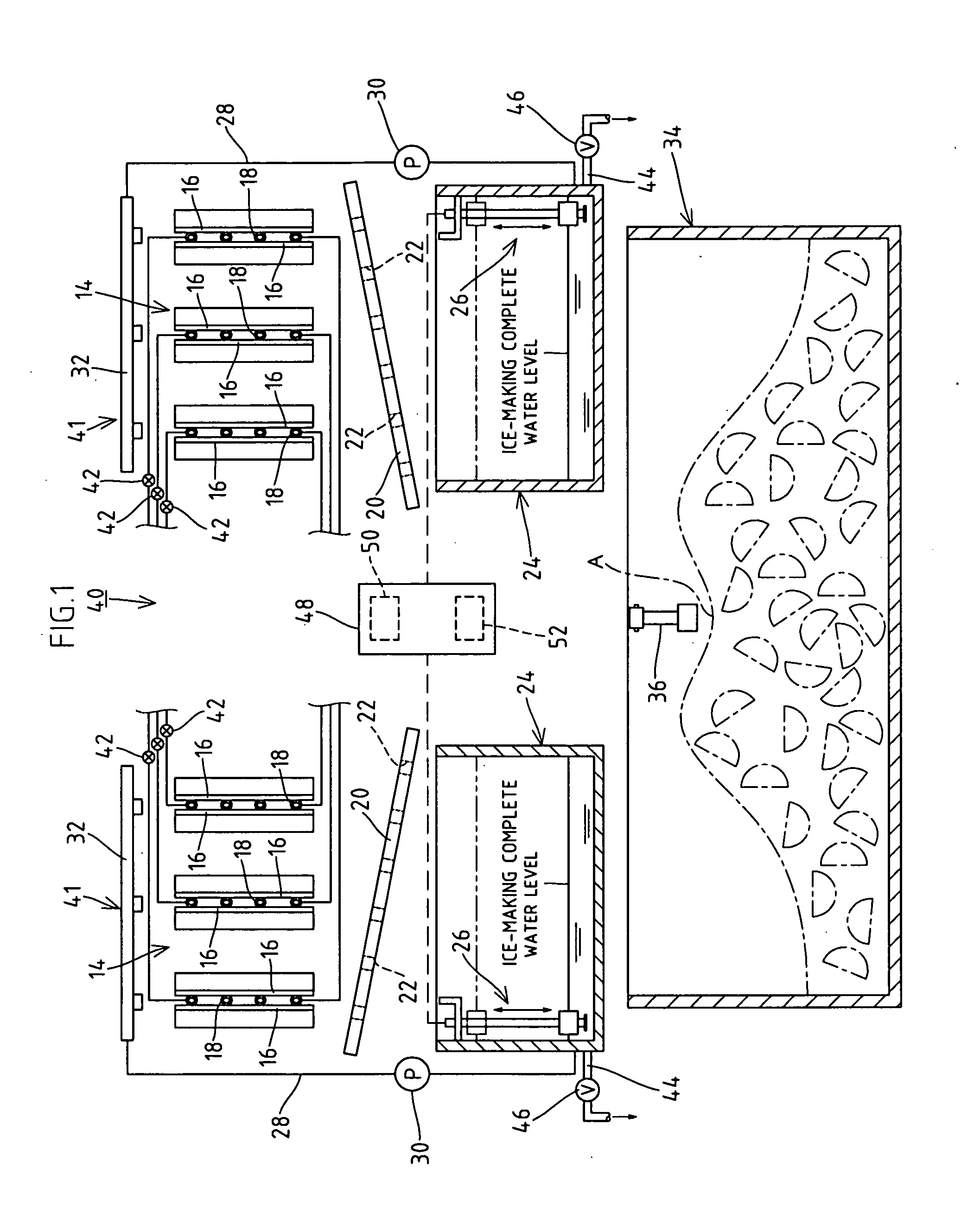

[0030]Next, the operation of the down flow type ice making machine 40 according to the embodiment will be described referring to a flowchart in FIG. 2. First, a description will be given of the normal case. At the time of the ice making operation, the circulation pumps 30, 30 of both ice making units 41, 41 are actuated to feed the ice-making waters in the ice-making water tanks 24, 24 to the ice-making surfaces of the individual ice making parts 14 via the ice-making water supply pipes 28, 28 and the ice-making water spray pipes 32, 32. A refrigerant is supplied to each evaporation tube 18 from the freezing system to cool down the ice making part 14. At this time, the control means 48 actuates the second timer 52 to start measuring the ice-making completion time upon initiation of the ice making operation (step S1). The ice-making water supplied to each ice making part 14 exchanges heat with the ice-making surface while flowing down on the ice-making surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com