Metal and metal oxide nanoparticle-embedded composites

a metal oxide and composite technology, applied in the field of metal and metal oxide nanoparticleembedded composites, can solve the problems of mechanical weakness and intolerance to organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082]The present invention is a method and apparatus that synthesizes metal / metal oxide nanoparticle-embedded in composites, such as PDMS composites.

[0083]While the making and / or using of various embodiments of the present invention are discussed below, it should be appreciated that the present invention provides many applicable inventive concepts that may be embodied in a variety of specific contexts. The specific embodiments discussed herein are merely illustrative of specific ways to make and / or use the invention and are not intended to delimit the scope of the invention.

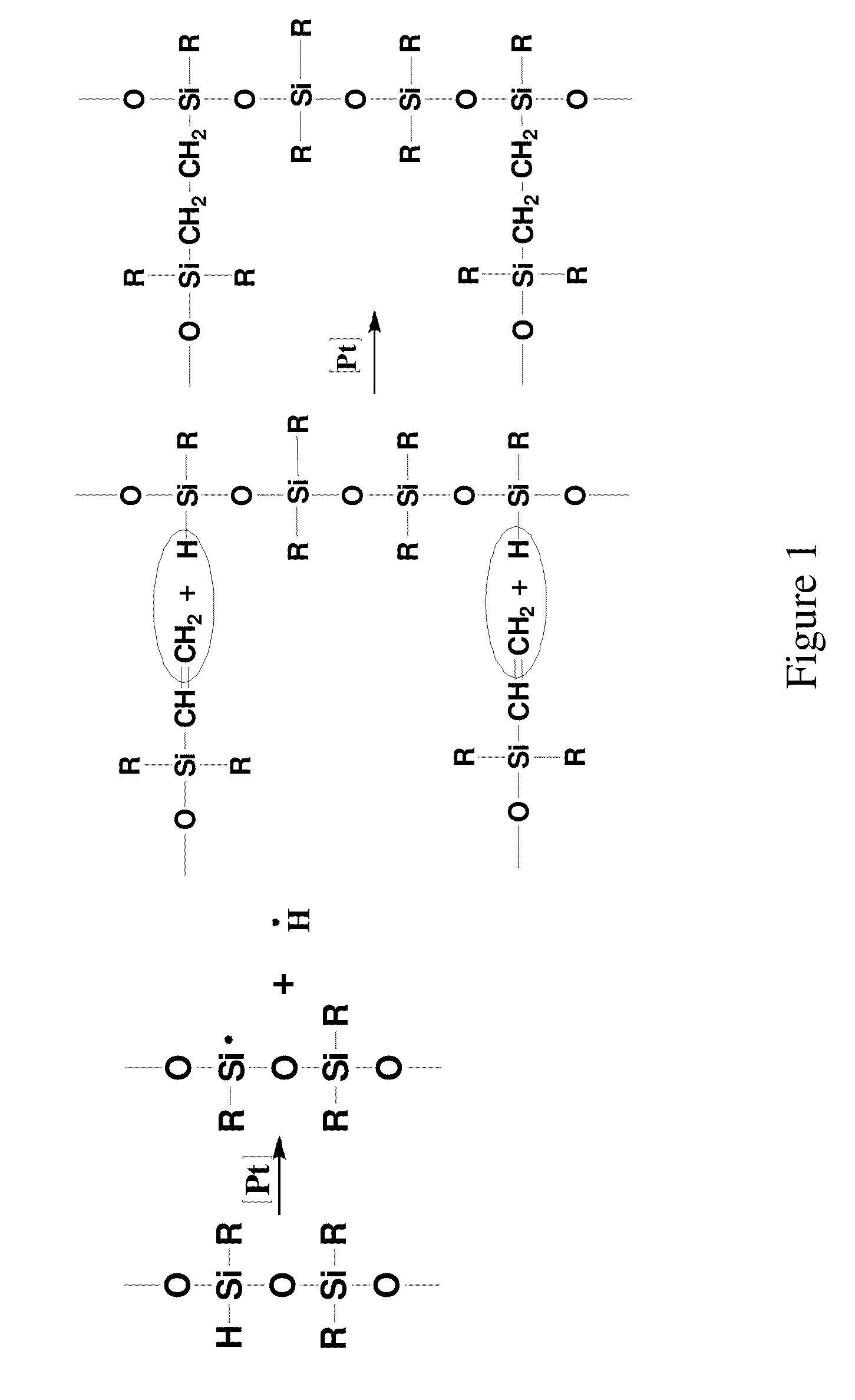

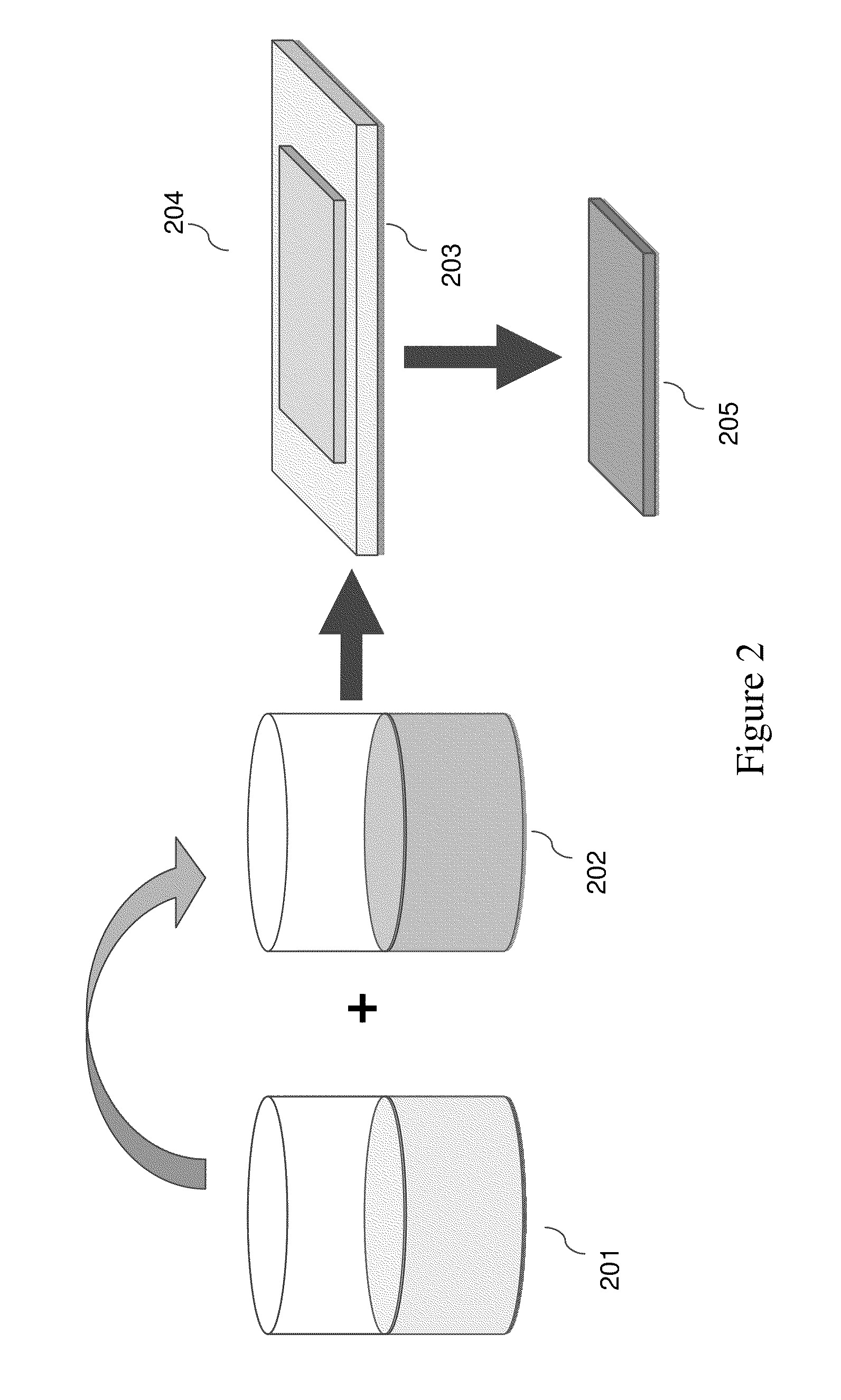

[0084]The present invention circumvents the need of using pre-formed nanoparticles and gives a bulk dispersion of nanoparticles without requiring any external reducing or stabilizing agent. The process involves adding a metal salt to a mixture of (a) a polymerizable material (i.e., a monomer, a oligomer, and / or a polymer, such as a siloxane elastomer) and (b) a polymerizing agent (such as curing agent / hardener)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com