Flow diverters to enhance heat sink performance

a heat sink and flow diverter technology, applied in the field of heat sinks, can solve the problems of liquid cooling adding significant costs and reliability concerns to system design, components dispersing, and air-cooled heat sinks becoming inadequate to sufficiently cool these devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

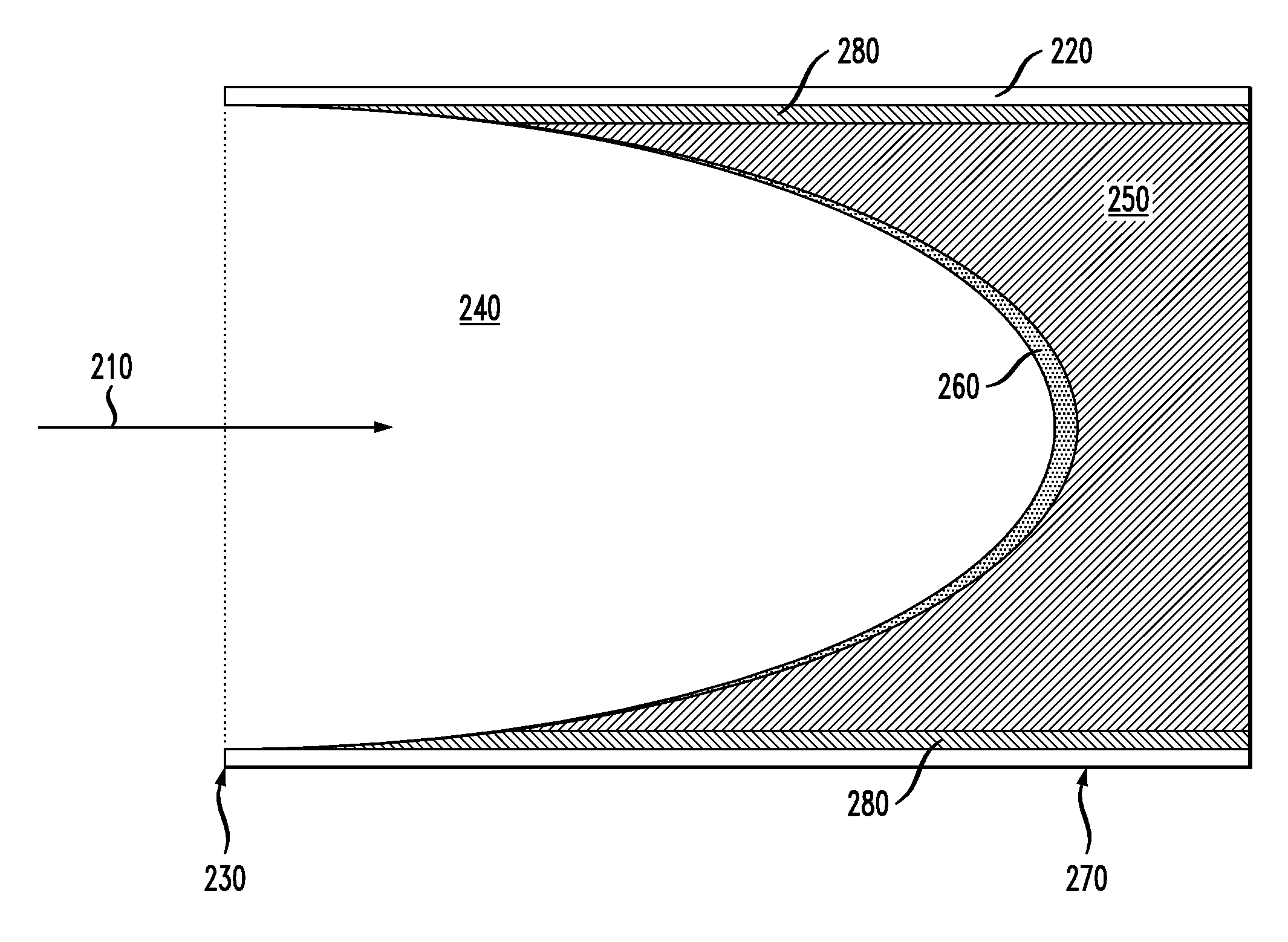

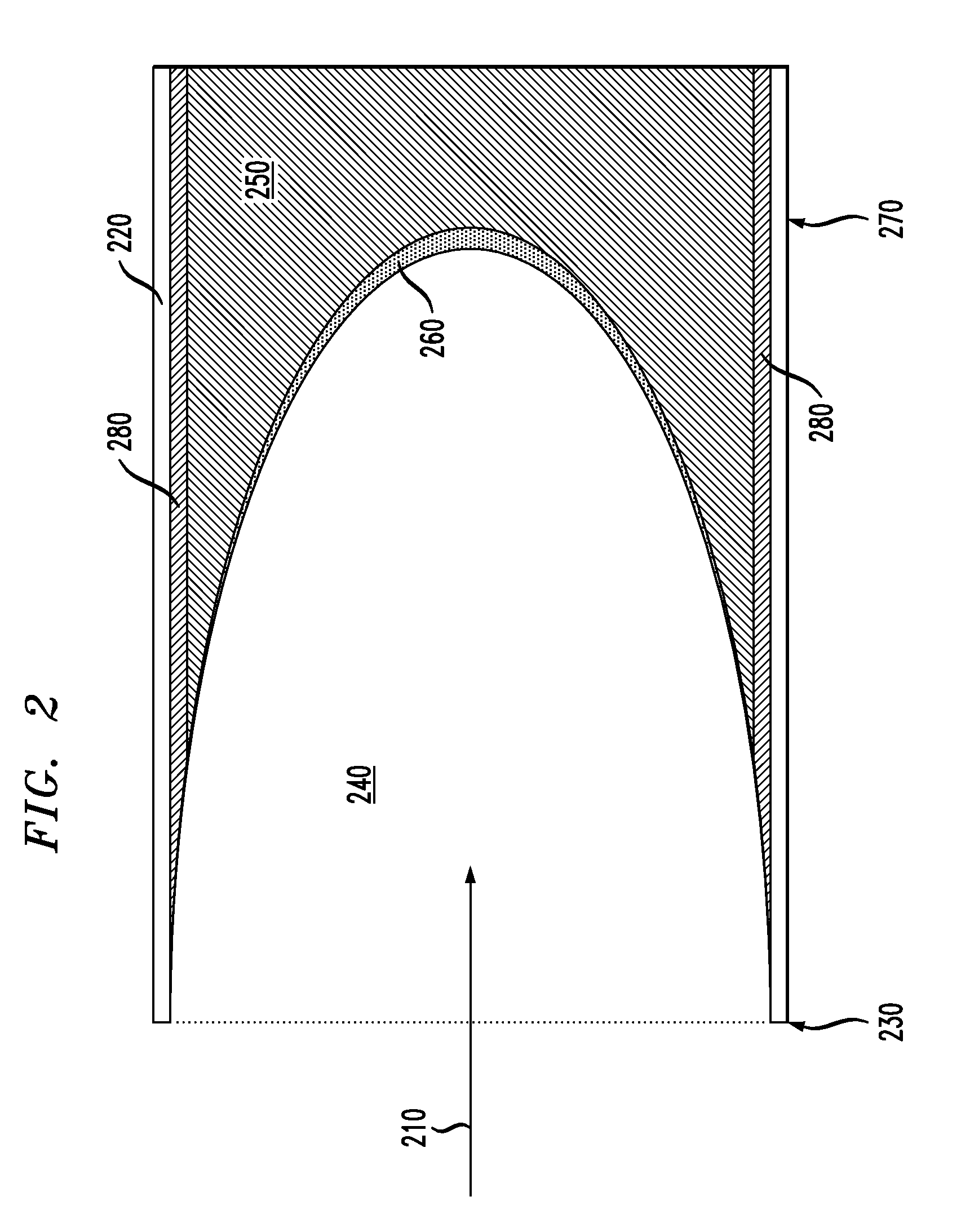

[0011]Embodiments described herein reflect the recognition that structural features may be used in heat sinks that decrease thermal resistance between the heat sink and a fluid e.g., air. In some embodiments, these structural features may be used to produce unsteady flow of air, e.g., in selected portions of the heat sink to disturb laminar flow near surfaces of the heat sink. In other embodiments, features are formed that direct cooler, faster moving air from one region of a heat sink to a region having hotter, slower flow to increase the rate of heat transfer from the hotter regions. In some embodiments, three dimensional (3-D) rendering and investment casting may be employed to form such structural features in a cost-effective manner.

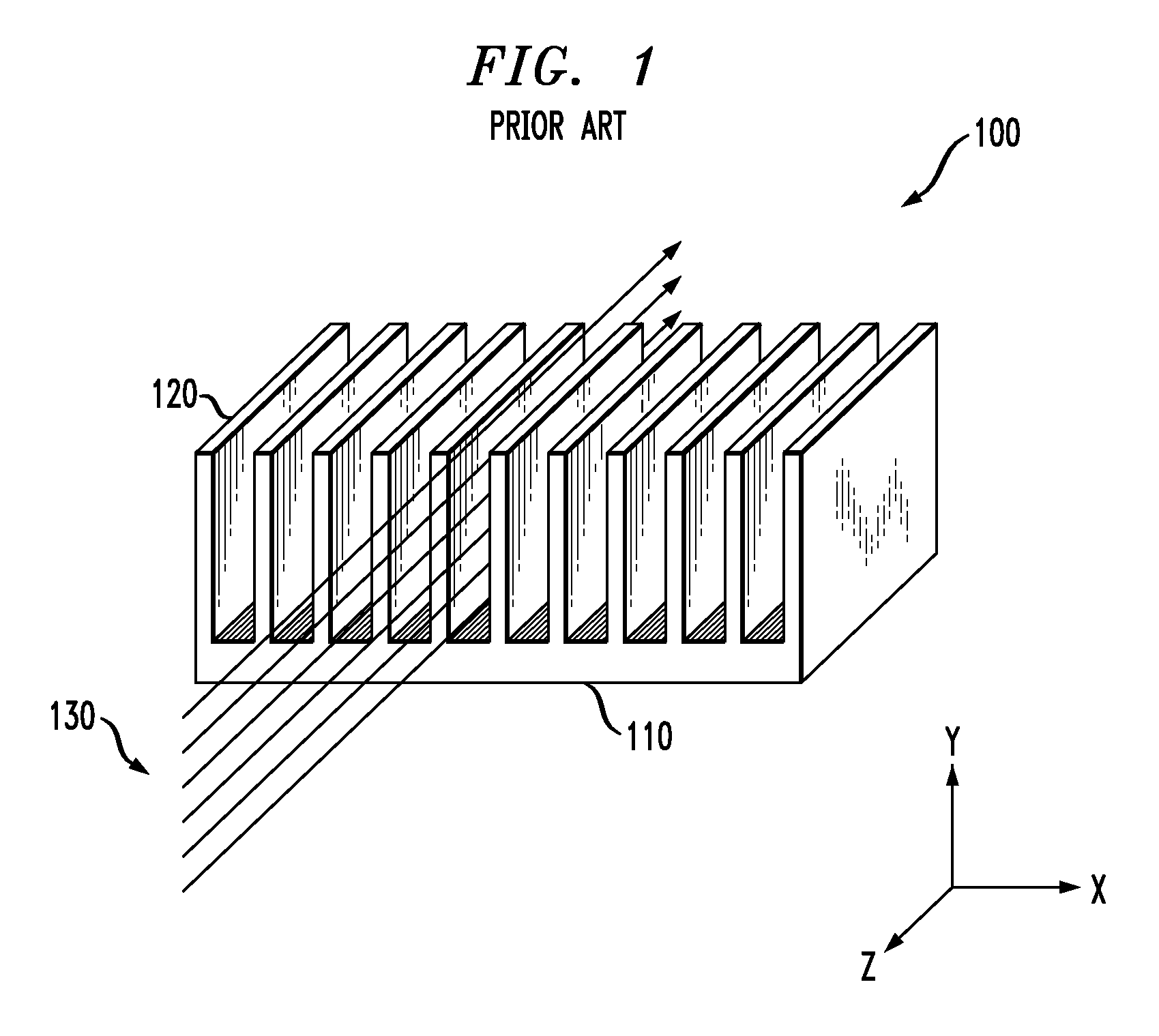

[0012]FIG. 1 illustrates a prior art heat sink 100. Features of the heat sink 100 include a base 110 and fins 120. The fins 120 of such heat sinks are typically structurally uniform, e.g., there are no projections or depressions in the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reynolds number | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com