Control-cage, a centrifugal shot-blasting device, and a centrifugal shot-blasting device for throwing abrasive grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

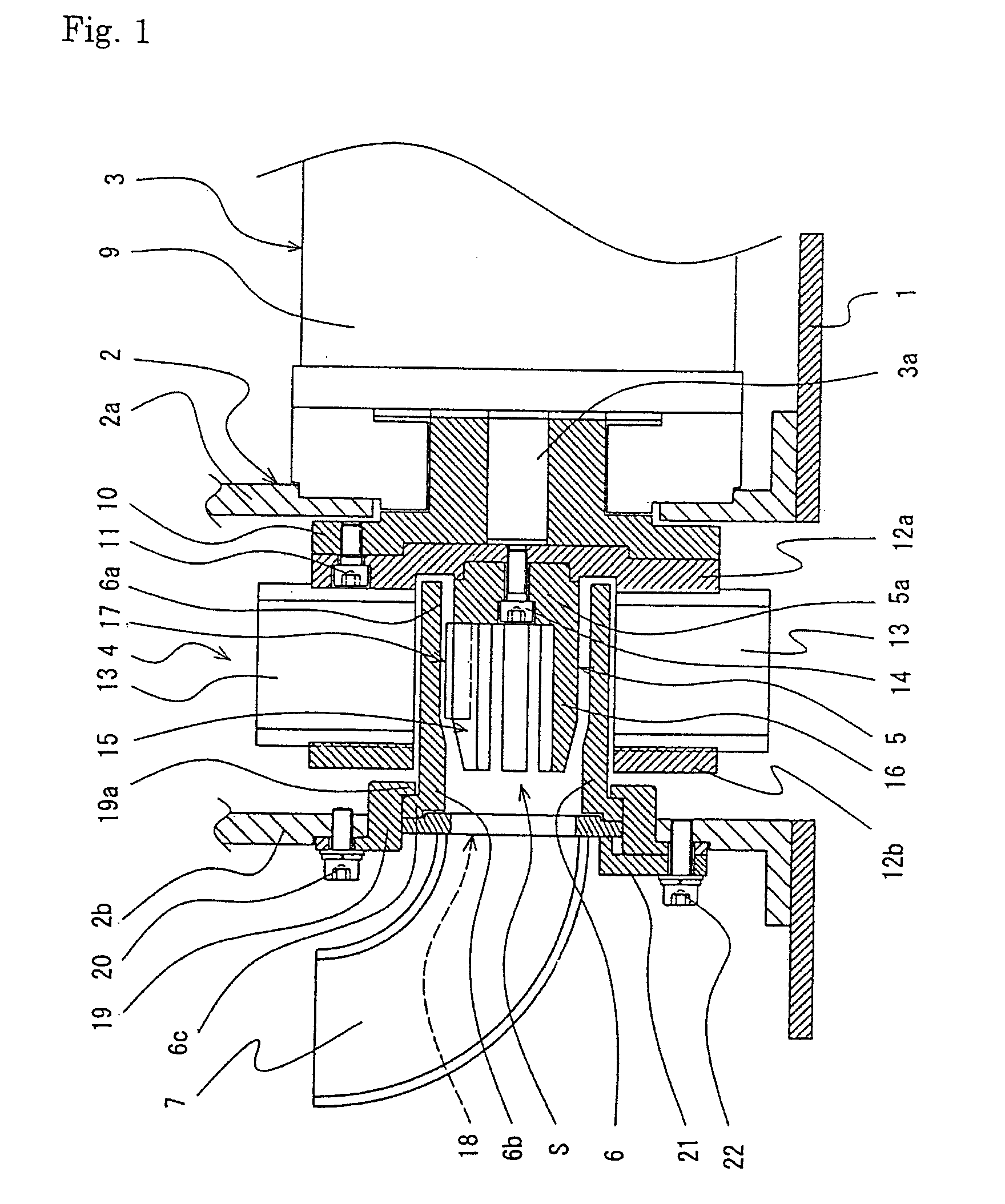

[0028]Now we discuss a control-cage and a centrifugal shot-blasting device using this control-cage, by referring to the drawings. As in FIG. 1, the centrifugal shot-blasting device of the present invention comprises a housing (impeller case) 2, a driving means 3, an impeller 4, a distributor 5, a control-cage 6, and an inlet tube 7. The housing 2 is placed on an upper wall 1 of a polishing chamber for the device. The driving means 3 is placed on the wall 1 and installed outside a lateral side 2a of the housing 2. The impeller 4 is fitted onto the driving shaft 3a of the driving means 3. The distributor 5 is placed in a space S that is inside the impeller 4. The distributor 5 is positioned coaxially with the driving shaft 3a. The control-cage 6 is fixed on the opposite lateral side 2b of the side 2a of the housing 2. The inlet tube is fixed on the side 2b of the housing 2.

[0029]The driving means 3 may be a driving motor that has a bearing (not shown). The bearing rotatably supports t...

example

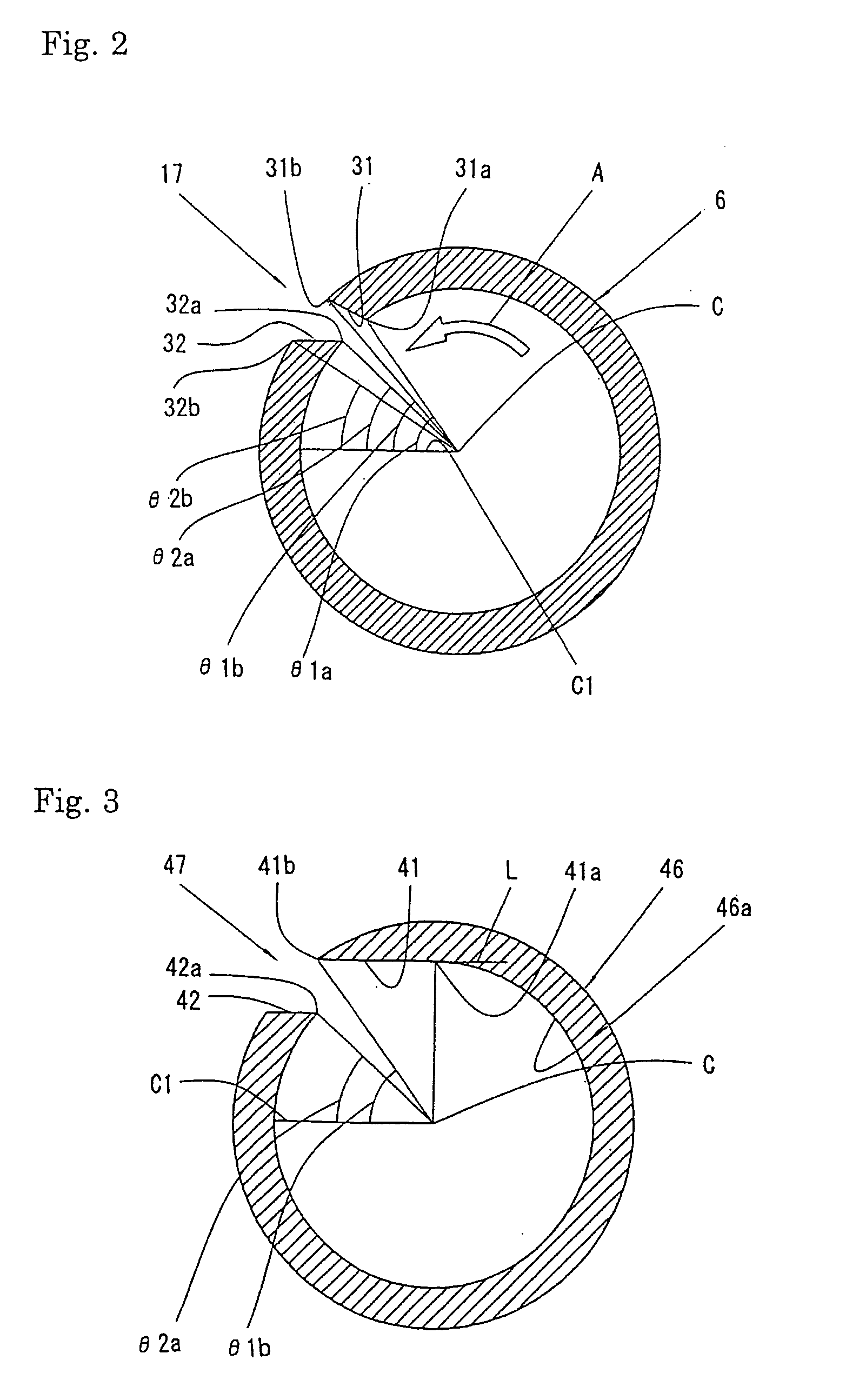

[0040]In this example, as in FIG. 3, a centrifugal shot-blasting device using a control-cage was used. The control-cage has an opening that has an upstream wall 41 and a downstream wall 42. These walls are parallel. Also, the walls are made so that the difference Δθ (=θ1b−θ2a) between the angles θ1b and θ2a is zero. The angle θ1b is measured from the plane C1, containing the central axis C, to the outer edge 41b of the upstream wall 41. The angle θ2a is measured from the plane C1, containing the central axis C, to the inner edge 42a of the downstream wall 42. A test of throwing by this device using SB10 (shot-blasting media made by Sintobrater Co., Ltd.), having an average diameter of 1 mm was carried out, and their distribution (an example) was examined. The result is shown in FIG. 4. The same test of throwing by a device using two conventional types of a control-cage was carried out. One cage had an opening of which the shape of the triangle or the quadrangle is like the Japanese ...

embodiment 2

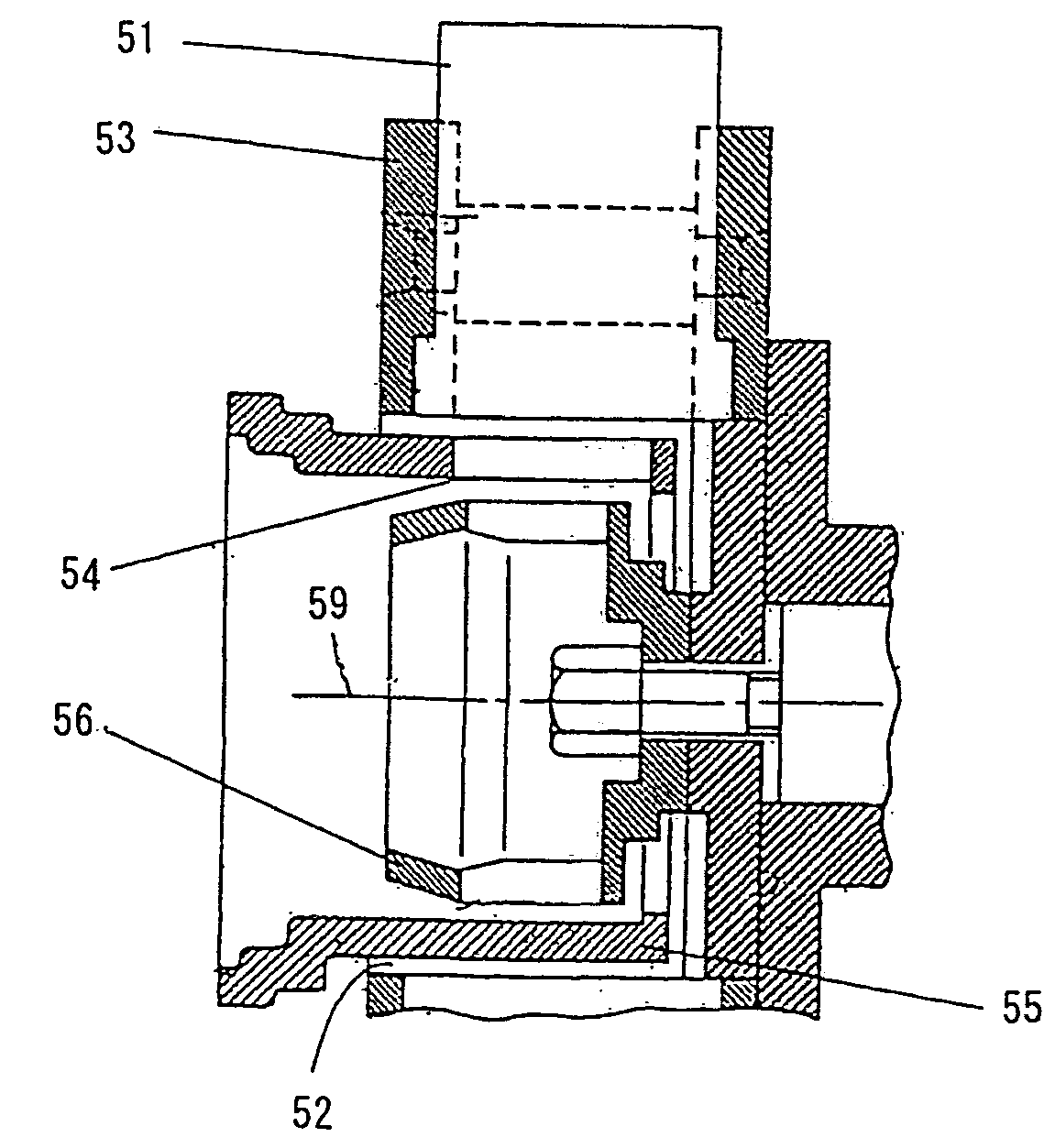

[0043]Now, we discuss an embodiment of the centrifugal shot-blasting device for throwing abrasive grains of the present invention, by referring to FIGS. 6-10. The device comprises an impeller 53, a control-cage 55, and a distributor 56, as in FIG. 8. The impeller 53 is rotatably installed in the device, has a plurality of blades in a radial pattern, and has a cylindrical space 52 in its center. The control-cage 55 is placed in the cylindrical space 52, has a shape of a hollow cylinder, and has an opening 54 for an exit of the abrasive grains, on its lateral side. The distributor 56 is installed in the hollow space of the cage 55 so that it can rotate with the impeller 53.

[0044]The exit of the abrasive grains 54 on the control-cage 55 is approximately an elongated slit that has a given width and that is parallel to the central axis 59 of the control-cage 55, as in FIG. 7. As in FIG. 6, it has an inner wall (upstream wall) 58, which is located opposite (upstream of) the direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com