Plate material conveying device

a technology of conveying device and plate material, which is applied in the direction of thin material handling, article separation, gripping head, etc., can solve the problems that the suction type holders may not hold the remainder of materials, and achieve the effect of reducing time required, efficient conveying, and increasing the speed of plate material conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

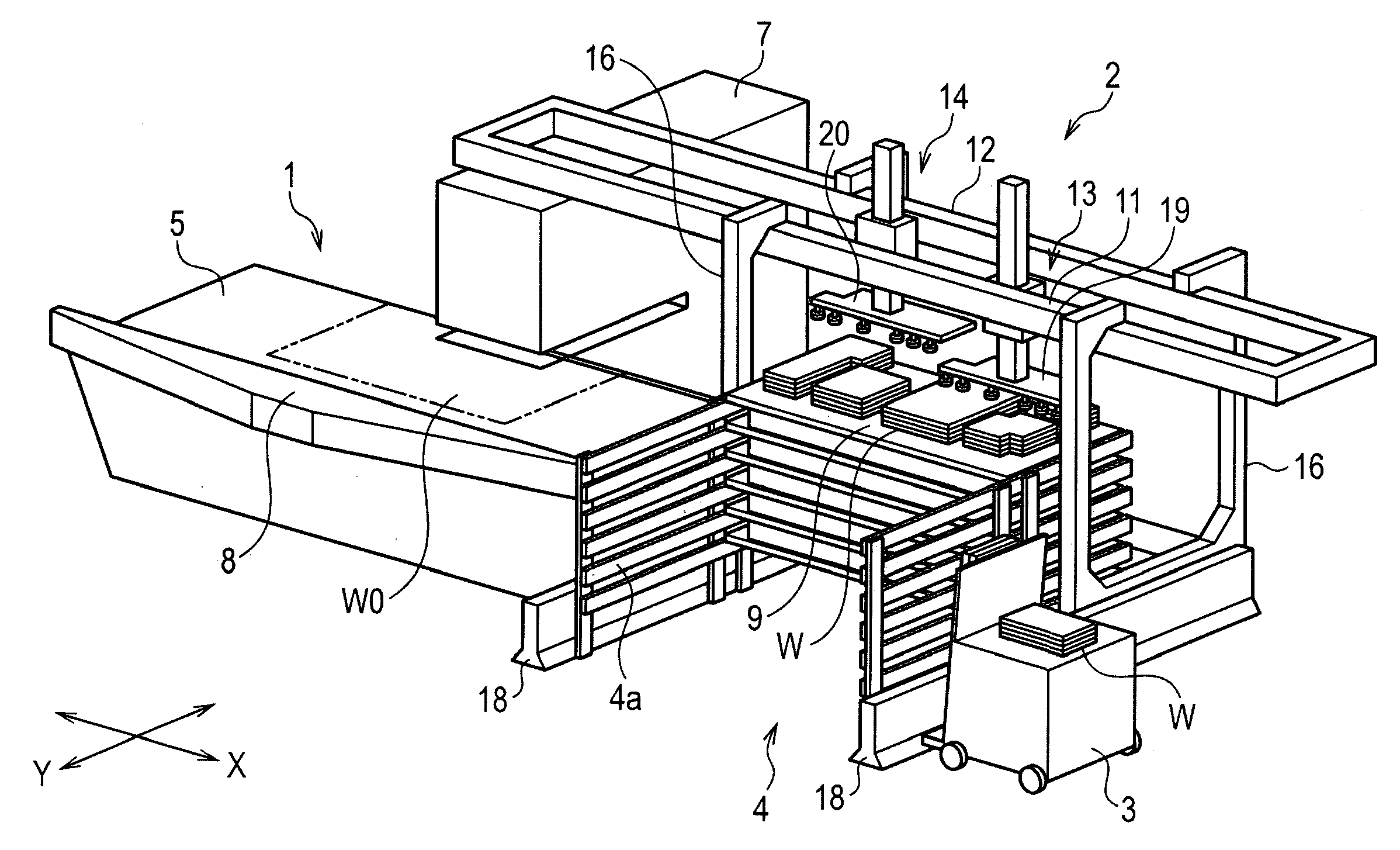

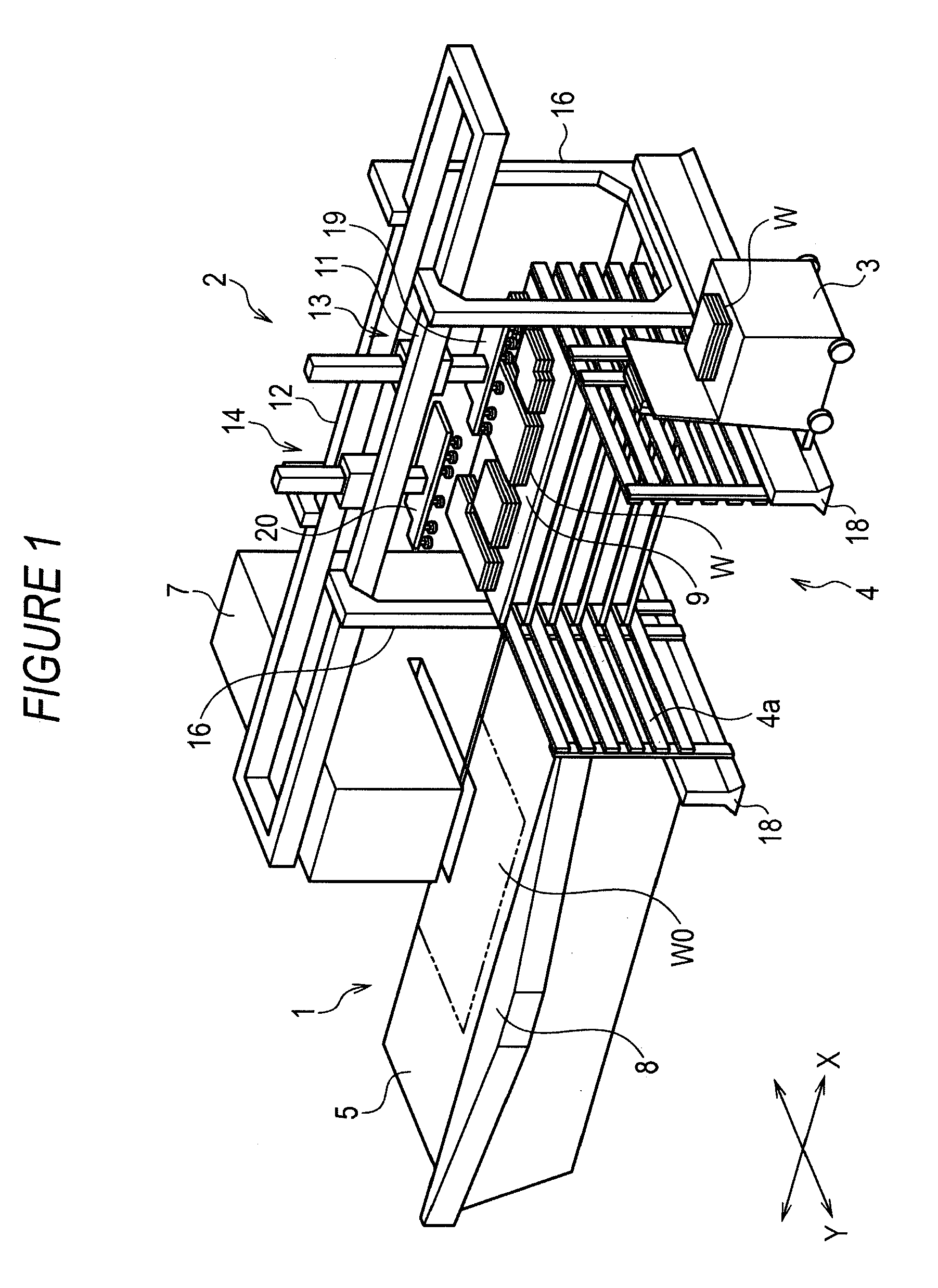

[0034]An embodiment of the present invention will be described with reference to FIGS. 1 to 13. FIG. 1 is a perspective view of a plate material processing system as a whole including a plate material processing machine 1, a plate material conveying device 2, a pallet 9 and a plate material transport vehicle 3 both serving as a plate material placement portion, and a plate material stocker 4. The plate material processing system further includes a plate material carry-in device (not shown in the drawings) that carries a raw plate material W0 into the plate material processing machine 1. However, description of the plate material carry-in device is omitted. The plate material processing machine 1 and the plate material conveying device 2 are controlled by a computerized processor control device and a computerized conveyance control device (not shown in the drawings), respectively, according to respective control programs.

[0035]The plate material processing machine 1 provides the func...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com