Pillow Packaging Bag, Pillow Type Packaged Body, Heat Seal Bar for Pillow Packaging Machine, and Pillow Packaging Machine

a pillow packaging machine and heat seal technology, applied in the field of pillow packaging bags, can solve the problems of difficult machining of seal bars, major problems such as piercing or scratching mutually adjacent pillow packaging bags, and achieve the effect of excelling in the ability to seal off foreign matter, avoiding fluctuations in the thickness of seal portions, and avoiding major problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

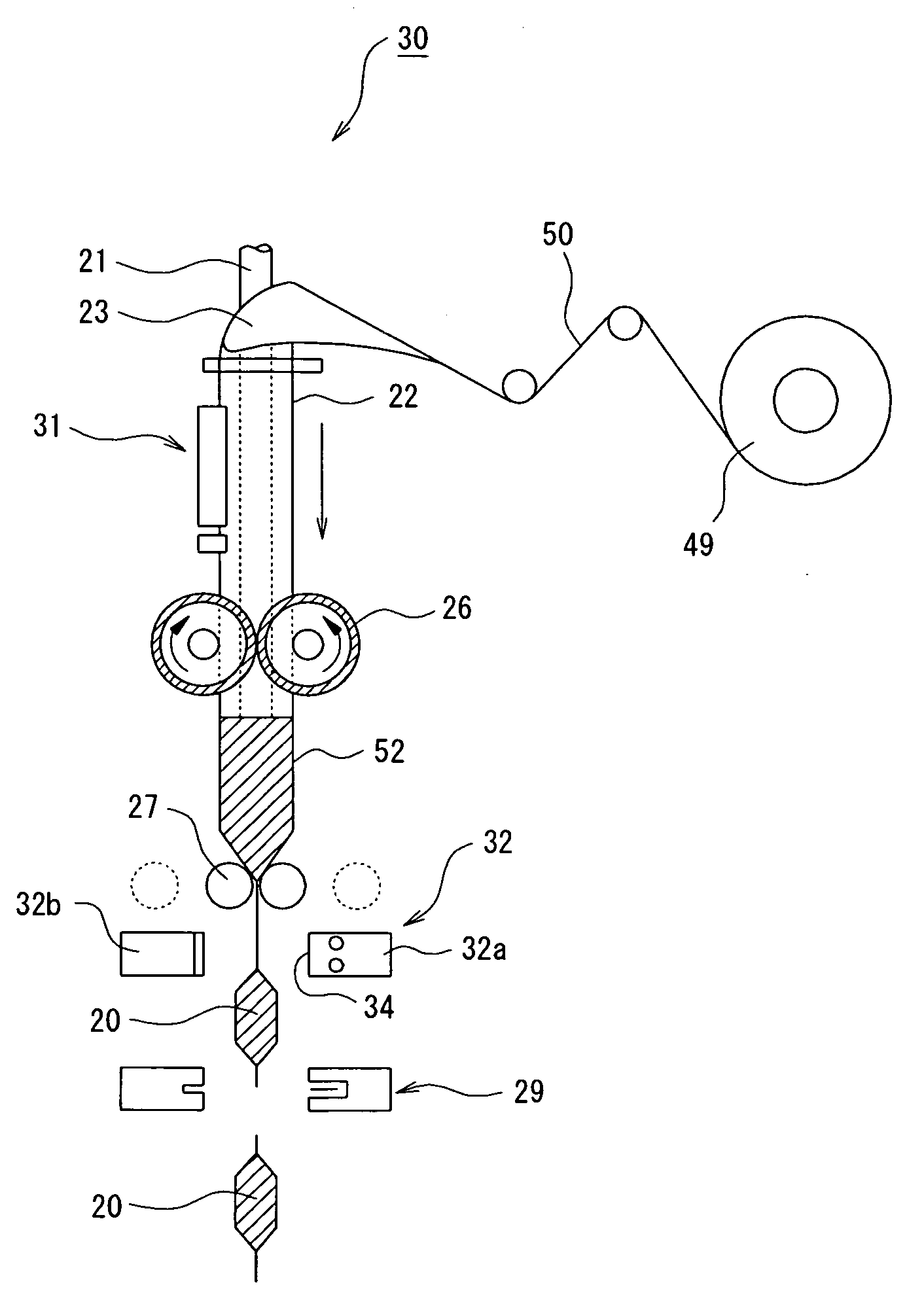

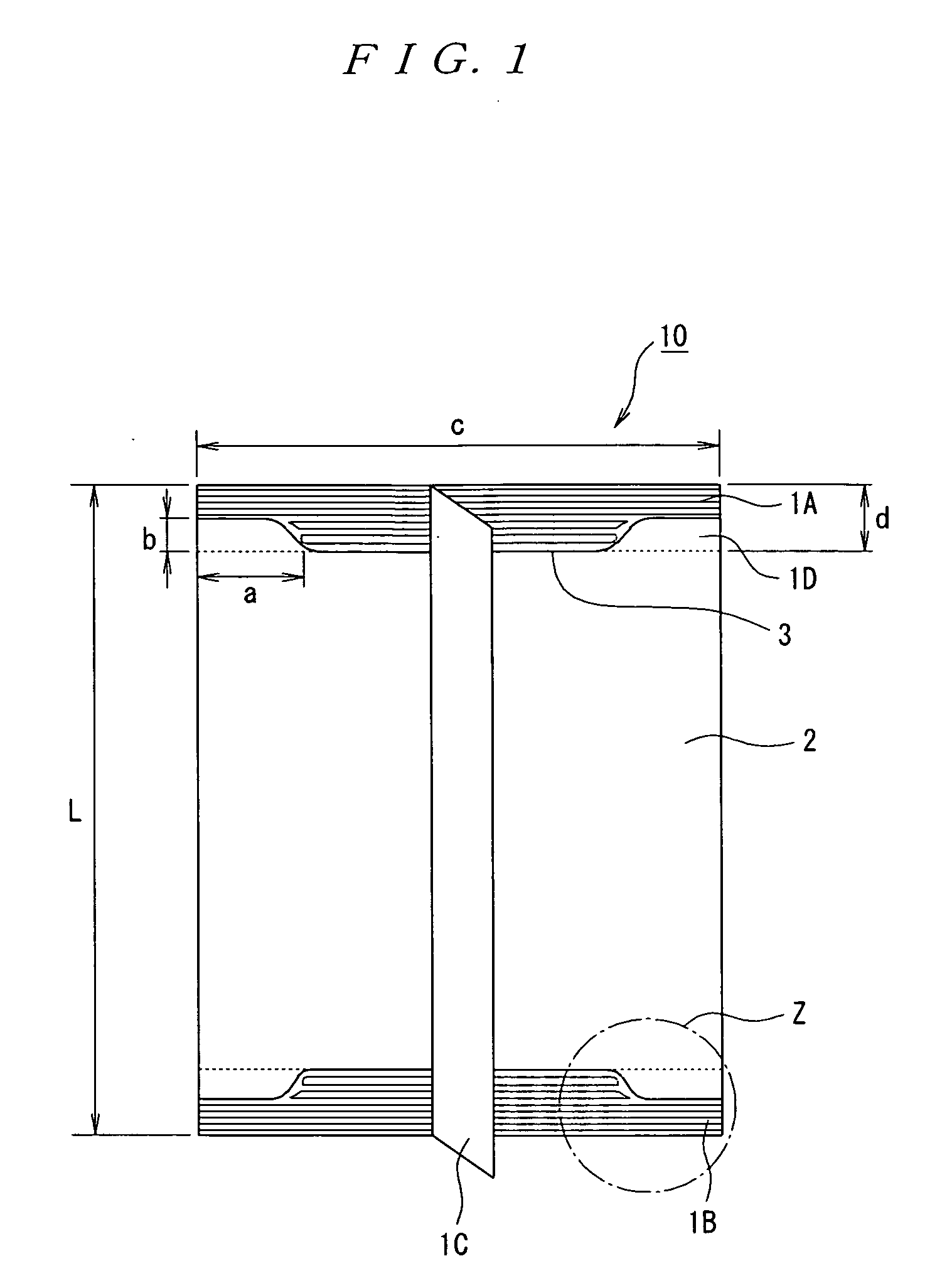

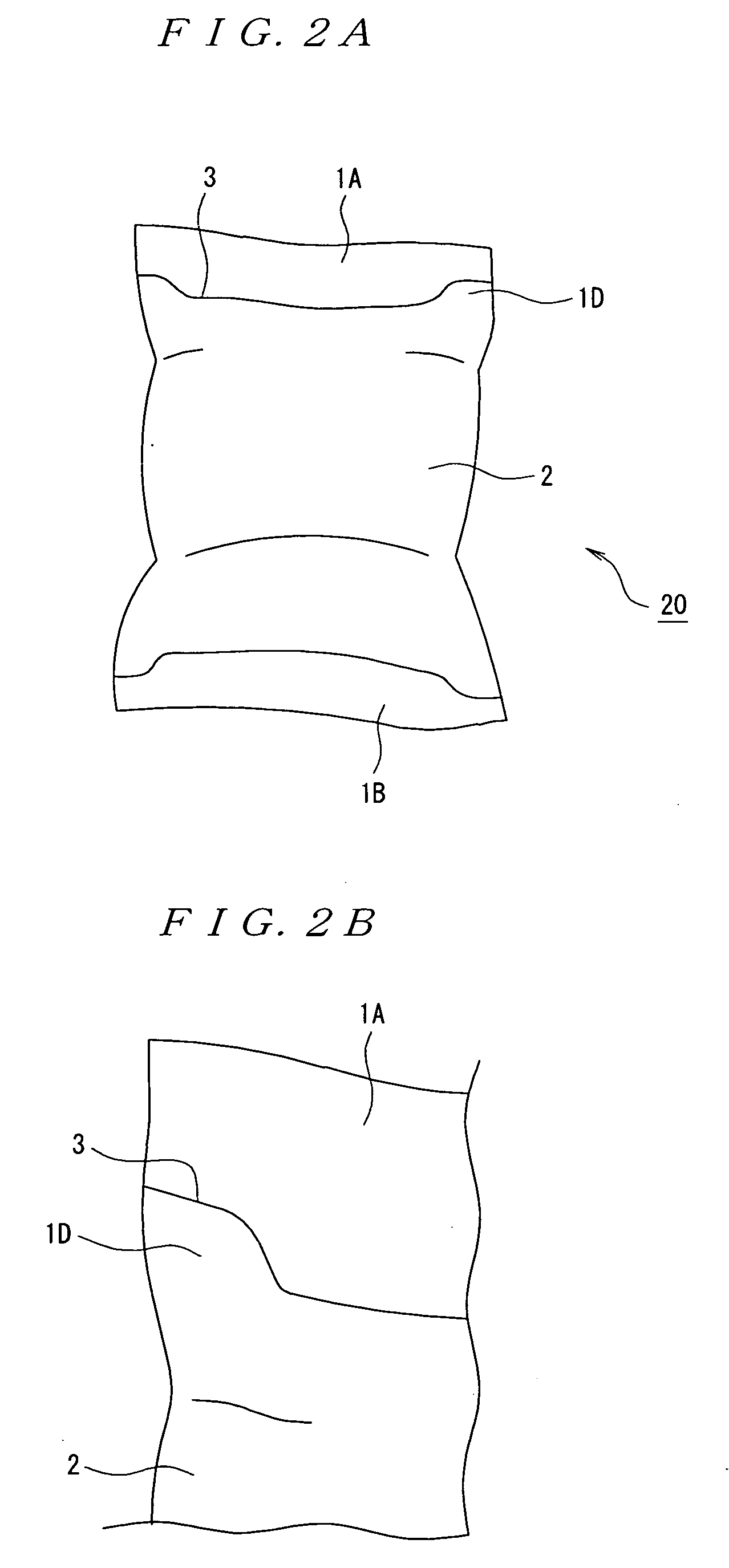

embodiment 1

[0101]A laminated film wound in a 120 mm-wide roll (biaxially oriented polyester (12 μm) / adhesive / non-extensible polyethylene (25 μm) / straight-chain low-density polyethylene (25 μm): 62 μm in total film thickness) was put to a continuous vertical packing machine ONP2030 (a product of Orihiro Co., Ltd.), and first vertically sealed with a sealing plate at 180° C. to be fabricated into cylindrical bags. Then, after being subjected to heat sealing of the lower lateral seal with a sealing plate at 180° C. for a width of 30 mm (for two bags), the bags were filled with 22 g each of agar at 70° C., which was the content, and the lateral seal for sealing the upper opening was heat sealed for a width of 30 mm (for two bags).

[0102]Finally, the bag was cut at the center of the lower lateral seal portion, and pillow type packaged bodies of 15 mm in lateral sealing width were prepared. By using a lateral sealing bar whose a and b dimensions (a, b) [mm] in the buffering region at both side ends o...

embodiment 2

[0108]Pillow type packaged bodies were prepared by using a heat sealing bar whose dimensions (a, b) [mm] of the buffering regions 1D were (7, 3) in the same way as Embodiment 1 except that the content volume was varied from 22, 32, 27, 17 and 12 g, and the results of similar vibration test and drop test to those for Embodiment 1 were evaluated. The results of evaluation, together the filling rate of each pillow type packaged body obtained from Formula (6), are collectively shown in FIG. 13. Incidentally, the maximum content volume required for figuring out the filling rate was supposed to be 32 g according to the following formula of calculation, with the density of agar being supposed to be 1 g / cm3.

[0109]It is evident from the results shown in FIG. 13 that the probability of sealing failure is high at a filling rate of over 85% and that the probability of pin hole occurrence due to the folding or bending of lateral seal portions is high at a filling rate of below 50%. Thus it is se...

embodiment 3

[0114]A laminated film wound in a 220 mm-wide roll (biaxially oriented polyamide (15 μm) / adhesive / straight-chain low-density polyethylene (60 μm): (75 μm) in total film thickness was put to a continuous vertical packing machine ONP2030 (a product of Orihiro Co., Ltd.), and first vertically sealed with a sealing plate at 180° C. to be fabricated into cylindrical bags. Then, after being subjected to heat sealing of the lower lateral seal with a sealing plate at 180° C. for a width of 40 mm (for two bags), the bags were filled with 200 g each of water, which was the content. The lateral seal for sealing the upper unsealed part was heat sealed for a width of 40 mm (for two bags). Finally, the bag was cut at the center of the lower lateral seal portion, and pillow type packaged bodies of 20 mm in lateral sealing width were prepared. The lateral sealing plate used then had a lateral sealing bar whose dimensions a and b at both side ends of the lateral seal portions then were 8 mm each, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com