Phase Change Fluid Spring and Method for Use of Same

a fluid spring and phase change technology, applied in the field of fluid springs, can solve the problems of high pressure at the surface, commercially unreasonable or impractical to charge the fluid springs to these pressures at the surface, and the safety risk of operating personnel is very substantial,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

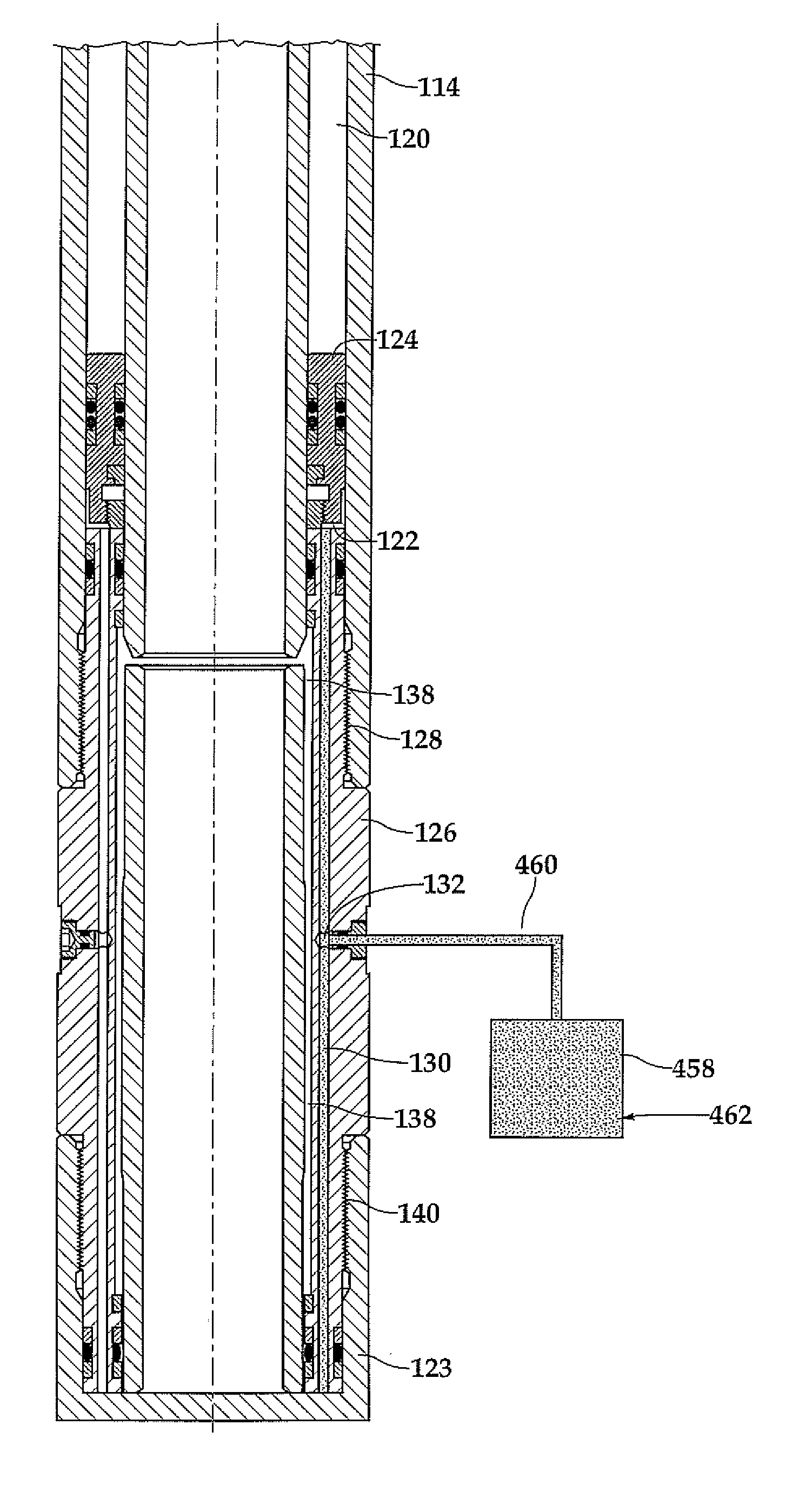

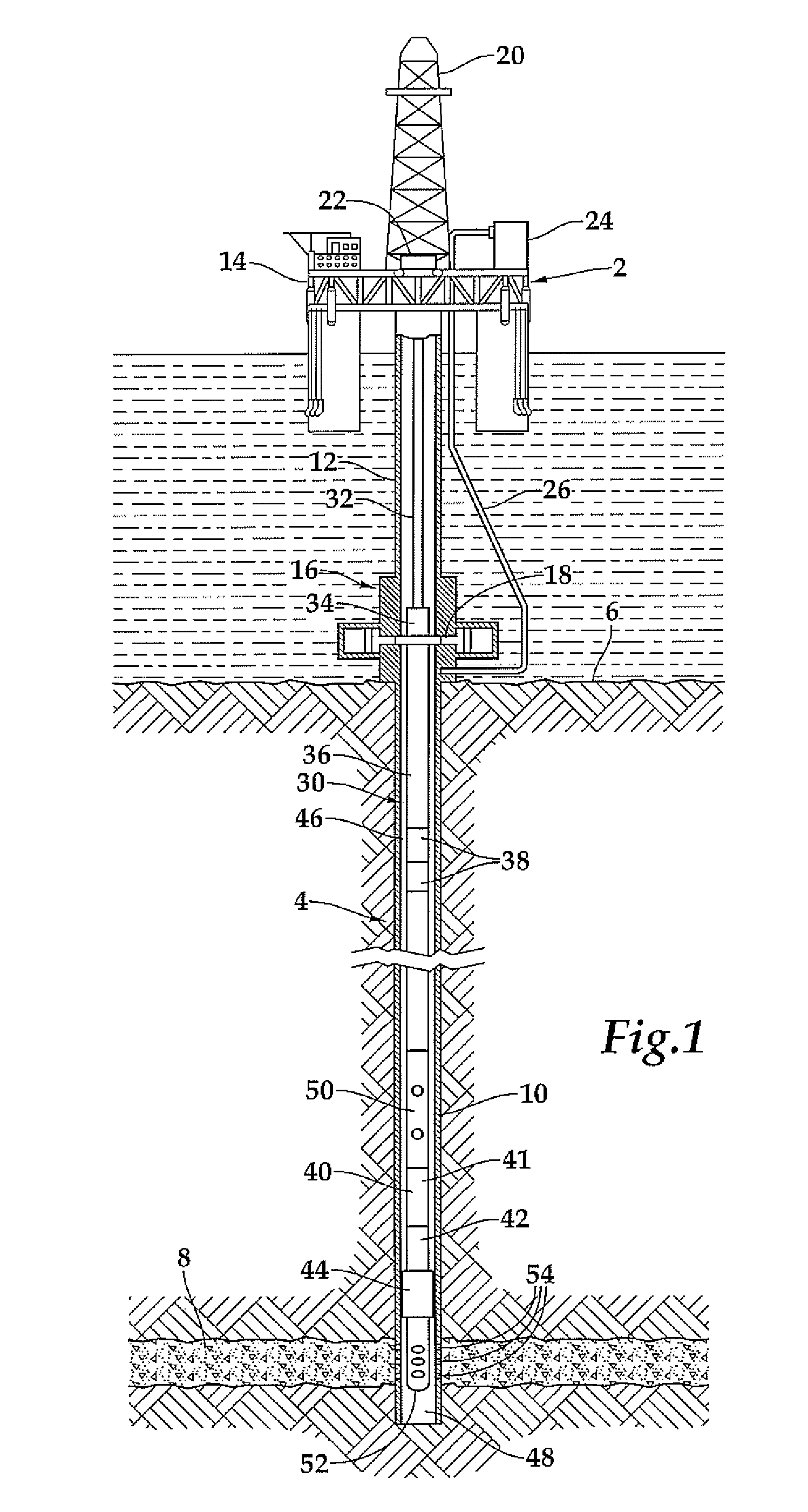

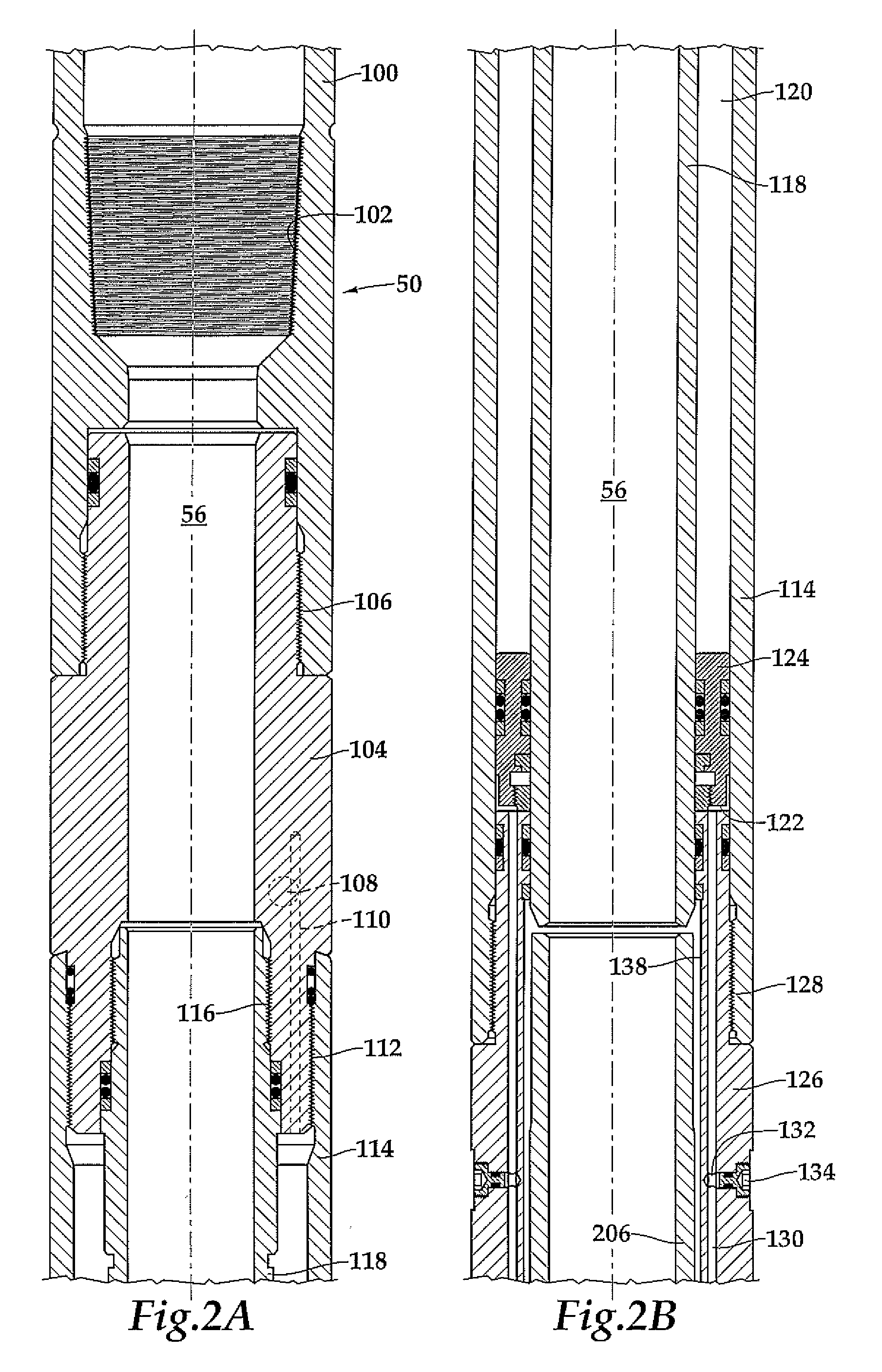

[0089]It is determined that a testing tool with phase change fluid spring 50 will be used in a particular downhole environment using a phase change fluid of carbon dioxide. The hydrostatic pressure in the annulus may be determined by the weight and / or density of the mud and the depth of the mud at which the testing toot with phase change fluid spring 50 will be used. For example, if it is determined that the hydrostatic pressure in the unpressurized annulus is approximately 10,000 psi, then the phase change fluid in the pressurized gas chamber 120 should sufficiently exceed the hydrostatic such as a pressure of at least 10,500 psi pressure. As described above, energy is stored in the phase change fluid spring 450 by compressing the phase change fluid by pressurizing the annulus using the pump 24 via the control conduit 26. In this example, the amount of phase change fluid to be charged into chamber 120 at the surface can be determined based upon the required downhole volume using th...

example 2

[0093]The desired downhole volume (V) of the phase change fluid, in this case carbon dioxide is 16 liters. The hydrostatic pressure at the desired depth is approximately 20,000 psi. The downhole temperature at the desired depth is approximately 250° C. or 523.15 K. The ideal gas law, PV=nRT, may be used to determines the required liquid volume of carbon dioxide at the surface. Using the gas constant of R=0.0821 liter·atmosphere·mole−1·K−1, it can be determined that approximately 253.49 moles of carbon dioxide are required. Charging the chamber 120 at the surface at a temperature of about 88° F. will require a pressure of at least 1,070 psi and preferably 1,500 psi to maintain the carbon dioxide in a liquid state. Liquid carbon dioxide has a density of approximately 1.03 gms / ml, thus 253.49 moles of liquid carbon dioxide, which has a molecular mass of 44.0095, will weight approximately 11,155 gms. Using the density of liquid carbon dioxide, this weight of carbon dioxide will occupy a...

example 3

[0094]In another example, the amount of phase change fluid that is charged into the phase change fluid spring 450 may determined by weight. For example, the change in weight of the phase change fluid source 454 or the phase change fluid spring 450 may be monitored to determine if the required amount of phase change fluid has been charged into the chamber 120.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com