Prefabricated containerized housing

a containerized housing and prefabricated technology, applied in special buildings, parkings, building repairs, etc., can solve the problems of early housing modules failing, shipping empty space, and availability within reach of only a limited regional mark

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

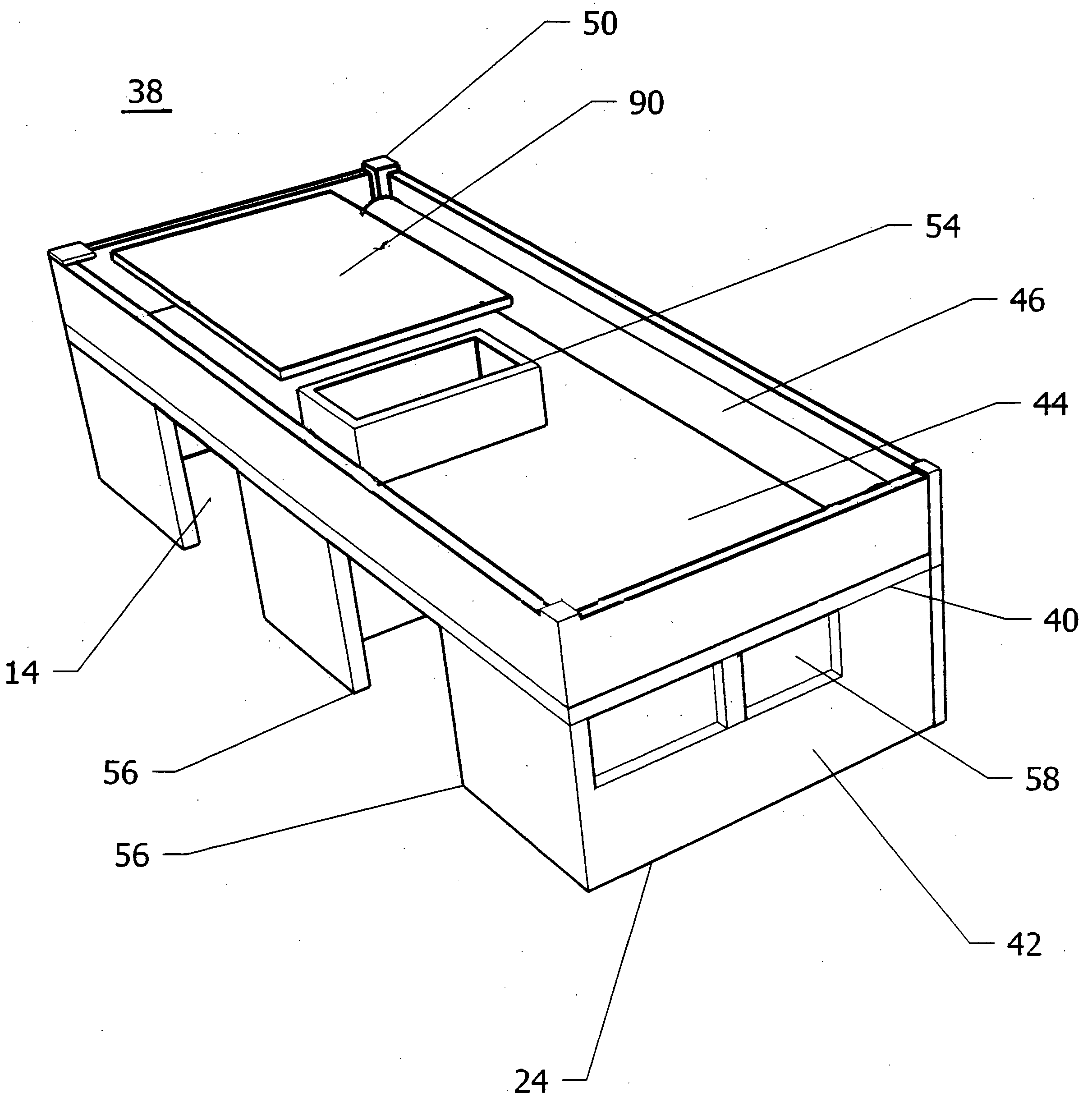

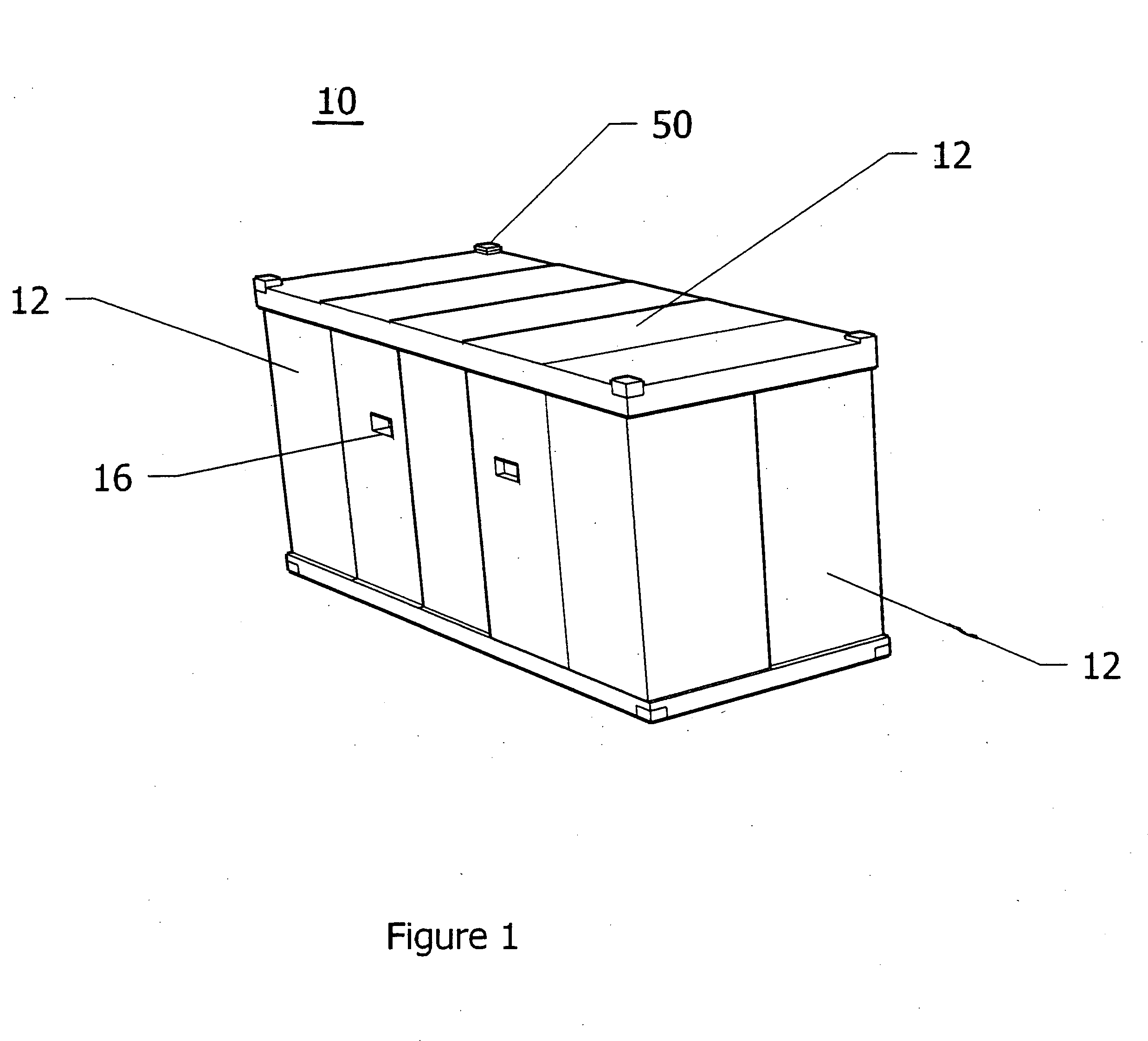

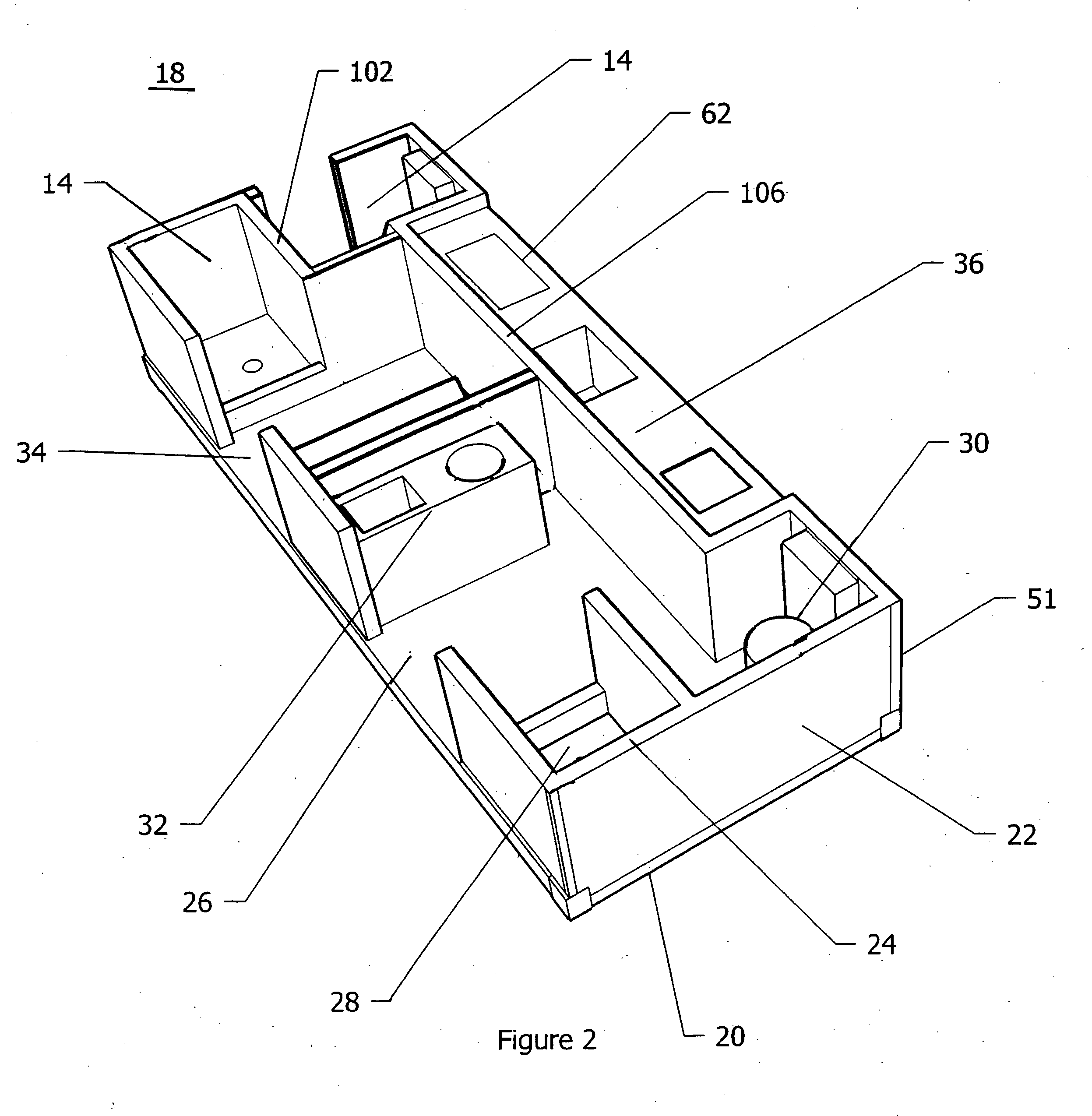

[0045]The exemplary embodiments of the single, self-contained housing core configured for containerization and related methods of construction for dwellings and systems for intermodal freight transport thereof are disclosed and discussed in terms of prefabricated housing and more particularly, in terms of low cost, sustainable dwellings and domiciles of shelter and safety. It is envisioned that the advantages of the present disclosure may be utilized for the benefit of those in need of a home and in various geographies. The housing core and transport system may be employed for domestic, regional and / or worldwide distribution. It is envisioned that the present disclosure may be used with a range of applications including those employing renewable energy and conservation techniques. It is further envisioned that the housing core is constructed to form a dwelling, which is designed to provide a shelter in a package that can be deployed by those at various skill levels including the mos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com