Swash plate compressor

a compressor and plate technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of difficult to reduce viscosity and difficult to generate heat of lubricating oil, and achieve excellent sliding characteristics and high refrigerating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

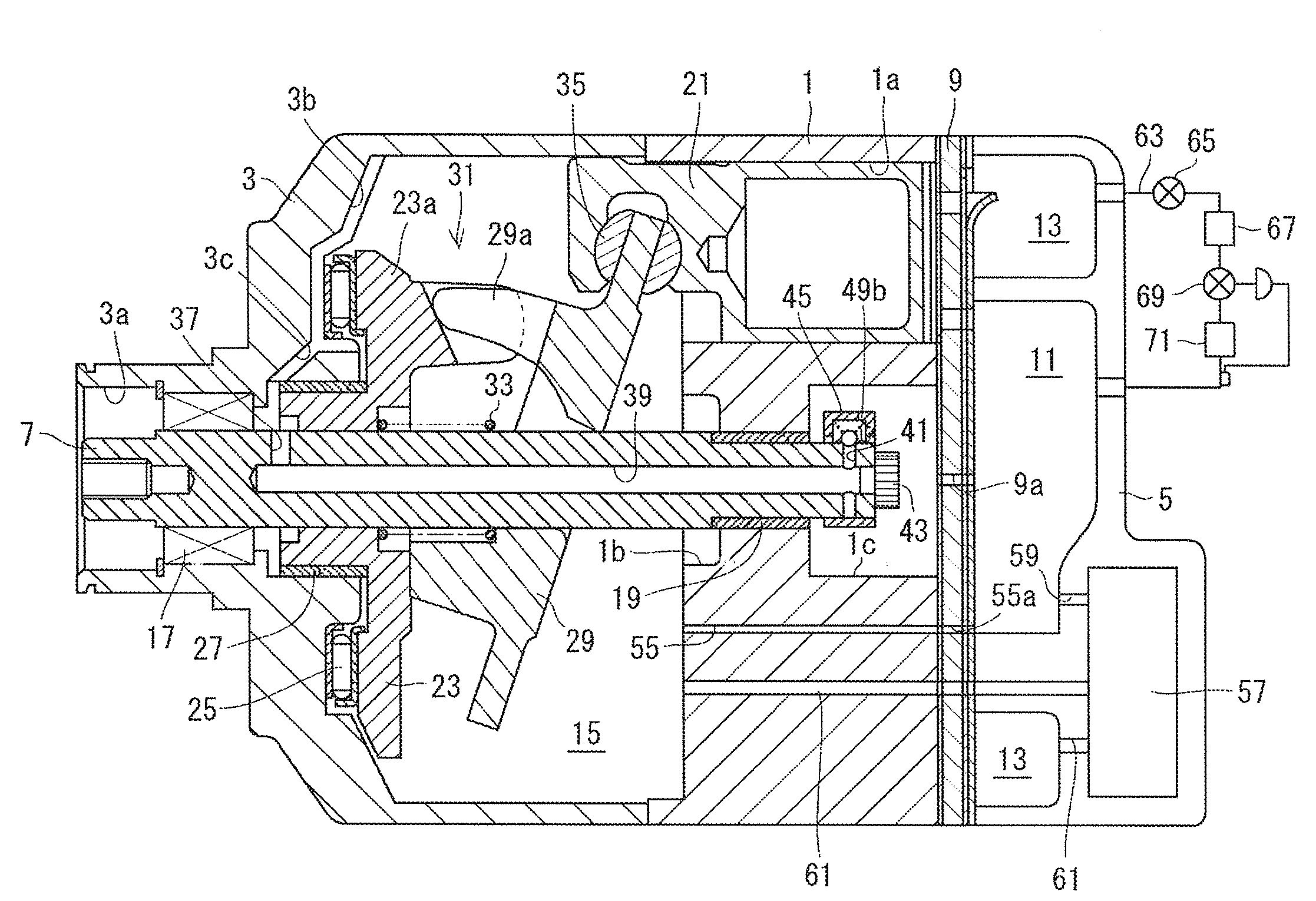

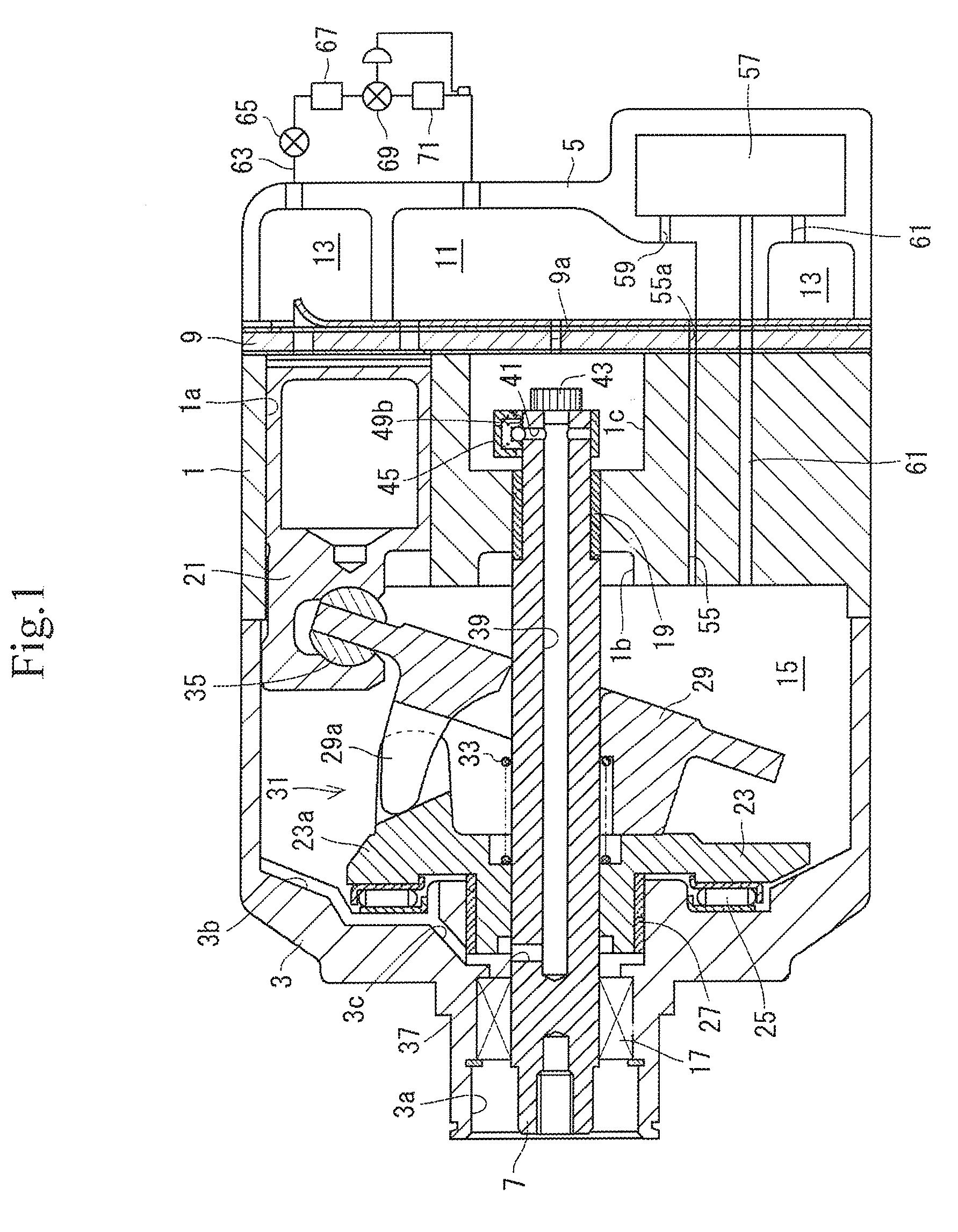

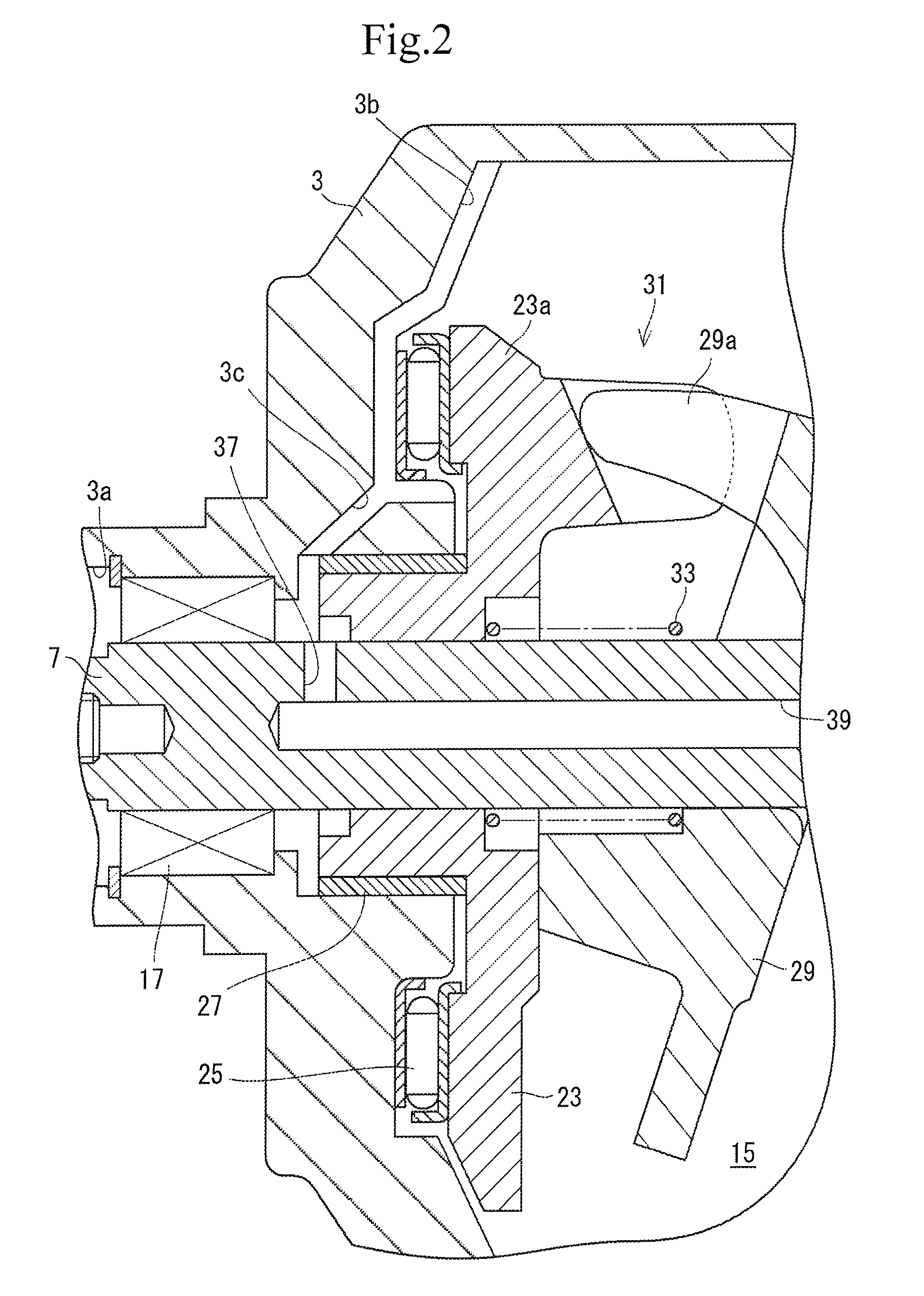

[0027]A swash plate compressor according to EMBODIMENT 1 is of a variable displacement type used for air-conditioning of a vehicle. As shown in FIG. 1, the compressor includes a housing composed of a cylinder block 1, a front housing 3 and a rear housing 5, and a plurality of cylinder bores 1a extending in parallel to an axis of a drive shaft 7 are provided on the cylinder block 1 to extend therethrough. In addition, the left in FIG. 1 indicates the front of the compressor and the right indicates the rear of the compressor.

[0028]Formed on the rear housing 5 are a suction chamber 11 and a discharge chamber 13, which are communicated to the respective cylinder bores 1a through a valve unit 9. Also, the front housing 3 and the cylinder block 1 define a crank chamber 15 and axial holes 3a, 1b are formed on the front housing 3 and the cylinder block 1. A shaft seal device 17 is provided in the axial hole 3a. A rubber material is used for the shaft seal device 17. Also, a plain bearing 19...

embodiment 2

[0052]With a swash plate compressor according to EMBODIMENT 2, a plurality of cylinder bores 2a extending in parallel to an axis of a drive shaft 8 are provided on a cylinder block2 to extend therethrough as shown in FIG. 6. Formed on a rear housing 6 are a suction chamber 12 and a discharge chamber 14, which are communicated to the respective cylinder bores 2a through a valve unit 10. Also, a front housing 4 and the cylinder block 2 define a crank chamber 16 and axial holes 4a, 2b are formed on the front housing 4 and the cylinder block 2. A shaft seal device 18 and a plain bearing 20 are provided in the axial hole 4a. A rubber material is used for the shaft seal device 18. Also, a plain bearing 22 is provided in the axial hole 2b. A receiving chamber 2c communicated to the axial hole 2b is formed centrally of a rear end of the cylinder block 2, the receiving chamber 2c being opposed to the valve unit 10.

[0053]The drive shaft 8 is supported by the shaft seal device 18, etc. in a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com